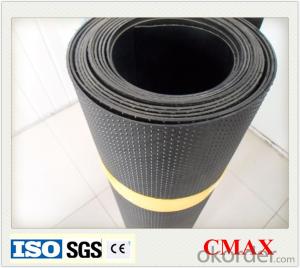

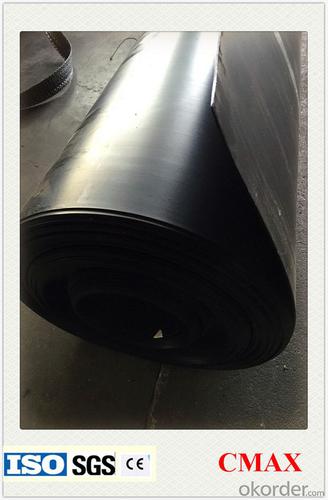

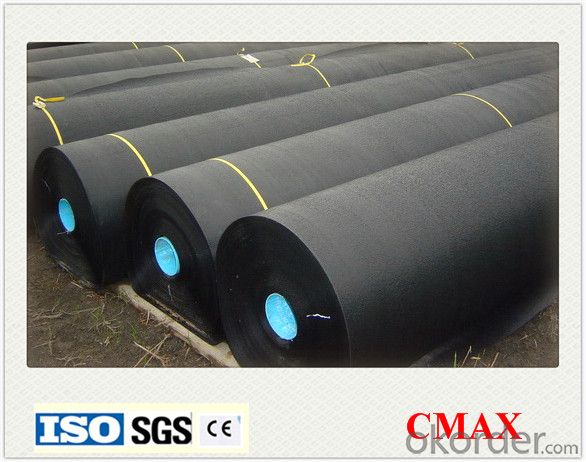

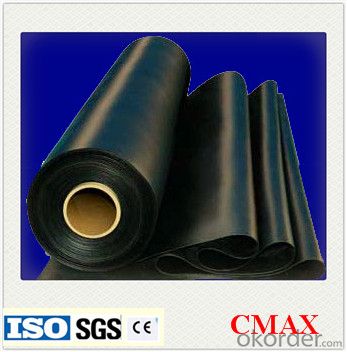

Geomembrana Hp 30 - LDPE/HDPE/LLDPE Geomembrane with Thickness 0.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

LDPE/HDPE/LLDPE Geomembrane 100% Virgin Material

Description

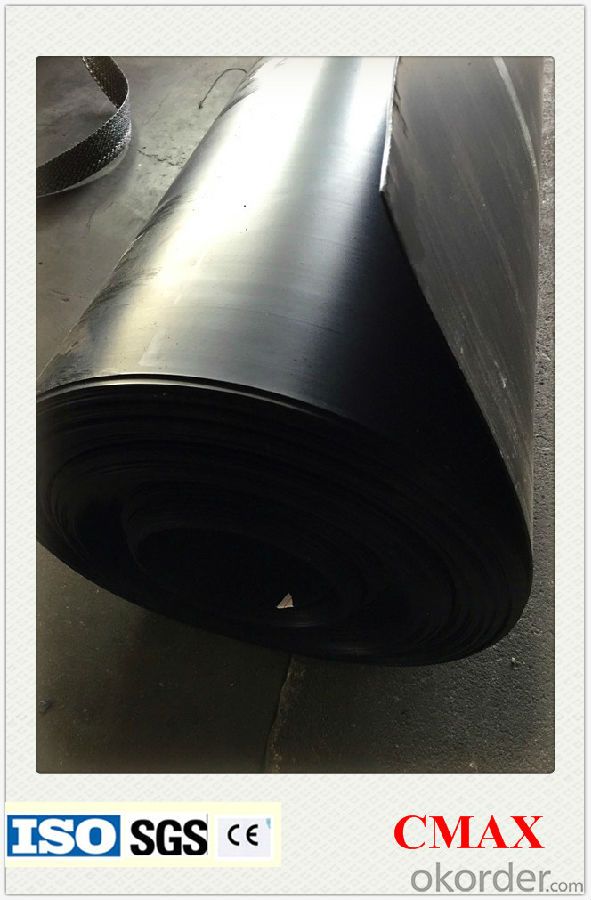

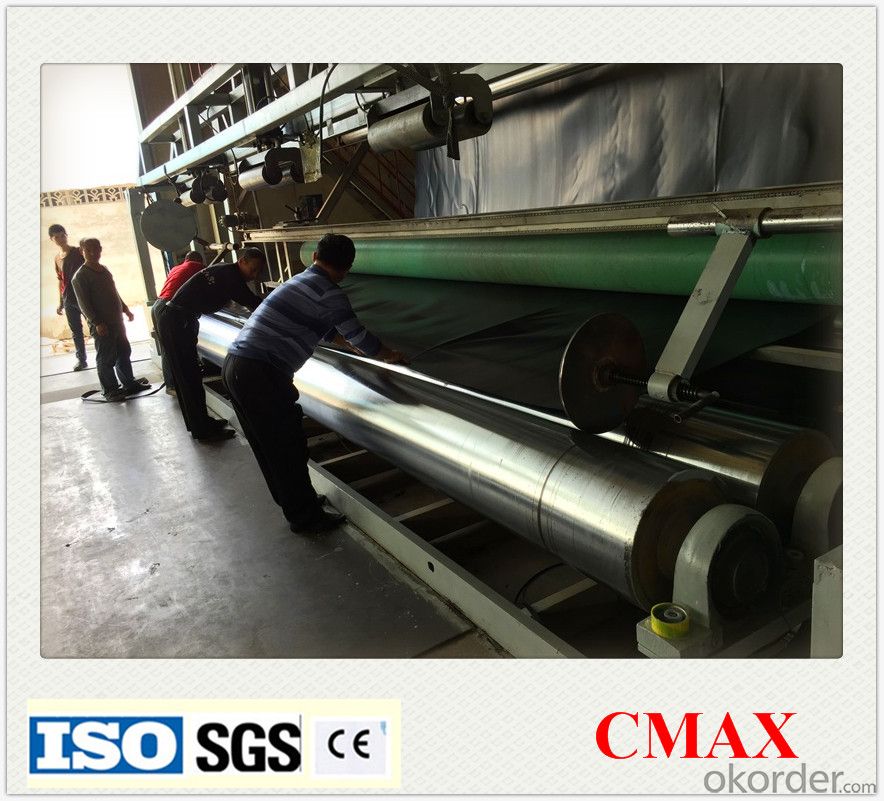

Geomembrane is made from LDPE, LLDPE, HDPE, EVA resin and additives such as antioxidant, carbon black, master batch etc with the method of 1 layer extrusion and 3 layers co-extrusion in high temperature.

Specification

1. Thickness: 0.1mm-3.0mm

2. 4m-9m in roll width, the length as clients' request.

Property:

Excellent waterproof, heat preservation, easy for welding, chemical and UV resistance.

Application:

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

5.Dike,the front of the sam foundation seepage prevention bedding,level of vertical impervious layer , construction cofferdam,waste field.

6.Seawater,freshwater fish farms.

7.Highway,the foundations of the highway and railway;the expansive soil and collapsible loess of the waterproof layer.

8.Anti-seepage of roofing

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 sqm.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Is black HDPE geomembrane eco-friendly?

- Raw material of HDPE geomembrane is HDPE particles, adding carbon?black to become black. It is buried underground to prevent hazardous liquid leakage. So HDPE geomembrane can be considered as environmentally friendly.

- Q: Can geomembranes be used in reservoir lining?

- Yes, geomembranes can be used in reservoir lining. Geomembranes are impermeable synthetic materials that can effectively prevent water seepage and provide a protective barrier in reservoirs. They are often used to line reservoirs to ensure water containment and prevent contamination.

- Q: Which is better for ceramic film and organic film ?

- Personally think that the ceramic membrane and ceramic membrane is an inorganic oxide sintering and into, and organic film is organic and ceramic membrane can be use in the high temperature, strong acid and alkali and organic solvents, the high cost of ceramic membrane, the use of long life. Organic film unit area.

- Q: What are the installation requirements for geomembranes in landfill liners?

- The installation requirements for geomembranes in landfill liners typically involve several key steps. First, the site must be properly prepared by removing any vegetation, debris, and loose soil. Next, a geotextile fabric is placed over the prepared subgrade to act as a cushion and protect the geomembrane. The geomembrane itself is then unrolled and positioned on top of the geotextile fabric, with sufficient overlap and tension to ensure a watertight seal. To secure the geomembrane, anchor trenches or batten strips are used around the perimeter, and ballast or soil cover is applied on top to protect it from wind and UV exposure. Finally, quality control tests such as spark testing or vacuum testing are conducted to ensure the integrity of the liner system. Overall, the installation of geomembranes in landfill liners requires careful planning, proper subgrade preparation, attention to detail, and adherence to industry standards and guidelines.

- Q: How do geomembranes prevent liquid evaporation in floating covers?

- Geomembranes prevent liquid evaporation in floating covers by acting as a barrier between the liquid and the atmosphere. They are impermeable to liquids and gases, effectively sealing the liquid underneath and preventing evaporation. Additionally, their high tensile strength and durability ensure that there are no leaks or gaps through which the liquid can escape.

- Q: Can geomembranes be used for decorative purposes?

- No, geomembranes are primarily used for functional purposes such as lining ponds, landfills, or containment areas, and are not typically used for decorative purposes.

- Q: How do geomembranes contribute to the prevention of soil subsidence?

- Geomembranes contribute to the prevention of soil subsidence by acting as a barrier between the underlying soil and any external forces that could cause it to sink or settle. They provide a stable and impermeable layer that helps to distribute loads evenly and prevent excessive water infiltration, thus reducing the risk of soil compaction and subsequent subsidence.

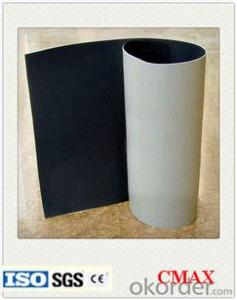

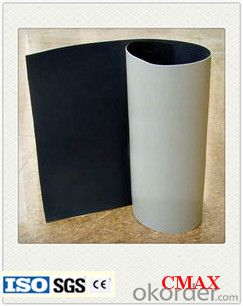

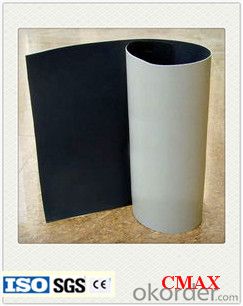

- Q: Does geomembrane has the color of grey?

- The color of the geomembrane is mostly black, and also green, white, gray, black green and other colors. The main material of geomembrane is high density polyethylene, auxiliary materials are antioxidants, anti UV agent, carbon black, masterbatch and so on, color of the geomembrane depending on the colour of added masterbatch. There is also geomembrane without auxiliary material, and it is transparent.

- Q: How do geomembranes contribute to the prevention of soil salinization?

- Geomembranes act as a barrier between the soil and external factors, preventing the infiltration of salts from nearby saline sources or irrigation water. By preventing saltwater intrusion, geomembranes help maintain the soil's natural salinity levels, thus contributing to the prevention of soil salinization.

- Q: Can PET film be used as thin film of the case sealing tape?

- It can not. PE tape is made from polyethylene and the film is soft and has low intensity, and it is commonly used in the field of protective film. PET tape, made from polyester and the film has high strength and good insulation performance, and it is commonly used in the insulation of electrical and electronic products.

Send your message to us

Geomembrana Hp 30 - LDPE/HDPE/LLDPE Geomembrane with Thickness 0.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords