Stainless Steel Sheets Steel Plates 200 Series 300 Series 400 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

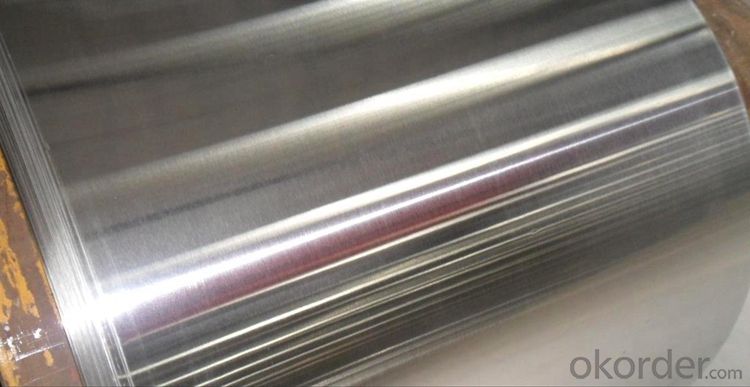

Detail picture for Stainless Steel Coils/Sheets

Application of Stainless Steel Coils

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can stainless steel sheets be used for hygienic environments?

- Yes, stainless steel sheets can be used for hygienic environments. Stainless steel is a popular choice for such environments due to its inherent properties that make it highly resistant to corrosion, heat, and chemical damage. Its smooth and non-porous surface is easy to clean, preventing the accumulation of bacteria, mold, or other contaminants. Stainless steel is also non-reactive and does not release any harmful substances, making it suitable for sensitive environments such as food processing facilities, hospitals, pharmaceutical labs, and cleanrooms. Additionally, stainless steel is durable and long-lasting, providing excellent hygiene and cleanliness for extended periods. Overall, stainless steel sheets are a reliable and hygienic choice for various applications in environments that prioritize cleanliness and sanitation.

- Q: Can stainless steel sheets be used for countertops?

- Certainly! Countertops can indeed be made using stainless steel sheets. Stainless steel is a material known for its durability and versatility, as it possesses resistance against stains, heat, and bacteria. Consequently, it proves to be an exceptional option for kitchen countertops. Moreover, stainless steel countertops are effortless to clean and maintain, all while presenting a sleek and contemporary look. While commonly found in commercial kitchens, these countertops are steadily gaining popularity in residential settings, owing to their durable nature and hygienic qualities.

- Q: How do I prevent fingerprints or smudges on stainless steel sheets?

- To prevent fingerprints or smudges on stainless steel sheets, you can try using a microfiber cloth or a soft cotton cloth to wipe the surface regularly. Avoid using abrasive cleaners or scrub brushes that can cause scratches. Additionally, you can use a stainless steel cleaner or a mixture of water and mild dish soap for deeper cleaning.

- Q: Can stainless steel sheets be customized in terms of size and shape?

- Yes, stainless steel sheets can be customized in terms of size and shape. Stainless steel is a highly versatile material that can be easily manipulated and transformed to meet specific requirements. Whether it is a large sheet or a small one, stainless steel can be cut, shaped, and resized to fit the desired dimensions. This customization process can be achieved through various techniques such as cutting, bending, welding, and forming. Additionally, stainless steel sheets can also be perforated or embossed to add further customization and enhance their aesthetic appeal. Overall, stainless steel sheets offer great flexibility in terms of size and shape customization, making them suitable for a wide range of applications in industries such as construction, automotive, aerospace, and more.

- Q: Are stainless steel sheets suitable for cryogenic applications?

- Yes, stainless steel sheets are suitable for cryogenic applications. Stainless steel is known for its excellent mechanical properties, including high strength and toughness, which make it suitable for low-temperature environments. Additionally, stainless steel has good corrosion resistance, which is crucial when exposed to cryogenic temperatures. It maintains its mechanical properties and does not become brittle at ultra-low temperatures. Therefore, stainless steel sheets are commonly used in cryogenic applications such as storage tanks, pipelines, and equipment for liquefied natural gas (LNG), liquid nitrogen, and other cryogenic fluids.

- Q: Are stainless steel sheets suitable for outdoor staircases?

- Yes, stainless steel sheets are suitable for outdoor staircases. Stainless steel is known for its durability, resistance to corrosion, and ability to withstand harsh weather conditions, making it an excellent choice for outdoor applications. Stainless steel sheets provide a sleek and modern look while ensuring strength and stability. Additionally, stainless steel is low maintenance and easy to clean, making it a practical choice for outdoor staircases that are exposed to dirt, dust, and other outdoor elements.

- Q: What is the impact strength of stainless steel sheets?

- The impact strength of stainless steel sheets can vary depending on several factors, such as the grade and thickness of the stainless steel, as well as the specific conditions under which the impact occurs. Generally, stainless steel has a good level of impact strength due to its inherent properties, including its high tensile strength and ductility. Stainless steel is known for its ability to withstand impacts and resist deformation, making it a preferred material in various industries where durability is crucial. It exhibits excellent resistance to impact loading, which means it can withstand sudden impact forces without fracturing or breaking. This makes stainless steel sheets suitable for applications that require high impact resistance, such as structural components, automotive parts, and machinery. However, it is important to note that different grades of stainless steel have varying impact strengths. Some grades, such as austenitic stainless steels (e.g., 304 and 316), have excellent impact resistance due to their high nickel and chromium content. On the other hand, ferritic and martensitic stainless steels may have slightly lower impact strengths. In addition to grade, the thickness of the stainless steel sheet also plays a role in determining its impact strength. Thicker sheets generally have higher impact resistance compared to thinner ones, as they can absorb more energy before yielding or fracturing. It is worth mentioning that the impact strength of stainless steel can be further enhanced through various methods, including heat treatment and alloying. These processes can improve the material's toughness and resistance to impact loading. Overall, stainless steel sheets have a good impact strength that is suitable for many applications. However, it is recommended to consult the specific grade and thickness specifications, as well as any industry standards or regulations, to determine the exact impact strength requirements for a particular application.

- Q: What is the price range for stainless steel sheets?

- The price range for stainless steel sheets can vary depending on a few factors such as the thickness, size, and grade of the stainless steel. Generally, the price range for stainless steel sheets starts at around $30 per square foot for thinner sheets and can go up to $150 per square foot for thicker or higher-grade sheets. It's important to note that prices can also be influenced by market conditions and supplier pricing policies, so it's always a good idea to compare prices from different suppliers before making a purchase.

- Q: What kind of screws do you choose for stainless steel plates?

- Because boards are often used for decoration, the best choice is not to be fixed with screwsJust use good glue, OKIf the plate is for other purposes, if the demand is not high, ordinary will do

- Q: How are stainless steel sheets used in the construction industry?

- Stainless steel sheets are commonly used in the construction industry for various applications. They are used to create durable and corrosion-resistant structures such as roofs, walls, and facades. Additionally, these sheets are often used to manufacture components like beams, columns, and frames due to their strength and versatility. Stainless steel sheets are also frequently employed for interior finishes and decorative purposes, as they provide a sleek and modern appearance. Overall, stainless steel sheets play a crucial role in construction, contributing to the longevity and aesthetic appeal of buildings.

Send your message to us

Stainless Steel Sheets Steel Plates 200 Series 300 Series 400 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords