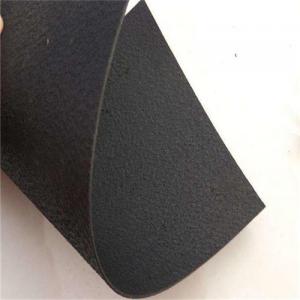

HDPE/ LDPE/LLDPE Geomembrane or Waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane Introduction:

Geomembrane is made from high grade polyethylene raw material, adding carbon black, antioxidant, antiaging and UV-resistance component.

It uses the first class automatic production equipment and three-layer pressing technology. All products are in accordance with GB, GRI and ASTM test standard.

Geomembrane Specification:

Thickness | 0.12mm-4.0mm |

Length | 50m/roll,100m/roll,150m/roll or as your choice |

Width | 5.0m-7.0m or as your choice |

Color | White/Black/Blue/Green,mainly black |

Material | HDPE |

Delivery port | Qingdao |

Package: | woven bag or as customers' requests |

Product time | 2-20 days |

Features | 1.Good physical and mechanic performance |

2.High tearing resistance, strong deformation adaptability | |

3.Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance | |

4.Good adaptability to high and low temperature, non-toxicity, long service life | |

5.Good waterproof, drainage, anti-seepage and damp proof effects | |

6.Complete width and thickness specifications, low cost and easy installation. | |

Note | We can do as your demand,please feel free to contact us for more information |

Geomembrane Application:

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

5.Dike,the front of the sam foundation seepage prevention bedding,level of vertical impervious layer , construction cofferdam,waste field.

6.Seawater,freshwater fish farms.

7.Highway,the foundations of the highway and railway;the expansive soil and collapsible loess of the waterproof layer.

8.Anti-seepage of roofing

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q: Can geomembranes be used in floating covers for water reservoirs?

- Yes, geomembranes can be used in floating covers for water reservoirs. Geomembranes are impermeable liners that can prevent water seepage and provide containment. When used as floating covers, they can effectively protect the water reservoir from evaporation, contamination, and algae growth.

- Q: Can geomembranes be used in fishpond lining?

- Yes, geomembranes can be used in fishpond lining.

- Q: Can geomembranes be used for agricultural irrigation ponds?

- Yes, geomembranes can be used for agricultural irrigation ponds. They are often employed as liners to prevent seepage and leakage of water, ensuring efficient water retention and reducing water loss in irrigation ponds.

- Q: How about sticking membrane on the window?

- It is very good. The styles of the membrane are various, enough for you to choose the one you like. It is general to use the frosted membrane in bathroom. The advantages of this membrane is that it can ensure the privacy of the room with higher heat insulation and convenience in the field of cleaning than curtain. It can let more light into the room than curtain. So there is no need to worry about the issue of daylighting.

- Q: What are the advantages of using geomembranes in radioactive waste disposal?

- One of the main advantages of using geomembranes in radioactive waste disposal is their ability to provide a strong and impermeable barrier. Geomembranes are engineered to be resistant to chemical degradation and have low permeability, which effectively prevents the migration of hazardous radioactive materials into the surrounding environment. Additionally, geomembranes are flexible and can conform to the contours of the waste disposal site, ensuring complete coverage and reducing the risk of leakage or seepage. This helps to minimize the potential for groundwater contamination and further protects the environment and public health. Moreover, geomembranes offer durability and long-term performance, even in harsh environmental conditions. They can withstand extreme temperatures, UV radiation, and mechanical stresses, ensuring the integrity of the waste disposal system over time. Furthermore, using geomembranes in radioactive waste disposal facilitates easy monitoring and maintenance. Their smooth and uniform surface allows for efficient inspection and detection of any potential issues, enabling prompt corrective actions to be taken. Overall, the advantages of using geomembranes in radioactive waste disposal include the reliable containment of hazardous materials, reduced environmental impact, long-lasting performance, and enhanced monitoring capabilities, all of which contribute to safer and more effective waste management.

- Q: Which is better, domestic or imported geomembrane?

- Although China is now also developing geomembrane, but also it is just at the beginning. Foreign environmental protection course is earlier and more developed than China's. So we have to admit that foreign HDPE geomembrane is more quality than domestic geomembrane. Although domestic geomembrane is cheaper, most of the domestic geomembrane use reused materials, so service life is greatly reduced, which is known to all. While imported HDPE geomembrane, such as geomembrane produced in Canadian Solmax International Inc. do not use reused materials, so the quality is absolutely guaranteed. Moreover, Solmax International Inc. is the world's largest and most professional supplier of HDPE geomembrane. So I think imported geomembrane has higher cost performance ratio!

- Q: What are the advantages and disadvantages of membrane pressure cupboard drawer?

- 1 the advantage of moulding pressing board cabinets : it has a good color. it will not crack after using a long time, and the deformation degree is small. The integrally molded plastic door, solves the sealing glue problem. mould pressing board is resistance to abrasion, heat, dirt, anti fade, no cracking and no deformation. Daily maintenance is simple, so it can be said that the mould pressing board is the most mature cabinet materials on the current market. Shortcomings of mould pressing panel cabinets: Because of the molding, it can not be exposure in high temperature for a long time. The bottom supporting material can not be used in the medium density board, the high intensity oppression, will lead to its deformation. If there is an open flame, the outer membrane can be burned.

- Q: What is geocell

- The geocellgeocell is formed by strengthening the HDPE sheet material, which is formed by the high strength welding, and the soil chamber is welded by ultrasonic needle. Because of the engineering needs, and some punch on the mebrane

- Q: how long can we turn on the air conditioning after screen protector?

- Summer sun is good for 2-3 days, 1-2 days of rainy weather pushed back! Winter one week!

- Q: Is there any impact on mobile phone to stick the film?

- 1, no, but it can impact on people. 2, considering that the quality of mobile phone film is different, it is not recommended to stick the film. Now, as for a lot of mobile phones, the surface of glass is very hard, which can prevent wearing, skidding and scraping, the significance of sticking the film is not great. If the quality is not good, the scratches and the oil are easy to interfere with the eyes." 3, in general, it may be good to eyes without screen protector. First, the occlusion of protective film causes the smaller light get into the eyes, resulting in insufficient light perception of eyes, so the eyes prone to light stimulation and fatigue. Second, if the cell phone film has some quality problems or a lot of scratches on the film due to the use of long time, it will produce a lot of reflected light to interfere. The ciliaris of the eyes are always in a state of tension in a long time, it will be easily damaged. 4, considering that the illuminance of the phone screen itself is relatively low, and then pasting on a layer of mobile phone film will further decline the screen transmittance, it is easier to increase the fatigue of the eyes. For a long time, the lens can not be restored to the normal state of the eye, it will form or aggravate the myopia, it is easy to do harm to vision. 5, so it is right that the mobile phone film will affect the vision. Relevant experts believe that the mobile phone film may reduce the screen transmittance and definition, it is more harmful to eyes to use the mobile phone under the weak light environment for a long time, it is not recommended to stick the mobile phone film. 6, mobile phone film is only the "booster" to harm the eyes, the main reason is the use of mobile phone "in short distance for a long time with eyes", the harm is far more harmful than looking at the computer and close reading and writing.

Send your message to us

HDPE/ LDPE/LLDPE Geomembrane or Waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords