LDPE/HDPE/LLDPE Geomembrane with Thickness 1.5 mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

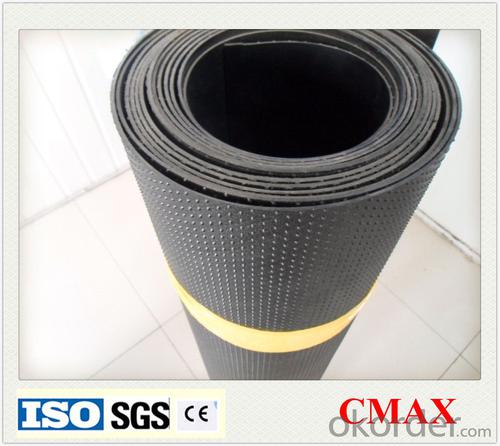

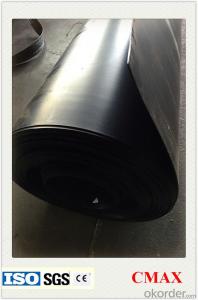

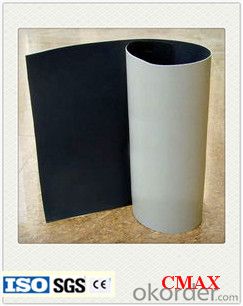

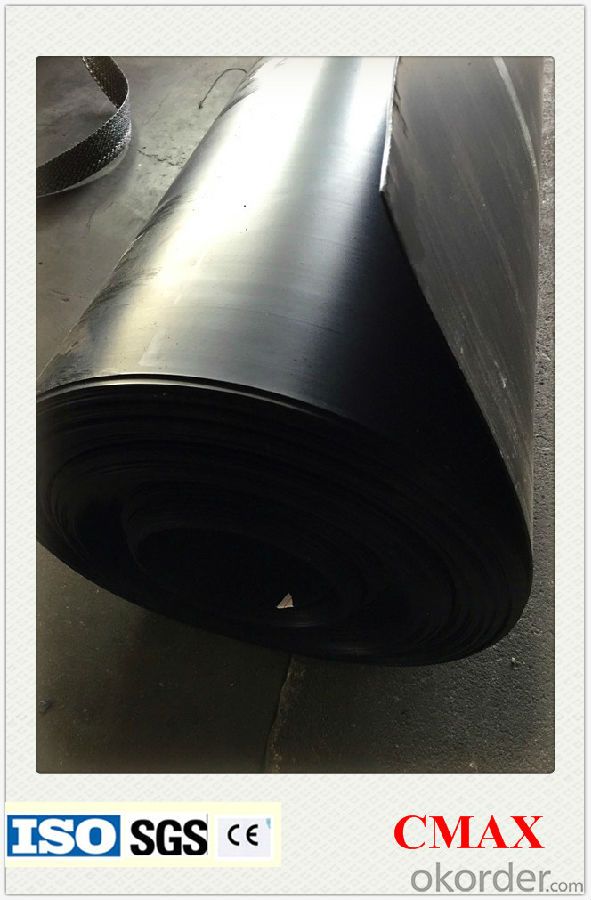

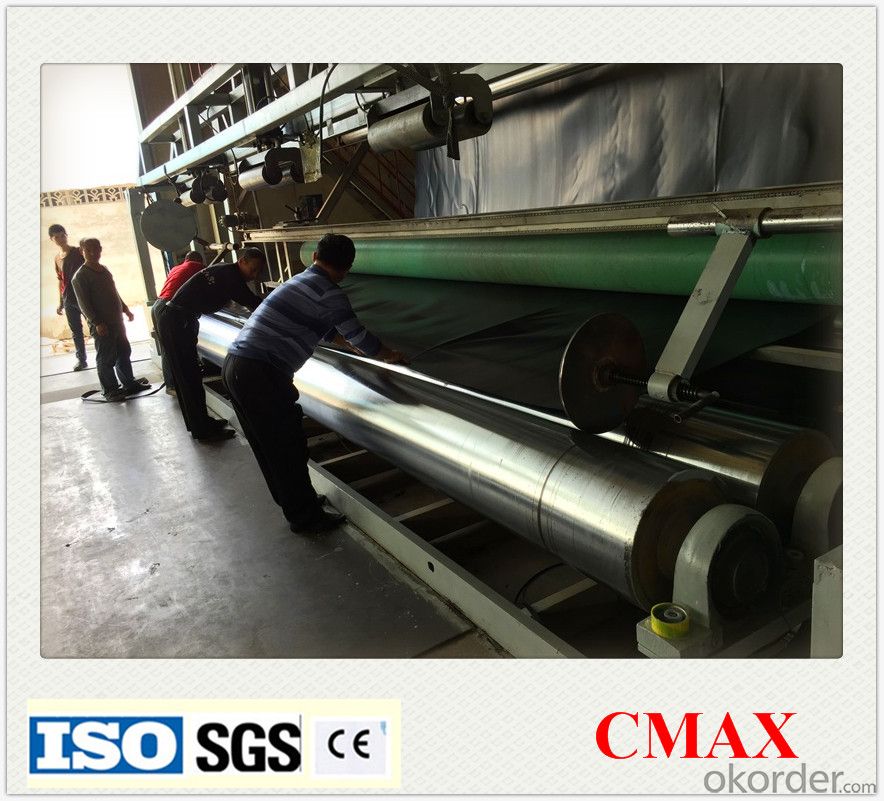

LDPE/HDPE/LLDPE Geomembrane with Thickness of 0.1mm-3.0mm

Geomembrane Description

Geomembrane is made from LDPE, LLDPE, HDPE, EVA resin and additives such as antioxidant, carbon black, master batch etc with the method of 1 layer extrusion and 3 layers co-extrusion in high temperature.

Geomembrane Specification

1. Thickness: 0.1mm-3.0mm

2. 4m-9m in roll width, the length as clients' request.

Geomembrane Property:

Excellent waterproof, heat preservation, easy for welding, chemical and UV resistance.

Geomembrane Application:

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

5.Dike,the front of the sam foundation seepage prevention bedding,level of vertical impervious layer , construction cofferdam,waste field.

6.Seawater,freshwater fish farms.

7.Highway,the foundations of the highway and railway;the expansive soil and collapsible loess of the waterproof layer.

8.Anti-seepage of roofing

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 sqm.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Are geomembranes suitable for use in potable water storage?

- Yes, geomembranes are suitable for use in potable water storage. They are impermeable and durable, preventing water leakage and contamination. Additionally, they are resistant to UV radiation and chemicals, ensuring the safety and quality of the stored water.

- Q: What are the limitations of using geomembranes in construction projects?

- Some limitations of using geomembranes in construction projects include their susceptibility to punctures or tears, limited flexibility in accommodating uneven terrain or settlement, potential for degradation over time due to UV exposure or chemical reactions, and the need for proper installation and maintenance to ensure effectiveness. Additionally, geomembranes may not be suitable for certain types of soil or site conditions, and can be relatively expensive compared to other construction materials.

- Q: What is the role of geomembranes in mining tailings management?

- Geomembranes play a crucial role in mining tailings management by providing a barrier between the tailings and the environment. They are used to contain and prevent the contamination of surrounding soil and water sources by the potentially harmful substances found in the tailings. Additionally, geomembranes can help facilitate the process of tailings dewatering and consolidation, ultimately aiding in the overall management and safety of mining operations.

- Q: Is electrothermal?film safe?

- 1, this problem is hard to answer, as long as there is electricity,there is safety hazard,

- Q: What are the differences between seepage-proof geomembrane and impermeable geomembrane?

- Just different names, products are the same.

- Q: What are the considerations for geomembrane selection in wastewater storage tanks?

- There are several important factors to consider when selecting a geomembrane for wastewater storage tanks. Firstly, the geomembrane should be chemically resistant to the specific types of wastewater being stored, as certain chemicals or substances can degrade or weaken the material. Additionally, the geomembrane should have excellent tensile strength and puncture resistance to withstand the pressure and potential impacts within the tank. The material's flexibility is also crucial to accommodate any settlement or movement of the tank without tearing. Lastly, environmental factors such as UV resistance and durability in varying temperatures should be taken into account to ensure a long lifespan for the geomembrane in the harsh conditions of wastewater storage.

- Q: How do geomembranes help with water conservation?

- Geomembranes help with water conservation by acting as a barrier to prevent the seepage of water. They are used in various applications such as lining reservoirs, ponds, and irrigation canals, effectively reducing water loss due to leakage or evaporation. Additionally, geomembranes can also be used to create impermeable caps for landfills, preventing the contamination of groundwater resources.

- Q: How do geomembranes contribute to landfill construction?

- Geomembranes play a crucial role in landfill construction by serving as a barrier that prevents the contamination of soil and groundwater. They act as a lining system, effectively containing the waste within the landfill and preventing its migration into the surrounding environment. Additionally, geomembranes help to control leachate, which is formed as a result of rainfall or decomposition of waste, by facilitating its collection and proper disposal. Overall, geomembranes ensure the long-term integrity and environmental safety of landfills.

- Q: How are geomembranes tested for tear resistance?

- Geomembranes are tested for tear resistance through various methods, including the trapezoidal tear test and the tongue tear test. These tests involve applying controlled forces to the geomembrane samples to measure their ability to resist tearing and provide valuable information about their durability and quality.

- Q: How do geomembranes perform in high altitude areas?

- Geomembranes perform well in high altitude areas due to their durability and ability to withstand extreme weather conditions. The high altitude does not significantly affect their performance as they are designed to be resistant to UV radiation, temperature fluctuations, and other environmental factors. Additionally, geomembranes provide effective containment and protection against water, chemicals, and gases, making them suitable for various applications in high altitude areas, such as water storage, mining operations, and landfills.

Send your message to us

LDPE/HDPE/LLDPE Geomembrane with Thickness 1.5 mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords