Polyvinyl Chloride (PVC) Roofing Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

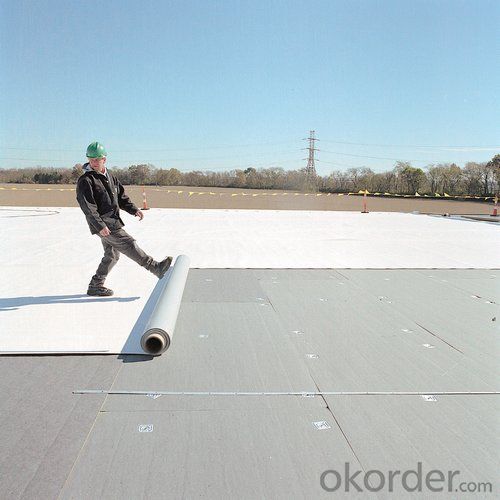

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Specification

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

Features and Benefits:

a) High Strength

b) Hot-air welded seams for long-term performance

c) Proven membrane performance

d) Excellent resistance to plasticizer extraction and migration performance.

Usage:

a) Roofing (covered & exposed roofs)/ Re- roofing

b) Tunnel Lining

c) Tanking of Underground structures

d) Lining of evaporation ponds & artificial lakes

e) Lining of drinking water tanks & swimming pools

f) Agricultural purposes & Lining of irrigation canals

RFQ

1. What is your MOQ?

--Our MOQ is 5000 m2

2. Can you provide sample?

--Yes, samples are in stock. we can offer free sample for you.

3. Do you offer OEM service?

--Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Can a waterproofing membrane be used for a commercial building roof?

- Yes, a waterproofing membrane can be used for a commercial building roof. Waterproofing membranes are commonly used in commercial roofing systems to provide a durable and effective barrier against water penetration. These membranes are designed to withstand the challenges of commercial buildings, such as exposure to the elements, foot traffic, and mechanical equipment. They offer excellent protection against leaks, moisture damage, and other potential roofing issues, making them a suitable choice for commercial applications.

- Q: Can a waterproofing membrane be used for crawl spaces or basements?

- Yes, a waterproofing membrane can be used for crawl spaces or basements. In fact, it is one of the most effective methods to prevent water infiltration and moisture issues in these areas. Waterproofing membranes are designed to create a protective barrier against water, preventing it from seeping into the crawl space or basement. They are typically made from durable materials such as rubber, PVC, or polyethylene, which are resistant to water penetration. These membranes are installed on the walls and floors of the crawl space or basement, creating a watertight seal. This helps to keep the area dry, prevent water damage, and reduce the risk of mold and mildew growth. Additionally, waterproofing membranes can also act as a vapor barrier, preventing moisture from evaporating from the ground and entering the crawl space or basement. Overall, using a waterproofing membrane is a recommended solution for maintaining a dry and healthy crawl space or basement.

- Q: Can a waterproofing membrane be used in new construction?

- Yes, a waterproofing membrane can be used in new construction. In fact, it is often recommended to install a waterproofing membrane during the construction phase to provide an added layer of protection against water damage. Waterproofing membranes are typically applied to the exterior foundation walls and basement floors to prevent water infiltration and to create a barrier against moisture. This can help to prevent issues such as leaks, mold, and structural damage in the future. Additionally, waterproofing membranes can also be used in other areas of a new construction project, such as roofs, balconies, and bathrooms, to ensure long-lasting waterproofing protection. Overall, using a waterproofing membrane in new construction can help to prolong the lifespan of the building and provide peace of mind for the occupants.

- Q: Can a waterproofing membrane be used as a vapor barrier?

- Yes, a waterproofing membrane can be used as a vapor barrier. Waterproofing membranes are designed to prevent the passage of water through a surface, such as a roof or foundation. In the process of preventing water penetration, these membranes also act as a vapor barrier, stopping the movement of water vapor. This helps to reduce the risk of condensation and moisture-related issues within a structure. However, it is important to note that not all waterproofing membranes are created equal and may have different levels of vapor resistance. Therefore, it is essential to select a waterproofing membrane that is specifically designed to also act as a vapor barrier if that is a requirement for the intended application.

- Q: Can a waterproofing membrane be used for art installations or sculptures?

- Indeed, the utilization of a waterproofing membrane is applicable for art installations and sculptures. In the realm of construction projects, waterproofing membranes are commonly employed to ward off water infiltration and safeguard surfaces from potential moisture damage. Concerning art installations and sculptures, a waterproofing membrane can furnish added durability and fortification against environmental factors like rain, snow, or humidity. This becomes particularly crucial for outdoor installations or sculptures that are exposed to the elements. Furthermore, the implementation of a waterproofing membrane can aid in preserving the artwork's integrity and longevity, ensuring its enduring visual appeal and structural soundness. Nevertheless, it is imperative to seek guidance from professionals or experts in the field of waterproofing to ensure the appropriate selection and application of the membrane, as certain artistic materials or techniques may necessitate specific types.

- Q: Can a waterproofing membrane be used on glass block surfaces?

- No, a waterproofing membrane cannot be used on glass block surfaces as they are already inherently waterproof.

- Q: Can a waterproofing membrane be used on planter boxes?

- Planter boxes can indeed benefit from the use of a waterproofing membrane. Typically employed to prevent water from seeping through surfaces, a waterproofing membrane safeguards the wood or other materials of the planter box from moisture damage. When applied to the interior, this membrane acts as a barrier, stopping water from infiltrating the material and potentially causing decay or rot. Consequently, the planter box's lifespan is prolonged, ensuring it remains in excellent condition for an extended period. Moreover, the waterproofing membrane aids in retaining moisture within the planter box, which proves advantageous for the growth of plants or flowers. Overall, the application of a waterproofing membrane enhances protection and durability for planter boxes.

- Q: Can a waterproofing membrane be used for loading dock levelers and pit walls?

- Indeed, loading dock levelers and pit walls can benefit from the utilization of a waterproofing membrane. These membranes are specifically engineered to offer a shielding barrier against the infiltration of moisture and water. Applying a waterproofing membrane to loading dock levelers and pit walls serves to counteract water seepage and the potential harm induced by moisture. This serves as a crucial measure, particularly in areas where water exposure is a considerable concern, such as loading docks and pits that experience constant exposure to rain, snow, or water from cleaning activities. The waterproofing membrane establishes an impervious barrier that ensures the foundational structures remain dry and safeguards them from possible water-related complications such as corrosion, mold proliferation, and deterioration.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- A waterproofing membrane is created to resist punctures or tears, being made from robust materials like PVC, TPO, or EPDM, renowned for their strength and damage resistance. These membranes undergo extensive testing to ensure they can endure different environmental conditions and potential causes of punctures or tears, like sharp objects or heavy foot traffic. Some waterproofing membranes even have reinforcement layers or added protection to further strengthen their resistance to punctures and tears. Nevertheless, it is crucial to note that while waterproofing membranes are highly durable, they are not entirely immune to damage. Proper installation, regular maintenance, and avoiding unnecessary stress or impact on the membrane can help extend its lifespan and enhance its performance.

- Q: Can a waterproofing membrane be used in parking garages?

- Parking garages can benefit greatly from the use of a waterproofing membrane. Due to their exposure to various weather conditions and heavy vehicular traffic, these structures are susceptible to moisture infiltration and structural damage. Therefore, it is crucial to install a dependable waterproofing system to safeguard against water penetration and potential deterioration. A waterproofing membrane serves as an effective solution for parking garages by acting as a barrier against water and moisture. It is typically composed of durable materials such as modified bitumen, PVC, or EPDM, which are resistant to water intrusion. When applied to the concrete surface, the membrane forms a protective layer that prevents water from seeping through. By preventing moisture from penetrating the concrete, the waterproofing membrane not only defends the parking garage against water infiltration but also helps to prolong its lifespan. This, in turn, reduces the risk of corrosion, deterioration of reinforcing steel, and the formation of cracks. Ultimately, the structural integrity of the parking garage is maintained, saving on costly future repairs or replacements. Moreover, a waterproofing membrane can offer additional advantages, including resistance to chemicals, UV radiation, and abrasion. This makes it an ideal solution for parking garages that face harsh environmental conditions and heavy traffic. To summarize, the use of a waterproofing membrane is highly recommended for parking garages. It provides reliable protection against water infiltration, helps to maintain the structure's integrity, and extends its lifespan.

Send your message to us

Polyvinyl Chloride (PVC) Roofing Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords