GB Q235 Unequal Steel Angle

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Unequal Angle Steel:

1.Standards: JIS

2.Length: 6m,9m,12m

3.Material: SS400 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 100*75*7 | 9.32 | 100*75*10 | 13.0 |

| 100*75*8 | 10.6 | 100*75*12 | 15.4 |

| 100*75*9 | 11.8 |

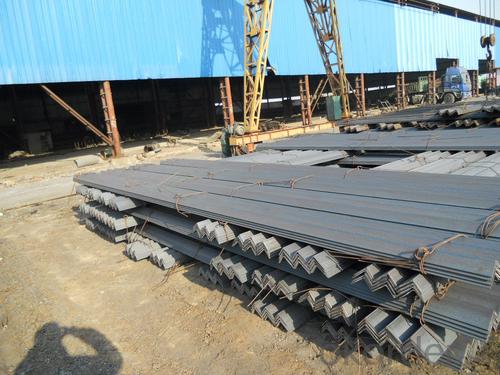

Packaging & Delivery of Unequal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel angles be used in mining or quarrying machinery?

- Steel angles are indeed applicable in mining or quarrying machinery. They offer structural support and reinforcement to different machinery components used in these sectors. Frames, supports, and brackets for equipment like crushers, conveyors, and screens are often constructed using steel angles. Due to their high strength and durability, steel angles can withstand the heavy loads, vibrations, and harsh operating conditions commonly experienced in mining or quarrying operations. Moreover, steel angles can be easily fabricated and welded to meet specific design needs, making them a flexible option for machinery applications in these industries.

- Q: What are the common industry standards for steel angles?

- The common industry standards for steel angles include various dimensions such as the length, width, and thickness of the angles, as well as tolerances, surface finishes, and mechanical properties. These standards are set by organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) to ensure consistency and quality in the production and use of steel angles across different industries.

- Q: Are steel angles resistant to pests and termites?

- Yes, steel angles are resistant to pests and termites as they are made of a material that pests cannot infest or damage.

- Q: Can steel angles be used for framing purposes?

- Yes, steel angles can be used for framing purposes. They are commonly used in construction for providing structural support and stability in framing applications, such as in the construction of buildings, bridges, and other structures. Steel angles offer strength and durability, making them an ideal choice for framing purposes.

- Q: Can steel angles be used for temporary structures or scaffolding?

- Yes, steel angles can be used for temporary structures or scaffolding. Steel angles provide strength, stability, and durability, making them suitable for supporting temporary structures and scaffolding systems. They are commonly used in construction projects due to their ability to withstand heavy loads and provide reliable support during temporary installations.

- Q: Can steel angles be used in the construction of schools?

- Yes, steel angles can be used in the construction of schools. Steel angles are versatile and commonly used in construction projects due to their strength and durability. They can be used for various purposes, such as framing, support beams, and reinforcement. Steel angles provide stability and structural integrity to the building, making them suitable for use in schools where safety and longevity are important factors. Additionally, steel angles are fire-resistant, which is crucial in ensuring the safety of students and staff. Overall, steel angles are a reliable and cost-effective choice for constructing schools.

- Q: How do you calculate the stability of a steel angle column?

- To calculate the stability of a steel angle column, a few key factors need to be considered. Firstly, the slenderness ratio of the column, which is the ratio of its effective length to its least radius of gyration, must be determined. This can be calculated using the formula: Slenderness ratio = (Effective length of column) / (Least radius of gyration) The least radius of gyration can be calculated using the dimensions of the angle section. For a steel angle, the least radius of gyration can be approximated as the average of the two legs of the angle section divided by the square root of 3. Once the slenderness ratio is determined, it is important to check whether the column is long or short. If the slenderness ratio is less than a critical value, typically around 50 for an angle column, it is considered short and the stability is primarily governed by its strength. In this case, the column can be designed based on its capacity to resist axial compression and flexural buckling. However, if the slenderness ratio exceeds the critical value, the column is considered long and its stability is primarily governed by its ability to resist lateral-torsional buckling. In such cases, additional calculations and considerations must be made to ensure the column's stability. For long angle columns, the critical load at which lateral-torsional buckling may occur can be calculated using various formulas and methods, such as the Euler formula, the Perry-Robertson formula, or finite element analysis. These calculations take into account various parameters such as the column's moment of inertia, modulus of elasticity, and the length of the column. It is important to note that stability calculations for steel angle columns can be complex and require expertise in structural engineering. It is recommended to consult with a qualified professional or refer to relevant design codes and standards, such as the American Institute of Steel Construction (AISC) Manual, for accurate and reliable calculations.

- Q: What are the different methods of surface preparation for painting steel angles?

- There are several methods of surface preparation for painting steel angles, each of which have their own benefits and considerations. 1. Manual cleaning: This method involves using hand tools such as wire brushes, sandpaper, or scrapers to remove loose rust, mill scale, and other contaminants. While it is a cost-effective option, it may not be suitable for large-scale projects or areas that are difficult to access. 2. Power tool cleaning: Power tools like grinders, sanders, or wire wheels can be used to mechanically remove rust, scale, and old paint from the surface of steel angles. This method is more efficient than manual cleaning and can be used in larger projects, but proper safety precautions and protective gear should be used. 3. Chemical cleaning: Chemical cleaning involves using solvents or acidic solutions to dissolve rust and remove contaminants from the steel surface. This method is effective for heavily corroded or hard-to-reach areas, but it requires careful handling and disposal of the chemicals. 4. Abrasive blasting: Abrasive blasting, also known as sandblasting, uses compressed air to propel abrasive materials such as sand, grit, or glass beads onto the surface of steel angles. This method is highly effective in removing all types of contaminants, providing a clean and rough surface for paint adhesion. However, it requires specialized equipment and should be conducted by trained professionals due to potential health hazards. Regardless of the method chosen, it is essential to ensure that the steel angles are thoroughly cleaned and free from contaminants before painting. This will help to achieve better paint adhesion, prolong the lifespan of the coating, and enhance the overall durability of the steel structure.

- Q: Can steel angles be used in fencing?

- Indeed, fencing can make use of steel angles. Steel angles find frequent application in fencing scenarios, serving to furnish structural reinforcement and stability. Their utility ranges from functioning as posts to serving as crossbars, contingent upon the particular design of the fencing. Steel angles possess robustness and durability, rendering them well-suited for enduring various elements whilst guaranteeing security. Through facile welding or bolting, steel angles can effortlessly be conjoined to construct a resilient fencing structure. Furthermore, steel angles can be galvanized or coated, augmenting their resistance to rust and corrosion, thereby securing a fencing solution that endures for a prolonged period with minimal maintenance.

- Q: Can steel angles be used in the construction of solar panel support structures?

- Yes, steel angles can be used in the construction of solar panel support structures. Steel angles provide structural support and stability, making them suitable for holding solar panels in place and withstanding various weather conditions.

Send your message to us

GB Q235 Unequal Steel Angle

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords