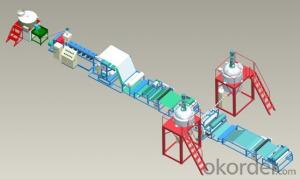

ECB Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

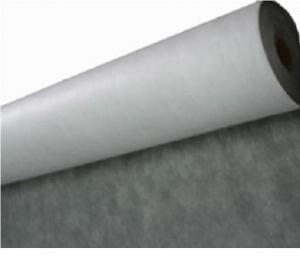

HDPE Geomembrane is a kind of waterproof material with basic raw material of high molecular polymer.

Complete variety of specifications of width and thickness. Thickness: 0.08-2mm/Width: 2-16m .

Excellent environmental stress resistant cracking performance.

Excellent performance of chemical erosion resistance.

Big scope of application temperature and long service life .

Applied in landfill waste site, sewage and filth treatment site, tailings depot and underground construction project

Items | Index | ||

LDPE | HDPE -1 | HDPE -2 | |

Tensile strength MPa | ≥14 | ≥17 | ≥25 |

Elongation at break% | ≥400 | ≥450 | ≥550 |

Right angle tearing strengthN/mm | ≥50 | ≥80 | ≥110 |

Carbon soot quantity | ≥2 | ||

Environmental stress resistant cracking performance | ≥1500 | ||

Oxidation induction time at 200min | ≥20 | ||

Permeability coefficient of vapor(g·cm/cm2·s·pa) | ≤1.0x | ||

Impact degradation performance at -70 | Pass | ||

dimension stability% | ±3 | ||

- Q: Can the cushion on the prefabricated board floor be dug?

- 1, can not be dug, the prefabricated board seam is too big. 2, in addition, now rarely used prefabricated panels, the earthquake effect is not good; especially after the Wenchuan earthquake. If it is cast-in-place floor, you can dig out.

- Q: Do you need a cushion for roof waterproofing?

- There is no "cushion" on the roof, and there is a concrete cushion under the basement floor. What you said may be leveling, is the base of the waterproof layer.

- Q: When the cushion is used, the thickness of the protective layer is not less than ()

- Not on the roof: the general waterproof layer above can be used 15 ~ 25mm cement mortar protection.

- Q: Can the floor tiles be removed from the cement mats on the prefabricated board floor?

- Prefabricated board floor layer of cement layer is not called the cushion, should be called leveling layer, this layer can be eradicated, but should pay attention not to damage.

- Q: What is the difference between leveling and cushion?

- Commonly used materials are, cement mortar leveling layer, fine stone concrete leveling layer, asphalt mortar leveling layer and so on. Leveling layer and the difference between the cushion, which is a very easy to confuse the two engineering concepts.

- Q: Is foam concrete suitable for use as a cushion?

- Inappropriate. Bubble concrete is a new type of energy-saving and environmentally friendly building materials, which are widely used in wall materials, but there are still some defects, such as low strength, cracking, water absorption, as the cushion of its strength is not enough standard.

- Q: Large area ground concrete cushion seam Why is the separation of joints generally concrete

- First, the rigid waterproof layer in a large area of ??construction, by the external force, temperature, humidity changes, structural layer deformation and other factors prone to cracking, leading to leakage, the design should consider the deformation of the waterproof layer to take the necessary Structural or structural measures to avoid and mitigate the cracking of the waterproofing layer to achieve the desired waterproofing effect.

- Q: What is the waterproof layer and the waterproof cushion in the tile roof?

- Waterproof: In order to prevent rainwater from entering the roof, groundwater infiltrates the wall, the basement and the underground structures, and the indoor water penetrates the floor and the wall.

- Q: How to build a fine stone concrete cushion?

- The main role of the cushion is to meet the requirements of the design elevation. In addition, the cushion to meet the sound insulation, insulation, insulation, slope and buried pipeline and other functional requirements and set a variety of levels.

- Q: Maintenance time of the cushion on the roof of the building

- Concrete watering maintenance time: the use of Portland cement, ordinary Portland cement or slag Portland cement mixed with concrete, not less than 7d;

Send your message to us

ECB Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords