Geomembrana Ldpe

Geomembrana Ldpe Related Searches

Geomembrana Lldpe Geomembrana Hdpe Hdpe Geomembrana Geomembran Hdpe Geomembrana De Hdpe Geomembrana In Hdpe Geomembrana Hdpe 2mm Wholesale Hdpe Geomembrana Geomembrane Hdpe Geomembrana Hdpe 1mm Lldpe Geomembrane Liner Geomembrane In Hdpe Geomembrana Hdpe Sodimac Gse Hdpe Geomembrane Lldpe Geomembrane Specifications Hdpe Geomembrane Machine Wholesale Geomembrane Hdpe Hdpe Textured Geomembrane Geomembrana Hdpe 1 Mm Precio Geomembrana Hdpe 2 Mm Precio Pegamento Para Geomembrana Hdpe Hdpe Geomembrane China Rollo De Geomembrana Hdpe Geomembrana Hdpe 40 Mils Hdpe Smooth Geomembrane Reinforced Hdpe Geomembrane Wholesale Hdpe Geomembrane Hdpe Geomembrane Sheet Hdpe Membrane Jual Geomembrane HdpeGeomembrana Ldpe Supplier & Manufacturer from China

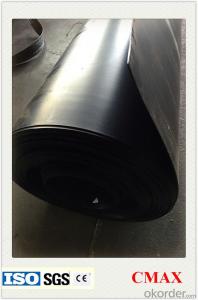

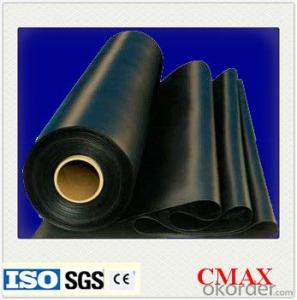

Geomembrana LDPE is a high-quality, flexible, and durable plastic sheeting material that is widely used in various industries. It is specifically designed to provide excellent waterproofing and containment capabilities, making it an ideal choice for applications such as landfill liners, canal lining, reservoirs, and waste containment facilities. The product's unique properties, such as its chemical resistance, UV resistance, and flexibility, make it a popular choice for a wide range of projects.Geomembrana LDPE is utilized in various applications where waterproofing and containment are crucial. It is commonly used in civil engineering projects, environmental protection, and construction industries. The product's versatility allows it to be tailored to specific project requirements, ensuring optimal performance and durability. Its ability to withstand harsh environmental conditions and resist chemical degradation makes it a reliable solution for long-term projects.

Okorder.com is a reputable wholesale supplier of Geomembrana LDPE, offering a vast inventory of this product to cater to the needs of various industries. As a leading supplier, Okorder.com ensures that customers receive high-quality materials at competitive prices, along with excellent customer service and support. By partnering with Okorder.com, customers can be confident that they are receiving the best Geomembrana LDPE products for their specific applications.