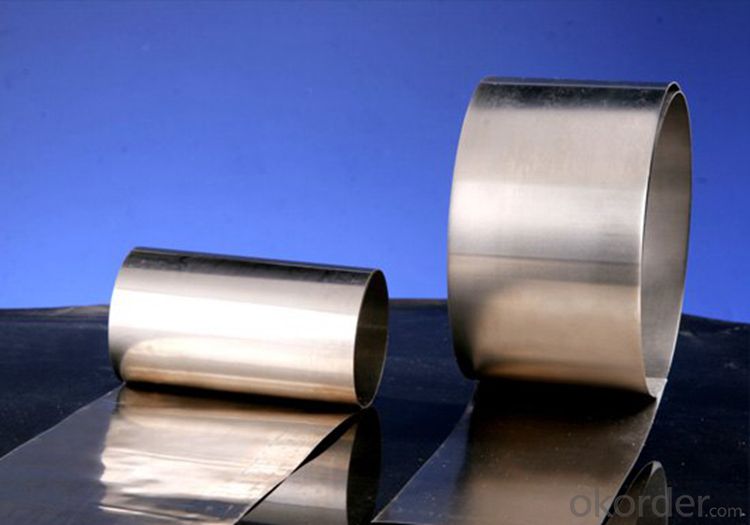

Cold Rolled Stainless Steel Sheets Grade 304,Stainless Steel Coils NO.2B Finish from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: How do you remove adhesive from stainless steel sheets?

- One effective way to remove adhesive from stainless steel sheets is by applying a small amount of rubbing alcohol or acetone to a soft cloth and gently rubbing the adhesive residue. Another option is to use a mixture of warm water and mild soap, followed by scrubbing with a non-abrasive sponge or cloth. If the adhesive is particularly stubborn, using a commercial adhesive remover specifically designed for stainless steel can also be effective.

- Q: Can stainless steel sheets be used for brewery tanks?

- Brewery tanks can indeed utilize stainless steel sheets. In the brewing industry, stainless steel is widely employed due to its exceptional resistance to corrosion, strength, and hygienic characteristics. It is a non-reactive material, meaning it does not interact with the beer or modify its flavor, consequently ensuring the purity and quality of the final product. By shaping and welding stainless steel sheets, tanks of various sizes and shapes can be created, making them suitable for a broad range of brewing applications. Moreover, stainless steel is effortless to clean, maintain, and sanitize, which is crucial for preserving the cleanliness and sterility of brewery tanks. In summary, stainless steel sheets are an ideal choice for brewery tanks due to their durability, chemical resistance, and hygienic properties.

- Q: Are stainless steel sheets resistant to pitting?

- Yes, stainless steel sheets are resistant to pitting. Stainless steel has a high resistance to corrosion, including pitting corrosion, due to its chromium content which forms a protective oxide layer on the surface. This makes stainless steel sheets a durable and reliable material for various applications where resistance to pitting is important.

- Q: Are stainless steel sheets suitable for cleanroom applications?

- Yes, stainless steel sheets are suitable for cleanroom applications. Stainless steel has excellent corrosion resistance, which is important in cleanroom environments where cleanliness and hygiene are crucial. It is also highly durable and easy to clean, making it ideal for maintaining cleanliness standards in cleanrooms. Additionally, stainless steel is non-porous, which means it does not absorb contaminants and can be easily sanitized. It is also resistant to chemicals, making it suitable for cleanroom applications where strong disinfectants or cleaning agents may be used. Overall, stainless steel sheets offer a reliable and hygienic surface for cleanroom applications.

- Q: How do stainless steel sheets differ from other types of metal sheets?

- Stainless steel sheets differ from other types of metal sheets primarily due to their unique composition, which includes a high percentage of chromium. This gives stainless steel sheets superior resistance to corrosion, staining, and rusting, making them highly durable and ideal for various applications in industries such as construction, automotive, and kitchenware. Additionally, stainless steel sheets are known for their aesthetic appeal, as they have a smooth, reflective surface finish.

- Q: Are stainless steel sheets suitable for automotive body panels?

- Absolutely! Automotive body panels can definitely benefit from the use of stainless steel sheets. This material is widely favored in the automotive industry because of its remarkable ability to resist corrosion and its exceptional durability. It can withstand even the harshest weather conditions, making it perfect for body panels. Moreover, stainless steel sheets provide a sleek and polished look, enhancing the overall aesthetic appeal of the vehicle. Furthermore, stainless steel offers a superior strength-to-weight ratio, resulting in better fuel efficiency and improved vehicle performance. In conclusion, stainless steel sheets are an incredibly reliable and long-lasting choice for automotive body panels.

- Q: Can stainless steel sheets be used for countertops or backsplashes?

- Yes, stainless steel sheets can be used for countertops and backsplashes. Stainless steel is a durable and hygienic material that is resistant to stains, heat, and corrosion, making it a popular choice for kitchen surfaces.

- Q: What is the maximum width available for stainless steel sheets?

- The stainless steel sheet's maximum width can differ based on the manufacturer and supplier. Typically, you can find stainless steel sheets with widths between 36 inches (0.91 meters) and 72 inches (1.83 meters). Certain manufacturers may provide wider options for specialized purposes. To ensure accuracy, it's recommended to consult the specific supplier or manufacturer regarding the maximum width as it may vary depending on their production capabilities and product range.

- Q: Are stainless steel sheets environmentally friendly?

- Stainless steel sheets are considered to be environmentally friendly for several reasons. First and foremost, stainless steel is a highly durable and long-lasting material. Unlike other materials such as plastic or wood, stainless steel sheets do not deteriorate easily and have a lifespan of several decades. This means that they do not need to be frequently replaced, reducing the amount of waste generated. Additionally, stainless steel is 100% recyclable. At the end of its life cycle, stainless steel can be melted down and reused to create new products, without losing any of its original properties. This significantly reduces the demand for raw materials and the energy required for manufacturing new products. Furthermore, stainless steel sheets are non-toxic and do not release harmful chemicals into the environment. Unlike some plastics or treated woods, stainless steel does not emit VOCs (volatile organic compounds) or other pollutants that can contribute to air or water pollution. Stainless steel is also corrosion-resistant, which means that it requires minimal maintenance and does not require chemicals or coatings to protect it from rust or degradation. This reduces the reliance on environmentally harmful substances and minimizes the release of pollutants into the environment. In summary, stainless steel sheets are considered to be environmentally friendly due to their durability, recyclability, non-toxic nature, and resistance to corrosion. These qualities make stainless steel a sustainable and responsible choice for various applications, ranging from construction to household appliances.

- Q: How do stainless steel sheets compare to other types of metal sheets?

- Stainless steel sheets possess numerous advantages that distinguish them from alternative metal sheets. Firstly, stainless steel exhibits a high level of resistance to corrosion, rendering it an optimal selection for applications where durability and longevity are of utmost importance. Unlike other metals, stainless steel does not readily rust or stain, thereby guaranteeing the preservation of its appearance and functionality even in challenging environments. Secondly, stainless steel sheets are renowned for their strength and robustness. They possess a significant tensile strength, enabling them to endure heavy loads without undergoing bending or warping. This attribute renders stainless steel sheets suitable for a wide array of applications, including the construction, automotive, and manufacturing industries. Another notable advantage of stainless steel sheets lies in their hygienic properties. Stainless steel is non-porous and non-absorbent, facilitating easy cleaning and maintenance. Additionally, it exhibits resistance to bacterial growth, making it a favored choice for medical equipment, food processing facilities, and kitchen appliances. Furthermore, stainless steel sheets offer exceptional heat resistance. They can withstand high temperatures without compromising their structural integrity or developing any deformities, making them suitable for applications involving extreme heat or thermal cycling. Lastly, stainless steel sheets are available in a variety of finishes and textures, granting versatility in terms of design options. Whether one prefers a polished, brushed, or matte finish, stainless steel allows for customization to fulfill any aesthetic requirement. In conclusion, stainless steel sheets surpass other types of metal sheets due to their exceptional resistance to corrosion, strength, hygienic properties, heat resistance, and aesthetic versatility. These qualities establish stainless steel sheets as the preferred choice for numerous industries, ensuring durability, reliability, and longevity across various applications.

Send your message to us

Cold Rolled Stainless Steel Sheets Grade 304,Stainless Steel Coils NO.2B Finish from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords