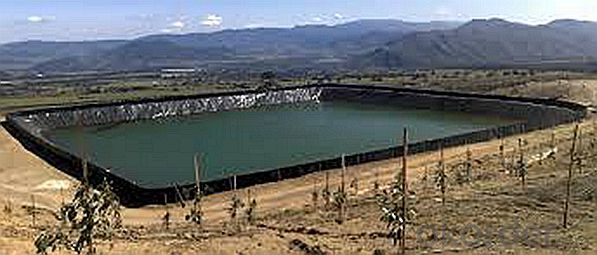

Arena Geotextiles Linear Low-Density Polyethylene (LLDPE) Geomembrane for Agriculture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Technical craft:

The HDPE geo-membrane is produced by a method of three layer co-extrusion model. The raw material is processed at 200 by fusing and coextrusion, whose basic properties are kept during the producing process.

Material 100% virgin HDPE with UV trested

Weight 130gsm to 350gsm or as your requirement

Color black or as your requirement

Width any meter as your requirement

Length any meter as your requirement

Delivery Time 7 days if we have in stock or within 20 days after the order of 20ft

UV YES

MOQ 1000 suqare meters

Terms of payment LC,TT,West union,Paypal,Cash

Supplying capacity 100 tons/month

Packing pack in roll or in bale or as your requirement

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the considerations for geotextile installation?

- Some considerations for geotextile installation include proper site preparation, ensuring the geotextile is compatible with the soil and project requirements, proper placement and anchoring techniques, and regular inspection to ensure the geotextile is functioning as intended. Additionally, factors such as weather conditions, traffic loads, and environmental considerations should also be taken into account during installation.

- Q: Can geotextile skin be connected?

- Geotextile skin can be touched. Geotextile production of raw materials is polyester fiber, polyester has been widely used in daily life. Such as clothes are also a lot of polyester material. So do not worry, geotextile is not harmful to the human body.

- Q: Geotextile water filter?

- Geotextile from the filter, filter the role of water, but soil, I am specializing in the production of geotextiles

- Q: Road with a geotextile cloth is a cloth or non-woven fabrics

- Geotextile is a non-woven category, geomembrane is divided into light film, and a cloth a film, two cloth a film, two cloth is a film in the middle of the membrane, both sides of the geotextile composite products. Huazhi geotextile material manufacturers

- Q: Geotextile thinnest how many grams

- 80-100g, I am specializing in the production of geotextile geomembrane, wish smooth

- Q: How do geotextiles help with soil separation?

- Geotextiles help with soil separation by creating a barrier between different soil layers, preventing mixing and maintaining their distinct characteristics.

- Q: What equipment is geotextile equipment?

- This I do not how clear, and detailed you can go to Long Yun machinery manufacturers to see, his home is specialized in producing this equipment manufacturers, hoping to help you to adopt.

- Q: What are the maintenance requirements for geotextile-reinforced retaining walls?

- The maintenance requirements for geotextile-reinforced retaining walls typically include regular inspections for signs of erosion, damage, or structural issues. Additionally, any vegetation growing near the wall should be monitored and removed if it poses a threat to the integrity of the structure. It is also important to ensure proper drainage and prevent water buildup behind the wall. Regular cleaning and removal of debris is necessary to avoid blockages and maintain the functionality of the drainage system. Overall, following manufacturer guidelines and conducting routine maintenance activities will help ensure the longevity and effectiveness of geotextile-reinforced retaining walls.

- Q: What are the key factors affecting the tensile strength of geotextiles?

- The key factors affecting the tensile strength of geotextiles include the type and quality of the raw materials used, the manufacturing process employed, the thickness and density of the geotextile, and the presence of any additives or coatings. Additionally, environmental factors such as temperature, moisture, and exposure to UV radiation can also influence the tensile strength of geotextiles.

- Q: Welding geotextile how to apply the mattress on or below

- Geotextile does not need welding, geotextile is geotextile, the product itself exists gaps and pores, in the project mainly play a filter, filter, reinforcement, the role of protection, can not achieve the role of anti-seepage. Generally only need to suture on it. Composite geotextile need to be welded, composite geotextile, also known as composite geomembrane, by the geomembrane through a series of production processes, the upper and lower sides were combined on the geotextile production. In the production process in each roll of composite geotextile of the four sides will be set aside 10-20cm width of the welding edge. Welding construction only need to weld the edge of the geomembrane welding, welding edge of the geotextile suture can be. Geomembrane need to be welded, geomembrane is divided into smooth geomembrane and rough geomembrane (matte geomembrane), smooth geomembrane without the need for direct laying of welding on it. Rough surface geomembrane is generally covered with wool up, welding need to remove the surface and then welding.

Send your message to us

Arena Geotextiles Linear Low-Density Polyethylene (LLDPE) Geomembrane for Agriculture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords