200,300,400 series Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

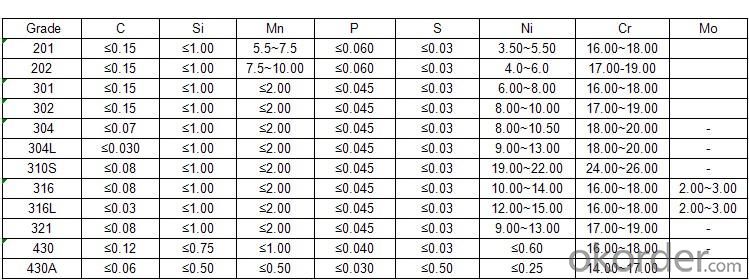

2. Chemical Composition about stainless steel sheet

3. Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff

- Q: 904L stainless steel plate generally used in what industry is more?

- With high chromium content and adequate content of nickel, copper to make it strong acid resistant ability, especially for chloride crevice corrosion and stress corrosion cracking are highly resistant, not prone to pitting and cracking, pitting resistance slightly better with other steel, with good machinability and welding that can be used for pressure vessel.

- Q: What are the fire resistance properties of stainless steel sheets?

- Stainless steel sheets have excellent fire resistance properties due to their unique composition and structure. Unlike other materials, stainless steel does not readily burn or ignite when exposed to high temperatures. This is primarily because stainless steel contains a high percentage of chromium, which forms a thin, protective oxide layer on the surface of the material when exposed to air. This oxide layer acts as a barrier, preventing the underlying steel from reacting with oxygen and further resisting fire. Furthermore, stainless steel has a high melting point, typically around 1400-1450°C (2552-2642°F), which is significantly higher than most common building materials. This means that stainless steel sheets can withstand extreme heat without deforming or losing their structural integrity, providing additional fire protection. Additionally, stainless steel is non-combustible, meaning it does not contribute to the fuel load of a fire. This characteristic is particularly important in construction and industrial applications, where fire safety is a top priority. Overall, the fire resistance properties of stainless steel sheets make them an ideal choice for various applications, including building construction, transportation, and industrial settings, where fire protection is necessary.

- Q: What are the benefits of using brushed stainless steel sheets?

- There are several benefits of using brushed stainless steel sheets. Firstly, brushed stainless steel has an attractive and sleek appearance, making it a popular choice for various applications such as appliances, countertops, and backsplashes. The brushed finish gives the metal a unique texture and a matte appearance, which adds a touch of sophistication to any space. Secondly, brushed stainless steel sheets are highly durable and resistant to corrosion, making them suitable for both indoor and outdoor use. This material is known for its strength and ability to withstand harsh conditions, such as chemicals, moisture, and extreme temperatures. It is also easy to clean and maintain, as the brushed finish helps to hide fingerprints, smudges, and scratches. Additionally, brushed stainless steel sheets are hygienic and resistant to bacteria growth, making them ideal for applications in the food and medical industries. The smooth surface of the metal makes it easy to clean and disinfect, ensuring a safe and sanitary environment. Furthermore, brushed stainless steel sheets offer excellent longevity and longevity, making them a cost-effective investment. This material is known for its resistance to wear and tear, meaning it can withstand heavy use and maintain its appearance for many years without needing to be replaced. Lastly, brushed stainless steel sheets are versatile and can be easily customized to fit different design preferences. They can be cut, shaped, and formed into various sizes and shapes, allowing for endless design possibilities. Whether you prefer a modern, industrial look or a more traditional and elegant style, brushed stainless steel sheets can be tailored to suit your specific needs. In conclusion, the benefits of using brushed stainless steel sheets include their attractive appearance, durability, corrosion resistance, hygienic properties, longevity, and versatility. Whether for residential, commercial, or industrial use, brushed stainless steel sheets offer a wide range of advantages that make them a popular choice for many applications.

- Q: Are stainless steel sheets suitable for water tanks?

- Yes, stainless steel sheets are suitable for water tanks. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for water storage. It is durable, long-lasting, and can withstand high water pressures. Additionally, stainless steel is hygienic, easy to clean, and does not contaminate the water.

- Q: Can stainless steel sheets be used for water purification systems?

- Water purification systems can utilize stainless steel sheets. Due to its resistance to corrosion, durability, and hygienic properties, stainless steel is commonly chosen as a material for water purification systems. It can withstand harsh environmental conditions without rusting, making it suitable for long-term use in water treatment applications. Furthermore, stainless steel does not react with water, ensuring the purity and safety of the treated water by not leaching harmful substances. Its smooth and non-porous surface is easy to clean and maintain, reducing the risk of bacterial growth and contamination. In conclusion, stainless steel sheets are an excellent option for constructing various components of water purification systems, such as tanks, filters, and pipes.

- Q: Can stainless steel sheets be used for bus shelters?

- Yes, stainless steel sheets can be used for bus shelters. Stainless steel is a durable and weather-resistant material, making it suitable for outdoor applications like bus shelters. It offers longevity, easy maintenance, and a modern aesthetic.

- Q: Can stainless steel sheets be used for escalator steps?

- Yes, stainless steel sheets can be used for escalator steps. Stainless steel is a popular choice for escalator steps due to its durability, strength, and resistance to corrosion. It can withstand the constant foot traffic, heavy loads, and the wear and tear that escalator steps are subjected to on a daily basis. Additionally, stainless steel has a sleek and modern appearance, which adds to the overall aesthetic appeal of escalators. This makes stainless steel sheets a reliable and practical choice for escalator steps in various commercial and public settings.

- Q: What are the common manufacturing standards for stainless steel sheets?

- The common manufacturing standards for stainless steel sheets include ASTM A240, ASME SA240, EN 10028-7, and JIS G4304. These standards specify the chemical composition, mechanical properties, tolerances, and surface finishes required for stainless steel sheets used in various industries.

- Q: Are stainless steel sheets suitable for chemical reactors?

- Chemical reactors can utilize stainless steel sheets as they possess favorable properties for this purpose. The chemical industry often opts for stainless steel due to its exceptional resistance to corrosion. It can withstand a broad spectrum of chemicals, including acids, alkalis, and solvents, without experiencing significant deterioration or reacting with the substances being processed. The selection of stainless steel sheets for chemical reactors is primarily based on their high strength, durability, and ability to withstand high temperatures and pressure. They can endure the challenging conditions and aggressive substances encountered in chemical processes, all while maintaining their structural integrity. Furthermore, stainless steel sheets are easy to clean and maintain, making them well-suited for applications where cleanliness is of utmost importance, such as the pharmaceutical and food processing industries. They also exhibit excellent heat transfer properties, enabling efficient temperature control within the reactor. In conclusion, stainless steel sheets are a dependable option for chemical reactors due to their corrosion resistance, strength, durability, and thermal properties. They offer a secure and long-lasting solution for handling various chemicals, making them widely utilized in the chemical industry.

- Q: Can stainless steel sheets be used for decorative lighting fixtures?

- Yes, stainless steel sheets can certainly be used for decorative lighting fixtures. Stainless steel is a versatile and durable material that can be shaped and formed into various designs and patterns, making it ideal for creating unique and eye-catching lighting fixtures. Its sleek and modern appearance adds a touch of elegance to any space, making it a popular choice for decorative purposes. Additionally, stainless steel is resistant to corrosion and heat, ensuring that the lighting fixtures will remain in excellent condition for a long time.

Send your message to us

200,300,400 series Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords