Hot Rolled Steel Equal Angle Bar Q235

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

.

Product Advantages:

OKorder's Angle Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

:

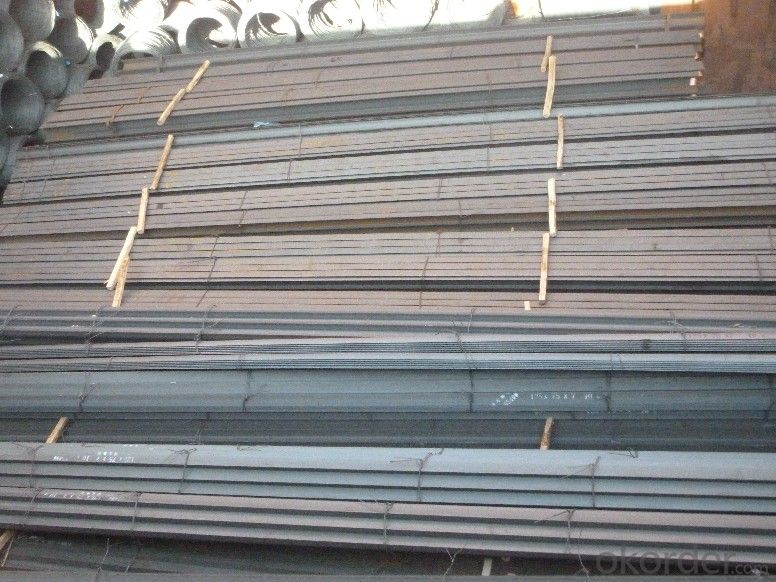

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Can steel angles be used in the construction of bridges?

- Yes, steel angles can be used in the construction of bridges. Steel angles are commonly used as structural components in bridge construction due to their strength, durability, and versatility. They can be used for various purposes such as supporting beams, bracing, or connecting different sections of the bridge. Steel angles provide stability, load-bearing capacity, and resistance to heavy loads, making them a suitable choice for bridge construction.

- Q: What are the different types of steel angles used in structural engineering?

- Steel angles are commonly utilized in structural engineering for their versatility and strength. They are available in various shapes and sizes, typically made from carbon steel or stainless steel, to suit specific structural applications. The following are some of the types of steel angles frequently used in this field: 1. L-Shaped Angles: These angles, also known as equal leg angles, have equal dimensions for both legs, resulting in a 90-degree angle. They are commonly employed as structural components in building frames, supports, and bracing systems. 2. Unequal Leg Angles: Unlike equal leg angles, these angles have differing lengths for each leg, resulting in an unequal angle. They are often used when a larger load-bearing capacity or specific structural requirements are necessary. 3. Angle Iron: Angle iron is a broad term encompassing various steel angles that have been rolled into a 90-degree angle. It is frequently used as a structural element in construction projects, such as framing, bracing, and supports. 4. Slotted Angles: Slotted angles are a variation of angle iron that feature holes or slots along the length of the angle. These holes allow for flexibility in attaching other structural components or accessories, making them versatile for shelving, racks, and workbenches. 5. Stainless Steel Angles: Stainless steel angles are fabricated from corrosion-resistant stainless steel alloys. They are commonly employed in applications where strength, durability, and resistance to corrosion are crucial, such as in the marine, food processing, and chemical industries. 6. Rolled Steel Angles: Rolled steel angles are produced by rolling steel plates or sheets to form an angled shape. They are widely used in construction projects due to their high strength-to-weight ratio and cost-effectiveness. 7. Structural Steel Angles: Structural steel angles are specifically designed for structural applications, such as supporting beams, columns, and trusses. They are typically manufactured from high-strength carbon steel and are available in various sizes and thicknesses to meet specific load-bearing requirements. In conclusion, the diverse range of steel angles used in structural engineering offers engineers numerous options to design and construct robust and efficient structures. The selection of the appropriate angle depends on factors such as load requirements, structural design, and environmental conditions.

- Q: What are the different types of steel angle connections?

- There are several different types of steel angle connections, including bolted connections, welded connections, and hybrid connections. Bolted connections involve using bolts and nuts to connect steel angles together. Welded connections involve melting the steel angles together using heat and a welding process. Hybrid connections combine elements of both bolted and welded connections, using a combination of bolts and welding to secure the steel angles together.

- Q: Can steel angles be used in high-rise buildings?

- Yes, steel angles can be used in high-rise buildings. Steel angles are commonly used as structural elements in building construction due to their strength and versatility. They can be used for various purposes such as supporting beams and columns, providing stability, and reinforcing connections in high-rise buildings.

- Q: How do steel angles perform in high-pressure applications?

- Steel angles are widely used in high-pressure applications due to their excellent performance under extreme conditions. The structural design and composition of steel angles provide them with exceptional strength and durability, making them capable of withstanding high pressure without deformation or failure. The unique shape of steel angles, with their L-shaped cross-section, enhances their load-bearing capacity and resistance to bending. This makes them ideal for applications where high-pressure forces are exerted, such as in the construction of pressure vessels, pipelines, and hydraulic systems. Steel angles are typically manufactured from high-strength carbon steel, which possesses inherent toughness and resilience. This material composition enables steel angles to maintain their structural integrity even when subjected to the intense forces associated with high-pressure environments. Furthermore, the versatility of steel angles allows for customization and adaptation to specific needs. They can be fabricated in different sizes, thicknesses, and lengths to accommodate varying pressure requirements. This flexibility ensures that steel angles can be tailored to specific applications, further enhancing their performance in high-pressure scenarios. In addition to their mechanical properties, steel angles also exhibit excellent corrosion resistance. This is crucial in high-pressure applications, as the presence of corrosive substances can deteriorate the structural integrity of components. The inherent corrosion resistance of steel angles prevents degradation over time, ensuring their long-term reliability and performance. Overall, steel angles are highly reliable and effective in high-pressure applications. Their exceptional strength, versatility, and corrosion resistance make them a preferred choice in industries where pressure containment is critical. By utilizing steel angles, operators can trust that their systems will perform reliably and safely under extreme pressure conditions.

- Q: How do you calculate the bending capacity of a steel angle?

- In order to determine the bending capacity of a steel angle, several factors must be considered. The initial step involves calculating the moment of inertia (I) of the angle section, which measures its resistance to bending. The moment of inertia relies on the angle's shape and dimensions, and can be found in the manufacturer's specifications or through calculations. Once the moment of inertia has been obtained, the section modulus (Z) can be calculated as another indicator of the section's ability to resist bending. The section modulus is found by dividing the moment of inertia by the distance from the centroid of the section to the extreme fiber. Subsequently, it is necessary to establish the maximum allowable bending stress (σ) for the steel angle. This value is typically provided by the manufacturer or can be determined based on the desired safety factor and the type of steel being used. Lastly, the bending capacity (M) of the steel angle can be calculated by utilizing the formula M = σ * Z. This calculation provides the maximum moment that the angle can endure without experiencing excessive bending stress. It is important to note that these calculations assume the angle's behavior is elastic and do not account for additional factors such as local buckling, residual stresses, or combined loading. Therefore, it is advisable to consult relevant design codes or guidelines for a more comprehensive analysis to ensure the safety and reliability of the steel angle in a specific application.

- Q: How do you reinforce a steel angle for added strength?

- There are various ways to reinforce a steel angle for added strength. One effective technique involves welding additional steel plates or gussets to the flanges of the angle. These plates or gussets are typically placed perpendicular to the angle and welded along their edges to create a stronger connection. This helps distribute the load and improve the structural integrity of the angle. Another approach is to create a sandwich-like structure by bolting or riveting additional steel plates or angles to the existing one. These additional elements can be positioned on either side or even on top of the existing angle, depending on the specific requirements. Bolting or riveting them together ensures a secure connection and enhances the overall strength of the angle. Furthermore, bracing techniques can also be employed to reinforce a steel angle. This involves adding diagonal steel members, commonly known as braces, to the angle. The braces are typically attached to the angle at multiple points using welding or bolting methods. By doing so, these braces help redistribute the forces acting on the angle and prevent excessive deflection or bending, thereby increasing its strength. It's important to consider factors such as the load or force the angle will experience, the desired level of strength, and the available resources when choosing a specific reinforcement method. Seeking guidance from a structural engineer or a professional in the field is highly recommended to ensure the appropriate reinforcement technique is chosen and implemented correctly.

- Q: How do you calculate the buckling capacity of a steel angle?

- To calculate the buckling capacity of a steel angle, you need to consider several factors. Firstly, determine the effective length of the angle. This is the distance between points of rotation or points of restraint. Next, calculate the slenderness ratio, which is the effective length divided by the radius of gyration. The radius of gyration is a measure of how the steel angle's cross-sectional area is distributed around its centroid. Once you have the slenderness ratio, you can refer to design codes or standards, such as the American Institute of Steel Construction (AISC) Manual, to find the critical buckling stress or load for the given slenderness ratio. These codes provide tables or formulas to determine the critical buckling capacity based on the angle's dimensions and material properties. It is important to note that the buckling capacity of a steel angle depends on the boundary conditions, end fixity, and the method of buckling, whether it is flexural or torsional. Therefore, understanding the specific loading and boundary conditions is crucial in accurately calculating the buckling capacity.

- Q: Are steel angles resistant to termites and pests?

- No, steel angles are not susceptible to termite and pest infestations as they are made of inorganic materials.

- Q: Can steel angles be cut to custom lengths?

- Yes, steel angles can be cut to custom lengths. Steel angles, also known as angle irons, are versatile structural components commonly used in construction and manufacturing. They are available in various standard sizes, but they can also be customized to meet specific length requirements. This can be achieved by using cutting tools such as saws or shears to trim the steel angle to the desired length. The ability to cut steel angles to custom lengths makes them suitable for a wide range of applications, as they can be tailored to fit specific design needs.

Send your message to us

Hot Rolled Steel Equal Angle Bar Q235

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords