LDPE Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LDPE Geomembranes

Products Description

This product is extruded PE membrane formed by adding anti- oxidant, absorbent of ultraviolet and dyestuff into HDPE or LDPE or EVA and will provide an effective barrier to of liquid

water and water vapor.

Characteristics

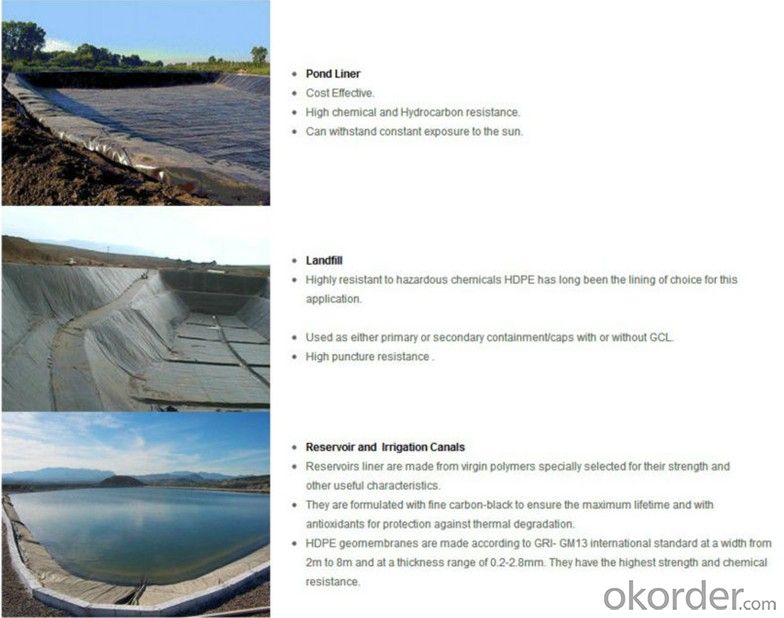

·HDPE performs well in mechanical properties ,ageing-resistance , chemical-resistance ,climate- resistance and

resistance to puncture .

·LDPE & EVA feathers great elongation, good flexibility at low temperature, softness and easy

installation.

·ECB ,high-class waterproofing rolls, is formed by combining ethylene polymer with oil-resin.

Products Specification

Name | Thickness(mm) | Width(m) |

HDPE | 0.75-2.5 | 4-8 |

LDPE | 0.2-2.5 | 4-8 |

EVA | 0.2-2.5 | 2-8 |

ECB | 1.0-2.0 | 2-8 |

Features:

1.All physical factors such as anti-draw, anti-tear, and anti-stab meet the requirement of water works, chemicals, tunnels,

and transportation project in most conditions.

2.Good aging, durable performance, and wide temperature range, it can be useful over

thirty years on the condition of -60æ«60æ.

3.Anti-stab and fine friction factors.

4.Canker proof, acid and alkali proof, untoxic.

5.Lower cost per unit area, cost is 1/3«1/2 lower than that of PVC film, glass and cloth.

6.Convevient to install and dependable effect.

Application Rage

- Q: Can a waterproofing membrane prevent water leakage in basements?

- Indeed, basements can be shielded from water leakage through the use of a waterproofing membrane. This membrane, whether applied externally or internally, serves as a protective shield against water infiltration by coating the walls of the basement. By doing so, it effectively halts water from seeping through the foundation walls, thus preventing any potential leaks or moisture-related problems within the basement. Acting as a watertight seal, the membrane ensures that water is unable to enter the basement, effectively safeguarding the structure from any harm that water damage may inflict. Nonetheless, it is crucial to acknowledge that the efficacy of a waterproofing membrane hinges on its correct installation and regular upkeep.

- Q: Are there any specific considerations for installing a waterproofing membrane on concrete surfaces?

- Yes, there are several specific considerations for installing a waterproofing membrane on concrete surfaces. Firstly, it is important to ensure that the concrete surface is clean, dry, and free from any loose materials, oil, grease, or other contaminants. Any dirt or debris on the surface can prevent proper adhesion of the waterproofing membrane, compromising its effectiveness. Secondly, it is crucial to inspect the concrete surface for any cracks, spalling, or other damage. These defects should be repaired prior to installing the waterproofing membrane, as they can allow water to penetrate through the membrane and compromise its ability to protect the concrete. Additionally, the type of waterproofing membrane chosen should be suitable for the specific conditions and requirements of the project. There are various types of membranes available, such as sheet membranes, liquid-applied membranes, or cementitious coatings. Each type has different application methods, durability, flexibility, and resistance to various substances, so it is important to select the appropriate membrane for the specific concrete surface and its intended use. Furthermore, the installation of the waterproofing membrane should be carried out in accordance with the manufacturer's instructions. This includes applying the membrane at the recommended thickness, ensuring proper overlap and adhesion of the membrane seams, and using any recommended primers or adhesives. Lastly, it is important to consider the long-term maintenance and durability of the waterproofing membrane. Regular inspections, maintenance, and repairs should be conducted to ensure the membrane remains intact and effective in preventing water penetration.

- Q: Can a waterproofing membrane be used for elevator shafts or equipment rooms?

- Yes, a waterproofing membrane can be used for elevator shafts or equipment rooms. Elevator shafts and equipment rooms are often exposed to moisture and water infiltration, which can lead to damage to the equipment and structural components. Therefore, it is crucial to have a reliable waterproofing solution in place to prevent water penetration. A waterproofing membrane is a commonly used method to protect elevator shafts and equipment rooms from water damage. It is a thin layer of material that is applied to the surfaces of the shaft or room, acting as a barrier against water intrusion. These membranes are typically made from various materials such as bitumen, PVC, or EPDM, which have excellent waterproofing properties. The waterproofing membrane is applied to all exposed surfaces, including walls, floors, and ceilings, to create a seamless and watertight enclosure. It is designed to withstand hydrostatic pressure and prevent water from seeping into the elevator shaft or equipment room. Additionally, the membrane can also provide protection against other forms of moisture, such as condensation. Furthermore, waterproofing membranes can be combined with other waterproofing techniques, such as sealants and drainage systems, to enhance their effectiveness. This multi-layered approach ensures a comprehensive waterproofing solution for elevator shafts and equipment rooms. In conclusion, a waterproofing membrane is a suitable solution for elevator shafts and equipment rooms, as it offers reliable protection against water infiltration. Its application creates a watertight enclosure, preventing potential damage to the equipment and structural components in these areas.

- Q: Does a waterproofing membrane provide any insulation against heat or cold?

- No, a waterproofing membrane does not provide any insulation against heat or cold. While it is designed to prevent water from penetrating into the building, it does not have any insulating properties to regulate temperature. Insulation is typically achieved through separate materials such as foam boards, fiberglass, or other thermal barriers that are installed alongside the waterproofing membrane to provide thermal resistance and regulate temperature.

- Q: Can a waterproofing membrane be used for underground fuel storage tanks?

- Yes, a waterproofing membrane can be used for underground fuel storage tanks. The membrane helps to prevent the infiltration of water into the tank, protecting it from corrosion and potential leaks.

- Q: Can waterproofing membranes be used on concrete countertops?

- Concrete countertops can indeed benefit from the application of waterproofing membranes. These membranes are specially crafted to thwart the infiltration of water and can be utilized on diverse surfaces, including concrete. By opting for a waterproofing membrane on a concrete countertop, one can effectively safeguard it against water harm, staining, and possible structural concerns. Furthermore, these membranes can augment the countertop's resilience and lifespan by averting moisture-induced problems, such as cracking or warping. It is imperative to verify that the selected waterproofing membrane is concrete-compatible and appropriate for countertop use.

- Q: Can a waterproofing membrane be used in laundry rooms?

- Yes, a waterproofing membrane can be used in laundry rooms. Laundry rooms are areas where water and moisture are commonly present due to washing machines, sinks, and other water-related activities. Installing a waterproofing membrane in the laundry room can help prevent water damage to the walls, floors, and other structural components. It acts as a barrier against water penetration, ensuring that any water or moisture that accumulates in the room does not seep into the underlying surfaces. This can be particularly beneficial in laundry rooms located on upper floors or in areas prone to high humidity or flooding. By using a waterproofing membrane, homeowners can protect their laundry rooms from potential water-related issues, such as mold growth, rotting, or structural damage.

- Q: Are waterproofing membranes environmentally friendly?

- Depending on the type and installation, waterproofing membranes have the potential to be environmentally friendly. Some membranes are manufactured with recycled materials, which reduces the need for new resources and waste generation. Moreover, certain membranes are designed for durability and longevity, reducing the frequency of replacement and overall environmental impact. Nevertheless, it is crucial to consider the potential adverse environmental effects of waterproofing membranes. Some membranes are composed of synthetic materials that may release harmful chemicals into the environment during production or degradation. Furthermore, improper installation or disposal of these membranes can result in pollution and contamination of soil and water sources. To ensure the environmental friendliness of waterproofing membranes, it is essential to select products certified as sustainable or eco-friendly by reputable organizations. Additionally, hiring experienced professionals for correct installation minimizes the risk of leaks or damage that could lead to environmental issues. Lastly, proper disposal of old or damaged membranes is vital to prevent pollution and ensure responsible waste management. In conclusion, waterproofing membranes can be environmentally friendly if appropriate materials are chosen, installation is performed correctly, and disposal is handled responsibly. It is crucial to assess the environmental impact of these membranes and make informed choices to minimize any negative effects.

- Q: Is a waterproofing membrane resistant to UV radiation?

- Typically, a waterproofing membrane is resistant to UV radiation. Most manufacturers design these membranes to be durable and long-lasting, ensuring they can withstand exposure to UV rays. Over time, UV radiation from the sun can cause degradation and damage to various materials, including waterproofing membranes. To combat this, manufacturers often include UV stabilizers and additives in the membrane's composition. These additives prevent the breakdown of the membrane's structure, allowing it to remain effective in preventing water infiltration and maintaining its performance for an extended period, even when exposed to direct sunlight. Some waterproofing membranes may also have a protective layer or coating that offers extra UV resistance. To understand the specific UV resistance capabilities of a particular waterproofing membrane, it is advisable to consult the manufacturer's specifications and guidelines.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels or flooding?

- Yes, a waterproofing membrane can be used in areas with high groundwater levels or flooding. Waterproofing membranes are designed to provide a barrier against water infiltration and can effectively protect structures from water damage. These membranes are typically made of materials such as bitumen, rubber, or synthetic polymers, which are impermeable to water. They are applied on various surfaces such as foundations, basements, roofs, and walls to prevent water penetration. In areas with high groundwater levels or frequent flooding, the use of a waterproofing membrane becomes even more crucial. The membrane acts as a protective layer, preventing water from seeping into the structure and causing potential damage. It ensures that the interior of the building remains dry and free from water-related issues such as mold, mildew, and structural deterioration. However, it's important to consider the specific conditions of the site and the level of groundwater or flooding. In some extreme cases, where water pressure is high or flooding is prolonged, additional waterproofing measures may be necessary, such as installing a drainage system or using thicker and more robust membranes. Consulting with a professional waterproofing contractor or engineer is recommended to ensure the appropriate membrane system is chosen and installed correctly for the specific conditions of the site.

Send your message to us

LDPE Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords