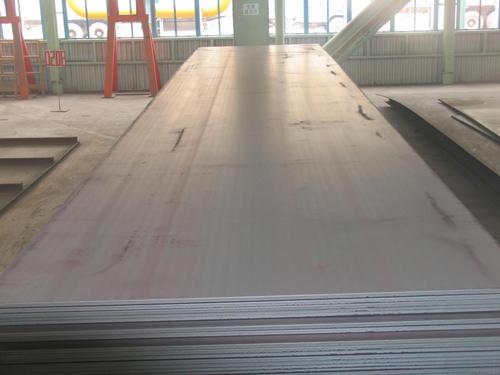

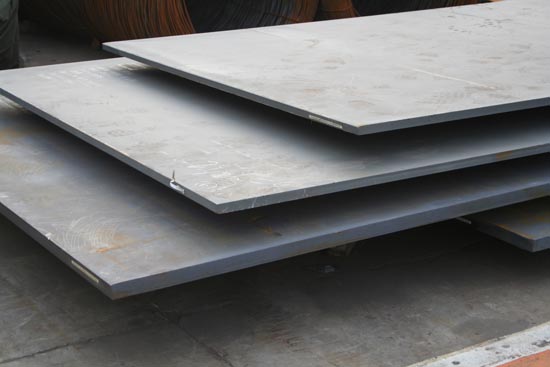

Prime Q235 Hot Rolled Steel Sheets S235JR Q235

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Steel Sheets

Application: Floor board, factory stair boards, deck board, car boards ,staircases, lorry beds, elevator floors, general fabrication.

Material: Q195 Q225 Q235 Q345 A36 S235jr St37-2 SS400 and so on

Uses: Fridge ,air conditioner, washing machine and household appliances, automobile,steel furniture, drum, motorcycles, fitting apparatuses, furniturem,builings electronic telecoms and gas- conveyance projects.

Product: | Hot Rolled Steel Sheets |

Material: | Q195,Q235,A36,SS400,S235JR,Q345,ST37-2, CCSB etc |

Standard : | JIS G3002 GB/T251B |

Thickness | 1.20-25.0mm |

Width: | 1000mm-2000mm |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm, 1250mm, 1500mm |

Length: | 0-18000mm |

Coil Weight: | 10-25 Metric Tons |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

- Q: Can steel sheets be used for manufacturing shipping pallets?

- Yes, steel sheets can be used for manufacturing shipping pallets. Steel is a strong and durable material that can withstand heavy loads, making it suitable for the construction of pallets. Steel sheets can be welded or bolted together to create a sturdy and reliable pallet structure. Additionally, steel pallets have the advantage of being resistant to moisture, pests, and fire, which can be important considerations for certain industries or applications. However, it is worth noting that steel pallets are generally more expensive than other materials such as wood or plastic, so the choice of using steel sheets for manufacturing shipping pallets would depend on specific requirements, budget, and intended use.

- Q: What are the different surface gloss levels available for steel sheets?

- The different surface gloss levels available for steel sheets include matte, satin, semi-gloss, and high gloss.

- Q: Are steel sheets corrosion-resistant?

- Yes, steel sheets can be corrosion-resistant depending on their composition and treatment. Stainless steel, for example, is known for its excellent corrosion resistance due to its high chromium content. This chromium forms a protective oxide layer on the surface that prevents further corrosion. Galvanized steel sheets are also corrosion-resistant as they are coated with a layer of zinc that acts as a barrier against corrosion. However, it is important to note that the corrosion resistance of steel can vary depending on factors such as the environment, exposure to chemicals, and maintenance. Regular inspection and maintenance are necessary to ensure the long-term corrosion resistance of steel sheets.

- Q: How is the weight of the steel plate calculated?

- Steel plate by thickness, thin steel plate <4 mm (thinnest 0.2 mm), thick steel plate 4~60 mm, extra thick steel plate 60~115 mm.The steel plate is divided into hot-rolled and cold-rolled parts according to rolling.The width of the sheet is 500~1500 mm; the thickness is 600~3000 mm. According to the type of steel sheet, ordinary steel, stainless steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel and industrial pure iron sheet; according to professional use, with drums board, enamel board, bulletproof plate; surface coating and plating, plating with zinc thin plate, tin plate, plating lead sheet, plastic composite plate.

- Q: Can steel sheets be used for making furniture?

- Yes, steel sheets can be used for making furniture. Steel is a versatile material that offers several advantages when used for furniture construction. It is known for its strength, durability, and ability to withstand heavy loads. Steel sheets can be shaped, welded, and fabricated into various furniture pieces such as tables, chairs, cabinets, and even bed frames. Additionally, steel furniture tends to be resistant to rust and corrosion, making it suitable for both indoor and outdoor use. The sleek and modern aesthetic of steel also adds a contemporary touch to any space.

- Q: Can steel sheets be used for elevator interiors?

- Yes, steel sheets can be used for elevator interiors. Steel is a durable and versatile material that can withstand high levels of traffic and wear. It can be easily customized, painted, or textured to create an aesthetically pleasing interior design for elevators. Additionally, steel sheets offer excellent resistance to fire and moisture, making them a suitable choice for elevator interiors.

- Q: What are the different thickness options for steel sheets?

- The thickness options for steel sheets vary depending on the specific application and industry requirements. Common thickness options for steel sheets range from thin gauges, such as 26 gauge (0.0179 inches) or 30 gauge (0.0120 inches), to thicker gauges, such as 16 gauge (0.0598 inches) or 10 gauge (0.1345 inches). However, it is important to note that steel sheets can be customized to meet specific thickness requirements beyond these standard options.

- Q: What are the common thicknesses for roofing steel sheets?

- The common thicknesses for roofing steel sheets range from 22 gauge (0.0299 inches) to 29 gauge (0.0149 inches), with 26 gauge (0.0187 inches) being the most commonly used thickness in the industry.

- Q: How do steel sheets perform under heavy loads or pressure?

- Steel sheets are known for their exceptional strength and durability, making them highly resistant to heavy loads or pressure. Due to their composition and manufacturing process, steel sheets possess a high tensile strength, which allows them to withstand substantial amounts of force without deforming or breaking. This property makes steel sheets ideal for applications where heavy loads or pressure are involved, such as construction, transportation, and industrial machinery. Additionally, steel sheets have excellent load-bearing capacity, meaning they can distribute the applied pressure evenly across their surface, minimizing the risk of structural failure or damage. The ability of steel sheets to perform under heavy loads or pressure is further enhanced by their rigidity, which prevents them from bending or buckling, ensuring the integrity of the structure or equipment they are supporting. Overall, steel sheets are a reliable and robust choice when it comes to handling heavy loads or pressure, making them a popular material in various industries.

- Q: Are steel sheets resistant to discoloration from sunlight?

- Yes, steel sheets are generally resistant to discoloration from sunlight.

Send your message to us

Prime Q235 Hot Rolled Steel Sheets S235JR Q235

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords