Single-component PU Concrete Waterproofing Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

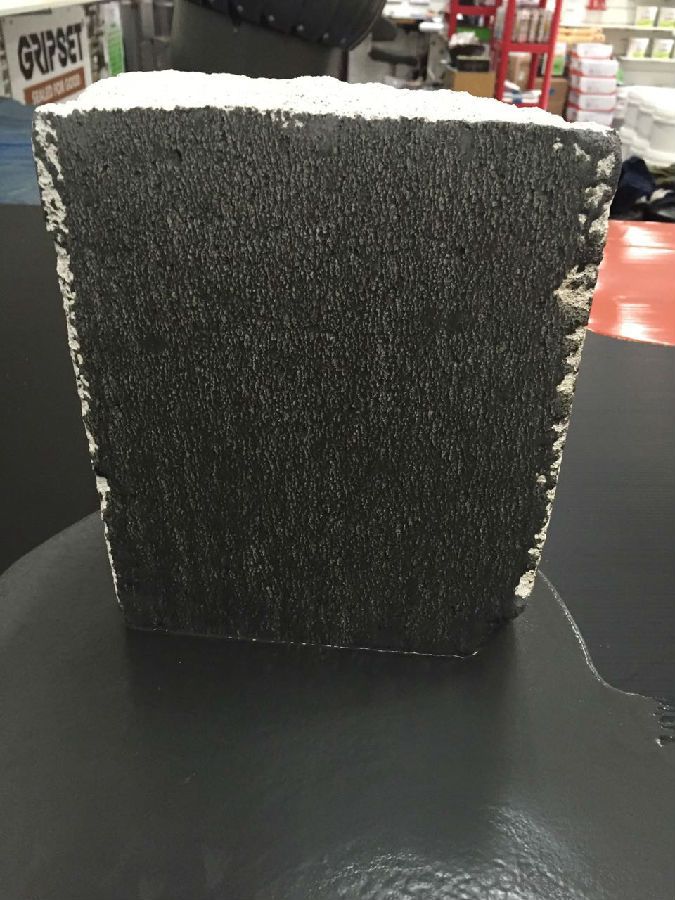

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: How to do waterproof bathroom, construction process is what

- First, the bathroom waterproof method: 1, brush the first time waterproof coating. Before the construction to ensure that the ground dry, waterproof coating to be painted, no omission, and the combination of solid grass, no cracks, no bubbles, no shedding phenomenon. Brushing the same height, the thickness of the product requirements to meet the requirements.

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 2, when the basement depth is large, it is impossible to dig a place in time, you can use the reverse construction method, that is, dig a certain depth, then finished a section of retaining wall, to be a certain strength, and then open Dig, do the next retaining wall, and in this order until the construction to the specified design depth.

- Q: What decoration materials, light and water, and the wall, the perfect combination of glass

- Four, pressure glue Hold the 45 ° angle along the gap to press out the glass compound to ensure that the glass compound is in close contact with the substrate surface. Glue gun moving speed according to the size of the gap, the depth of the line evenly move the glue gun, cloth evenly full, do not pile material and broken. When the seam width is greater than 15 mm, need to repeatedly glue.

- Q: What material waterproofing can be mixed with cement sand

- Construction can also be used to produce waterproof pulp, waterproofing agent for the amount of cement 3 ‰ -4 ‰, the use of cement label not less than 32.5MPa.

- Q: There is no formaldehyde in the finished putty

- Visible putty powder and formaldehyde or a great relationship, but now many manufacturers have introduced environmentally friendly putty powder, not only environmentally friendly pollution-free important is also can control the air, there is a negative ion putty powder is the composition which contains tourmaline tourmaline, through And the water molecules in the air combined with the decomposition of negative ions to deal with the air, anion can be neutralized with formaldehyde into dust falling into the air, you can also remove the dust in the air, as well as enhance the metabolism of the function.

- Q: Roof leakage, what materials do the best waterproof

- Therefore, rainy days should not be construction, to wait until the sun will dry the water before construction. The roof of a large area of ??leakage or a number of water leakage points, the first by the professionals to check whether the cracks, according to the previous program to deal with the cracks in the roof covered with waterproofing membrane, to enhance the waterproof effect, you can also shop On the insulation board, because the height of the insulation board in 20 cm or more, to achieve the protection of waterproof layer and thermal insulation of the double effect. Do not want to use the insulation board of the family, you can consider the use of steel mesh concrete, leak-proof effect is also very good. Wall cracks appear seepage, under normal circumstances the professional construction team will use the basket, by the maintenance staff in the external wall construction.

- Q: What are the key points and contents of the quality control of waterproof material?

- 1, polymer cement waterproof coating: it consists of a variety of water-based polymer emulsion and a variety of additives mixed with high-quality cement powder composition. Because of its high cost of polymer emulsion components (about 19,000 yuan / T), and the low cost of powder (about 800 yuan / T), it is because the liquid material, powder huge spread, the vast majority of fraud is to use 801 Glue + fossil powder + green dyestuff + cement blending; the other is to change the liquid material, the proportion of powder will be your liquid material consumption, as much as possible to increase the amount of powder. Resulting in poor waterproof coating adhesion, intolerance, after the completion of the finished product should not be too hard to pull down by hand, and was not much ductility of the sheet or even hand rub a few times into a powder, with blisters Will break down into small pieces. Can also be used to cut the finished product coating and then placed in the refrigerator freezer room after 8 hours to remove, gently forced to break will be broken, and the national standard requirements of the material to achieve low temperature flexibility -10 ℃.

- Q: I would like to ask how to do in the warm water above,

- I do not do 80% of the warm water, of course, the use of good quality water pipes, waterproof water is generally done in the following to do, if done in the warm tube above will affect the heat of the floating, to warm the following covered with a Layer insulation layer and then covered with warm tube to, and then beat the water to ensure that no leakage. And finally in the above covered with wooden floor or floor tiles.

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 4: sauna board ????This is a dedicated wood panel for the sauna, but it can also be used in the kitchen and bathroom, generally degreased, with high temperature, not easy to deformation, health and environmental protection and other characteristics, even if there is a long time in the water Will not rot, usually painted in a layer of paint decoration, can make the overall ceiling more beautiful.

- Q: How does the waterproofing membrane work?

- 4, rolling the membrane: the first turn up the end of 1m long, with a long torch melting the bottom of the hot melt adhesive, the rapid paste fixed on the grassroots, and then re-harvest the rest of the volume. The gunmen stood on the paved webs, aligned with the corners of the rolls and the surface of the base layer with the flame of the long gun, and slowly rolled the edges by melting the hot melt. The web is pasted on the base;

Send your message to us

Single-component PU Concrete Waterproofing Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords