100% Virgin Material Landfill Geomembrane - LDPE/HDPE/LLDPE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

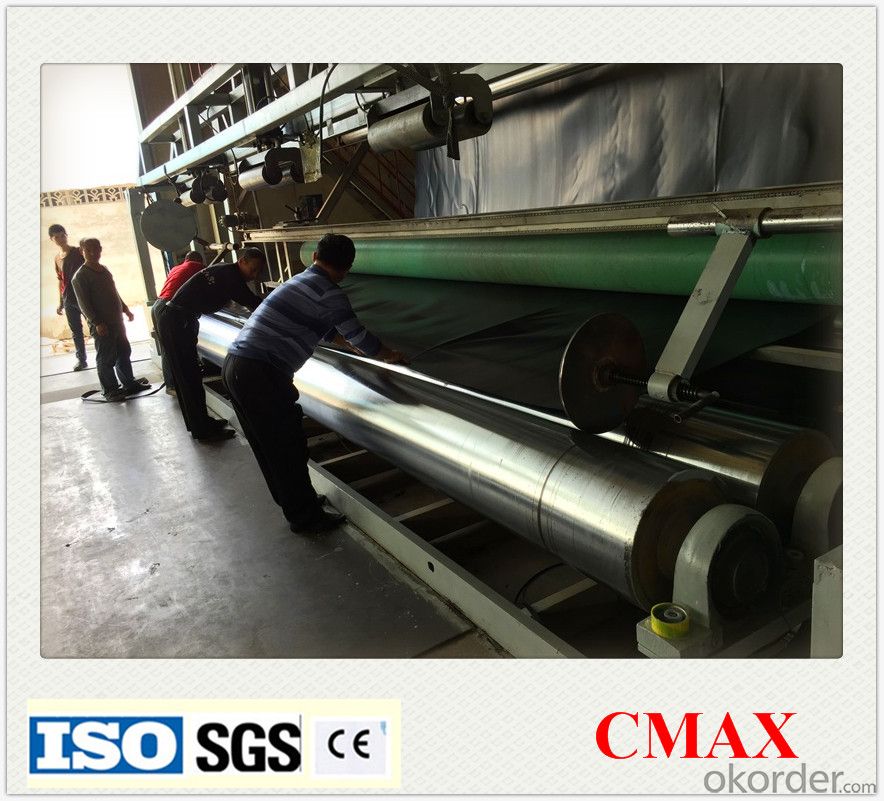

LDPE/HDPE/LLDPE Geomembrane 100% Virgin Material

Geomembrane Description

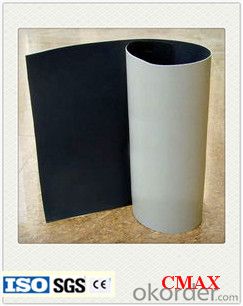

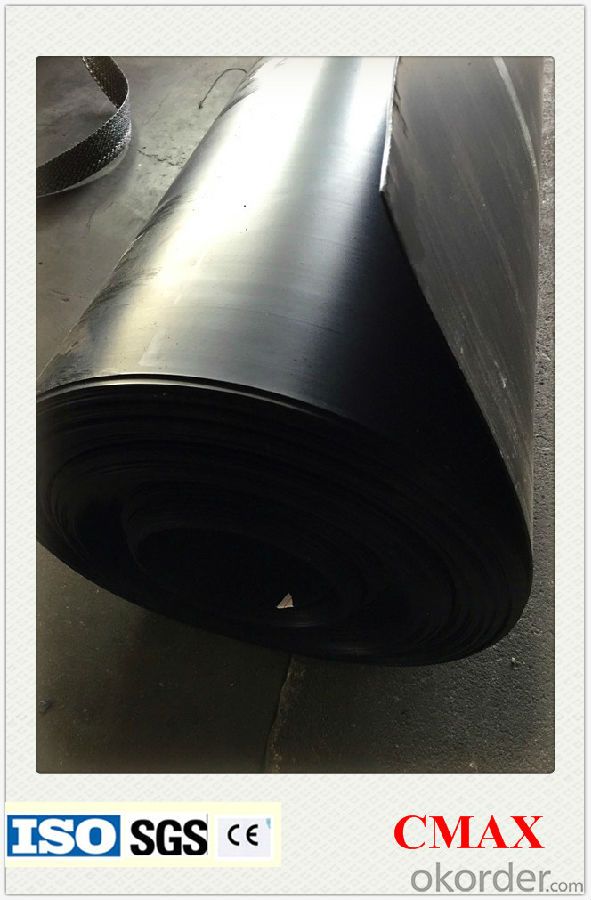

HDPE Geomembrane liner are made from polyethylene polymer materials that blow molding,its main function is to prevent the liquid leakage and gas volatile. According to the production of raw materials can divide into HDPE geomembrane liner and EVA geomembrane liner,etc.

Geomembrane Specification

1. Thickness: 0.1mm-3.0mm

2. 4m-9m in roll width, the length as clients' request.

Geomembrane Property:

Excellent waterproof, heat preservation, easy for welding, chemical and UV resistance.

Geomembrane Application:

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

5.Dike,the front of the sam foundation seepage prevention bedding,level of vertical impervious layer , construction cofferdam,waste field.

6.Seawater,freshwater fish farms.

7.Highway,the foundations of the highway and railway;the expansive soil and collapsible loess of the waterproof layer.

8.Anti-seepage of roofing

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 sqm.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Does anyone know the mechanism of ion exchange membrane

- Ion exchange resins are high molecular material with an ion exchange function. in the solution, the ion of itself will have an exchange with the ion which has the same symbol in the solution. According to the nature of different exchange groups, the ion exchange resins can be classified into two categories cation exchange resin and anion exchange resin, most of the cation exchange resin have a sulfonic acid group (-SO3H), carboxyl (-COOH) or phenol (-C6H4OH), etc. and other acidic group, wherein the hydrogen ions can have a exchange with a metal ion in solution or other cation ion, anion exchange resin containing quaternary amine [-N (CH3) 3OH], amino (-NH2 ) or imino (-NH2 ) and other alkali basic group. They can generate OH- ions in water, which can have the exchange interaction with various anions, and the ion exchange resin is in very widely use, it is mainly used for the isolation and purification.

- Q: Can geomembranes be used for erosion control?

- Yes, geomembranes can be used for erosion control. They are impermeable liners made of synthetic materials that can be installed on slopes or along water bodies to prevent soil erosion. The geomembranes act as a barrier, preventing water from infiltrating the soil and carrying away sediments, thus effectively controlling erosion.

- Q: What is the role of geomembranes in industrial wastewater treatment?

- Geomembranes play a crucial role in industrial wastewater treatment by acting as a barrier to prevent the leakage or contamination of wastewater. They are used to line containment ponds, storage tanks, and other structures to effectively contain and manage the wastewater, ensuring it does not seep into the surrounding soil or groundwater. Additionally, geomembranes can also be used in the construction of wastewater treatment plants to separate different treatment stages and prevent the mixing of different types of wastewater. Overall, geomembranes provide an essential protective layer in industrial wastewater treatment infrastructure, helping to safeguard the environment and human health.

- Q: Geogrid construction should refer to what norms

- At present, there is no special geogrid reinforced soil construction specifications, can refer to the "road reinforcement soil construction technical specifications" in the provision of the belt with the requirements to do.

- Q: The difference between diamond films and diamond-like films where?

- Diamond from ultraviolet to infrared spectrum has high optical transmittance, it is an excellent corrosion-resistant materials. two preparation of diamond films are thermal chemical vapor deposition (TCVD) and plasma chemical vapor deposition (PCVD). The study is to obtain diamond film as a wear-resistant coating, the acoustic diaphragm, optical window, integrated high thermal conductivity of the substrate. it Also studied epitaxial single-crystal diamond film on a silicon wafer to prepare a diamond devices. Diamond-like carbon (DLC) is an amorphous structure, mainly carbon atom sp3 and sp2 hybrid bond. Hydrogen-containing DLC ??is also called α-C: H, wherein a hydrogen content between 20% to 50%. Hydrogen-free DLC film includes hydrogen-free amorphous carbon (α-C) and tetrahedral amorphous carbon (ta-C) film. Α-C film contains some sp3 bonds; ta-C-based film mainly contains sp3 bonds (sp3 & gt; 70%).

- Q: Can geomembranes be used in water containment systems?

- Yes, geomembranes can be used in water containment systems. They are impermeable synthetic liners that are highly effective in preventing seepage and leakage of water in various applications such as reservoirs, ponds, lakes, landfills, and wastewater treatment plants. Geomembranes provide a reliable and durable barrier to contain water, ensuring its safe storage and preventing contamination or loss.

- Q: does Landfill reservoir area include the part that is buried in the anchorage ?

- it doesn't include the area in retractable and anchoring area. the actual coverage area does not contain a linker.

- Q: How to deal with the waterproof membrane on balcony?

- 1, Cleaning the base; 2, Leveling the base with cement mortar 3, brushing one layer of JS waterproof paint and paving one layer of non-woven fabric immediately. Then brushing a layer of JS waterproof paint again (it should be noted that walls should be flanged up for 300mm); 4, After the waterproof layer is totally dried, you can do the watyer conserving test for 24 hours; 5, After draining the water, you can lay the floor tile on it (it is better to leave the seams with the width of 5mm and brush structural adhesive in it).

- Q: What is the texture wall film

- Liquid wallpaper is a pure flat printing, the texture wall film is relatively strong sense of three-dimensional

Send your message to us

100% Virgin Material Landfill Geomembrane - LDPE/HDPE/LLDPE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords