Embossed Stainless Steel Sheet metal with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321/410/420/430/444/443/409L,and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

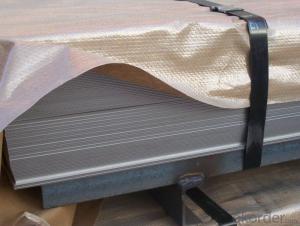

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Cold Rolled and Hot Rolled:

Packing and Loading:

FAQ:

1. What's the quality?

Very fine, we have been exported to more than 30 countries.

2. How long get reply?

Usually within 24 hours

If you have any question about stainless steel sheets, do not forget to send the email to us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What are the factors to consider when selecting the right grade of stainless steel sheet?

- When selecting the right grade of stainless steel sheet, there are several important factors to consider. These include the intended application and environment, desired corrosion resistance, strength requirements, temperature resistance, and budget constraints. Additionally, factors like fabrication ease, availability, and aesthetic preferences should also be taken into account. Ultimately, it is crucial to carefully evaluate these factors in order to choose the most suitable grade of stainless steel sheet for your specific needs.

- Q: How are stainless steel sheets installed?

- Stainless steel sheets are typically installed using a few different methods, depending on the specific application and requirements. Here are some common installation methods for stainless steel sheets: 1. Adhesive: One of the simplest and most common methods is using an adhesive to bond the stainless steel sheet to the desired surface. An adhesive specifically designed for stainless steel is applied to the back of the sheet, which is then pressed firmly onto the surface. This method works well for flat or slightly curved surfaces and provides a clean and seamless installation. 2. Mechanical fasteners: For applications where additional strength and stability are required, stainless steel sheets can be installed using mechanical fasteners such as screws, bolts, or rivets. These fasteners are drilled or screwed through the sheet and into the surface to secure it in place. This method is commonly used for installations that need to withstand external forces or for attaching stainless steel sheets to structural components. 3. Welding: In some cases, particularly for large or complex installations, welding may be used to connect stainless steel sheets together or to other metal structures. Welding creates a strong and permanent bond between the sheets, ensuring a secure installation. However, this method requires skilled professionals and specialized equipment to ensure proper welding techniques and prevent damage to the stainless steel. 4. Magnetic attachment: Some stainless steel sheets are designed with a magnetic backing, allowing them to be easily attached to magnetic surfaces. This method is quick and convenient, as the sheets can be easily repositioned or removed if needed. However, it is important to ensure that the magnetic surface is clean and free from debris that could affect the adhesion. Before installing stainless steel sheets, it is crucial to properly prepare the surface by cleaning it thoroughly and removing any dirt, dust, or grease. This will help ensure a secure and long-lasting installation. Additionally, following the manufacturer's instructions and guidelines for the specific stainless steel sheet being installed is essential to achieve the best results.

- Q: How thick is 10gauge in stainless steel plate?

- The word "gauge" is interesting. This term is often seen in articles reading about metal roofs. It is not a unit of measurement, but a standard measure of width or thickness.

- Q: Can stainless steel sheets be cold rolled?

- Indeed, it is possible to cold roll stainless steel sheets. The cold rolling process involves passing a stainless steel sheet through a sequence of rollers at ambient temperature, leading to a decrease in thickness and an augmentation in both hardness and strength. By employing this technique, one can create stainless steel sheets with accurate measurements and impeccable surface textures. Cold rolling is widely utilized in the production of stainless steel sheets, catering to diverse sectors including automotive parts, kitchen devices, and architectural constructions.

- Q: What does stainless steel sheet S2 stand for?

- Stainless steel sheet S2 stands for thickness 2mm

- Q: Can stainless steel sheets be embossed or textured?

- Yes, stainless steel sheets can be embossed or textured. This process involves imprinting patterns or designs onto the surface of the stainless steel sheets, adding visual interest and texture to the material.

- Q: What is the cost of stainless steel sheets?

- The price of stainless steel sheets may differ based on various factors including the thickness, size, and grade of stainless steel employed. Typically, stainless steel sheets are priced per square foot or square meter. The price range can further be influenced by the supplier, location, and market conditions. Moreover, any additional processing or finishing requirements like polishing or cutting can impact the overall cost. To obtain precise and current pricing details for stainless steel sheets, it is advisable to reach out to a local supplier or distributor.

- Q: Can stainless steel sheets be used in swimming pool applications?

- Yes, stainless steel sheets can be used in swimming pool applications. Stainless steel is a popular choice for swimming pool construction due to its durability, resistance to corrosion, and aesthetic appeal. Stainless steel sheets can be used for various purposes in swimming pools, such as pool walls, floors, stairs, and water features. They offer excellent strength and are highly resistant to corrosion caused by chlorine and other chemicals present in pool water. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for swimming pool applications.

- Q: Can stainless steel sheets be used for food preparation surfaces?

- Food preparation surfaces can indeed utilize stainless steel sheets. The reason behind stainless steel's popularity for such surfaces is its remarkable characteristics. Being non-porous, it avoids the absorption of any liquids or bacteria that can contaminate the food. Moreover, stainless steel exhibits resistance to corrosion, staining, and rusting, thereby ensuring its durability and longevity for food preparation surfaces. Furthermore, stainless steel can be easily cleaned due to its ability to withstand high temperatures and resistance to most cleaning agents. This fact makes it a hygienic option for food preparation surfaces, as it allows for thorough sanitization to prevent bacterial growth. In conclusion, stainless steel sheets provide a secure and practical alternative for food preparation surfaces.

- Q: How do I prevent stress relaxation on stainless steel sheets?

- Stainless steel sheets undergo stress relaxation when exposed to high temperatures or constant stress. To prevent stress relaxation in stainless steel sheets, the following measures can be taken: 1. Carefully choose the stainless steel grade: Different grades of stainless steel have different resistance to stress relaxation. Opt for a grade with high resistance, such as austenitic stainless steels like Type 304 or Type 316. 2. Avoid excessive temperatures: Operate the stainless steel sheets within the recommended temperature range. Exposing them to temperatures beyond this range can accelerate stress relaxation. Ensure that the operating temperature remains within the permissible limits. 3. Control stress levels: Minimize stress during fabrication and installation. Do not excessively bend, stretch, or deform the material, as this introduces stress. Properly design and fabricate components to reduce stress concentration points. 4. Consider post-weld heat treatment: If the stainless steel sheets are welded, consider performing heat treatment after welding. This involves subjecting the welded area to controlled heating and cooling cycles to relieve residual stresses and minimize the potential for stress relaxation. 5. Reduce exposure to aggressive environments: While stainless steel sheets are corrosion-resistant, exposure to aggressive chemicals or environments can accelerate stress relaxation. Avoid prolonged exposure to corrosive substances or environments that can compromise the material's integrity and cause stress relaxation. 6. Regularly inspect and maintain: Periodically inspect the stainless steel sheets for signs of stress relaxation, such as deformation, cracks, or dimensional changes. Regular maintenance and timely repairs can help identify and address any issues before they worsen. 7. Seek advice from experts: If unsure about preventing stress relaxation in stainless steel sheets, consult metallurgical experts or stainless steel manufacturers. They can provide guidance on the best practices and materials to ensure long-term performance and prevent stress relaxation. By implementing these preventive measures, the risk of stress relaxation in stainless steel sheets can be significantly reduced. This ensures their durability and maintains their structural integrity over time.

Send your message to us

Embossed Stainless Steel Sheet metal with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords