HDPE Geomembrana Black Plastic Sheeting LDPE Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Geomembranes | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX |

Model Number: | 0.1mm-4.0mm | Material: | EVA, HDPE, LDPE, LLDPE, PVC, HDPE | Thickness: | 0.1mm - 4.0mm |

Color: | white, black, red ect. | Roll width: | 1m-8m | Roll length: | 50-100m |

MOQ: | 100 m2 | Certification: | CE/ISO9001/ ISO14001 | Sample: | available for free |

Package: | by PP woven bag | Payment: | by T/T |

Packaging & Delivery

Packaging Details: | HDPE geomembrane are packed into roll in PP woven geotextile or as client' s request |

Delivery Detail: | in 10 days after receive advance payment |

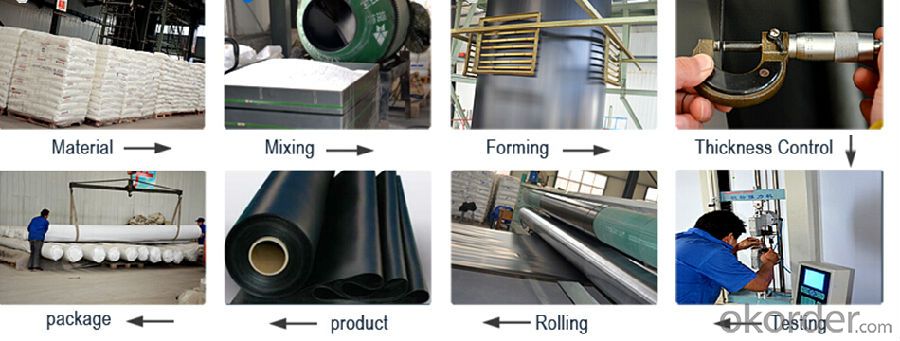

HDPE geomembrane

HDPE geomembrane specifications

1) thickness : 0.1mm - 4.0mm.

2) width : Within 8 m (1m-8m).

3) length : 50-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ,CPE).

5) Color : Black , white , red , blue , or as required.

6) Products supervised by Mr. Wang -- international geosynthetics expert.

7) Anti - UV / Anti - Aging / High Strength / anti-corrosion / high temperature-resistant / non-toxic.

8) Charge to provide the construction ( customer pay the wages of workmen) , Free to provide professional solutions.

9) Products supervised by international geosynthetics expert Mr.Wang , we also have professional engineers team provide the most professional solution for you.

HDPE geomembrane Feature

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance,

anti-aging, anti-ultraviolet-resistant,

Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water,

drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications

and low cost, simple construction.

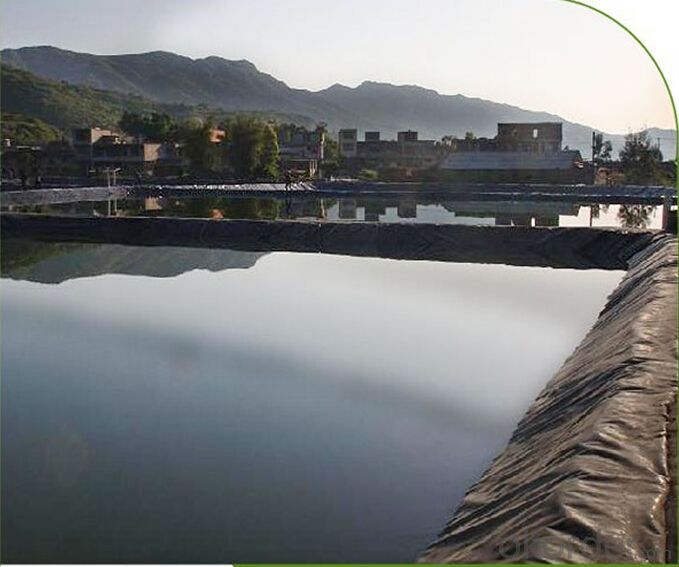

HDPE geomembrane Product Application

1) Environmental protection sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

HDPE geomembrane technical index of ASTM test GM 13 standard

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

- Q: European electrothermal?film is good

- electrothermal?film is made of polyester film. When working with electrothermal?film as a heating element, the heat is sent into space in the form of radiation , the human body and the object first get warm, and the combined effect is better than traditional convection heating. low temperature radiation electrothermal film system consists of power?supply, temperature?controller, adapting piece, insulating layer, electrothermal?film and finish?coat layer. Power supply via wires connecting the electric film, turning the electric energy into heat energy. Since the electrothermal?film is purely resistance circuit, so the high conversion is efficient, in addition to the loss of a small portion (2%), the majority (98%) is converted into heat energy. Electric film can not be directly used for radiant floor heating, it needs to add additional patent PVC vacuum envelope, thus it can be used for floor heating, and ensure the use effects and life.

- Q: Can geomembranes be used in floating covers?

- Yes, geomembranes can be used in floating covers. Geomembranes are impermeable liners that are commonly used to contain liquids and prevent seepage. When used in floating covers, they provide an effective barrier to control the evaporation of liquids such as wastewater or water storage reservoirs. The geomembrane acts as a floating layer on the surface, reducing evaporation rates and protecting the liquid from external contamination.

- Q: what are the differences between apple phone diamond film and dull polished stick membrane?

- the differences between apple phone diamond film and dull polished stick membrane: Matte stick membrane: Advantages anti-fingerprint and anti-reflective, the slide hand?feeling is good, very comfortable, non-stick fingerprints, there are small scratches and other defects which are not easily seen, the drawback is the visual effect which is not good, grainy, and the feeling like some kind of toilet atomization glass, but not so obvious; diamond film: Diamond belongs to fine grinding, the transmittance is between HD and dull polished and the photopermeability is better than dull polish membrane and it is better than high-definition diamond film pasted diamond flashing effect with more girls.

- Q: Can geomembranes be used in coastal protection projects?

- Yes, geomembranes can be used in coastal protection projects. They are a commonly employed solution for erosion control, shoreline stabilization, and coastal infrastructure protection. Geomembranes act as barriers, preventing water infiltration and soil erosion, thereby safeguarding coastal areas from wave action, tidal forces, and other natural hazards. Additionally, they can be used in the construction of coastal breakwaters, seawalls, and revetments, providing reliable and cost-effective protection against coastal erosion and flooding.

- Q: What are the capping and the foot care of the the three geomembrane grass?

- Is the construction of the anchoring ditch similar to the geotextiles?

- Q: What is the mobile phone toughened glass membrane

- Toughened glass film is also known as toughened glass film, diamond film and strengthening film glass, explosion-proof glass film is a new type of screen protection materials. Toughened glass film has made a grease proofing treatment on its surface, so that the fingerprint and the oil are not easy to stay on the surface, but easy to clean. Product thickness is 0.4mm--0.55mm, the surface hardness is 8-9H, which is 3 times of the strength of ordinary PET.

- Q: How do geomembranes withstand UV exposure?

- Geomembranes are able to withstand UV exposure due to the addition of UV stabilizers during their manufacturing process. These stabilizers help to protect the geomembrane from the harmful effects of ultraviolet radiation, such as degradation and deterioration. This allows the geomembrane to maintain its structural integrity and performance over an extended period of time, even when exposed to sunlight.

- Q: How many square meters of geomembrane is a group?

- 10,000 square meters

- Q: How to tear off the plastic wrap?

- There is a serrated knife on the plastic wrap box! Tighten it in the opposite direction. When there is a hole on the saw blade, it will be torn off easily. If you use stripped-down film roller, stroke it with a single-sided blade and it will be torn off easily. You can also loop the plastic wrap from its end into a lock and cut it off with a scissor if you don't mind the waste.

- Q: Is electrothermal film a big consumer of electricity?

- Electrothermal?film is very energy saving and comfortable.

Send your message to us

HDPE Geomembrana Black Plastic Sheeting LDPE Geomembrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords