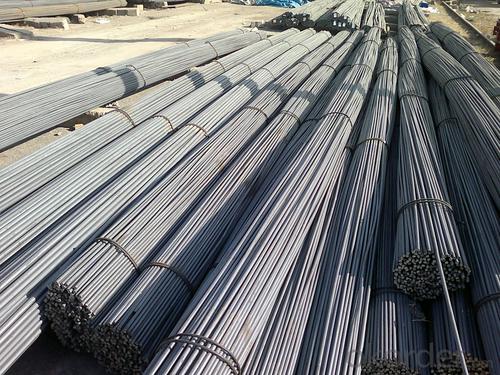

Hot Rolled GB Standard Round Steel Bar Q235, SAE1020

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled GB Standard Round Steel Bar Q235, SAE1020 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled GB Standard Round Steel Bar Q235, SAE1020 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries. Carbon steel round bar is the most common form of steel because its price is relatively low while it provides material properties that are acceptable for many applications, more so than iron. It is often used when large quantities of steel are needed, for example as structural steel. The density of this product is approximately 7.85g/cm³ and the young's modulus, like all steels.

Product Advantages:

OKorder's Hot Rolled GB Standard Round Steel Bar Q235, SAE1020 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications of Hot Rolled GB Standard Round Steel Bar Q235, SAE1020

1. Grade: Q235, SS400, S235JR, A36

2. Sizes: Diameter: 6mm-150mm; Length: 6m, 9m, 12m or as customer’s request

3. Type: Mild steel; Low carbon steel

4. Shape: Round bar, solid bar of steel with circular section

5. Technique: Hot rolled or cold drawn

6. Mass: Mass(kg/m) = Diameter(mm)×Diameter(mm)×0.00617

Steel Type | Maximum forging temperature (°F / °C) | Burning temperature (°F / °C) |

1.5% carbon | 1920 / 1049 | 2080 / 1138 |

1.1% carbon | 1980 / 1082 | 2140 / 1171 |

0.9% carbon | 2050 / 1121 | 2230 / 1221 |

0.5% carbon | 2280 / 1249 | 2460 / 1349 |

0.2% carbon | 2410 / 1321 | 2680 / 1471 |

3.0% nickel steel | 2280 / 1249 | 2500 / 1371 |

3.0% nickel–chromium steel | 2280 / 1249 | 2500 / 1371 |

5.0% nickel (case-hardening) steel | 2320 / 1271 | 2640 / 1449 |

Packaging & Delivery of Hot Rolled GB Standard Round Steel Bar Q235, SAE1020

Packaging Detail: All goods are packed in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: 45 days

Trade terms: FOB, CFR, CIF

MOQ: 25 tons per specification; we can negotiate the quantity if the specification is normal or we have stock of one specification.

Weight: The price invoicing on theoretical weight basis or actual weight basis depends on customer’s request.

Shipment: The shipment of bulk break or container is depends on customer’s request and the situation of the port of destination.

Documents given: Full set of original clean on board bill of lading; Original signed commercial invoice; Original packing list; Policy of insurance; Certificate of origin and what the target market needs.

Production Flow of Hot Rolled GB Standard Round Steel Bar Q235, SAE1020

1. The common processes are preheated forging quenching, dual refinement solution process, cooling quenching and isothermal quenching. We use heat treatment for dual refinement solution process. The main measures process is high temperature solution and refinement cycle. High temperature solution can improve the carbide morphology and particle size. The aim is to make the loop refinement ultrafine austenite grains.

2. EAF+LF+VD+ Forged+ Heat Treatment

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Can fit in the containers of 20fts the steel beams of 6M?

A3: No proble, we can put them into the containers in the form sideling.

- Q: Can steel round bars be used in the production of construction materials?

- Indeed, the utilization of steel round bars is feasible in the manufacturing of construction materials. Owing to their remarkable robustness and endurance, steel round bars find frequent application within the construction sector. These bars are instrumental in fortifying concrete structures, exemplified by the reinforcement of beams, columns, and slabs, thereby enhancing their resilience and steadfastness. Furthermore, in the construction of buildings and bridges, steel round bars can be employed in the creation of steel frames, trusses, and various structural constituents. The widespread popularity of these bars stems from their adaptability and capacity to endure substantial burdens in the construction industry.

- Q: What are the different types of steel round bar alloys used in the aerospace industry?

- There are several different types of steel round bar alloys used in the aerospace industry, including stainless steel, titanium alloy, nickel alloy, and carbon steel. These alloys offer specific properties such as high strength, corrosion resistance, and heat resistance, making them suitable for various applications in aircraft manufacturing.

- Q: What are the different types of steel round bar finishes?

- There are several different types of steel round bar finishes, including hot rolled, cold drawn, turned and polished, and ground and polished.

- Q: What are the different types of steel round bars used in the automotive braking systems?

- Automotive braking systems rely on various types of steel round bars that possess specific properties for optimal performance. These steel variants are carefully selected for their strength, durability, and ability to withstand the intense temperatures and pressures that arise during braking. One commonly utilized steel round bar is carbon steel, renowned for its exceptional hardness and high strength. Brake rotors and drums often incorporate carbon steel round bars due to their ability to endure the heat and friction generated during braking, ensuring reliable and long-lasting performance. Stainless steel represents another steel round bar employed in automotive braking systems. Its resistance to corrosion and rust make it an ideal choice for brake lines and fittings. Additionally, stainless steel boasts excellent heat resistance properties, enabling it to endure the thermal stresses generated during braking. Furthermore, alloy steel round bars find application in automotive braking systems. Combining various metals like chromium, nickel, and molybdenum, alloy steel enhances its mechanical properties. Known for their remarkable tensile strength and toughness, alloy steel round bars suit demanding applications that require superior performance and durability. Specialized types of steel round bars also exist, designed specifically for particular applications within automotive braking systems. For instance, heat-treated steel round bars are employed in the manufacturing of brake calipers and pistons due to their capability to withstand the extreme temperatures resulting from the friction between brake pads and rotors. In summary, the selection of steel round bars in automotive braking systems hinges upon specific requirements, encompassing strength, durability, heat resistance, and corrosion resistance. By carefully choosing the appropriate steel variant, automotive manufacturers can guarantee the safety and reliability of their braking systems.

- Q: How can steel round bars be protected against corrosion?

- Steel round bars can be protected against corrosion through various methods such as applying a protective coating, galvanizing, using corrosion inhibitors, or implementing cathodic protection. These techniques form a barrier between the steel surface and corrosive elements, preventing or slowing down the process of corrosion.

- Q: What are the different surface treatments available for carbon steel round bars?

- Carbon steel round bars have various surface treatments available, each serving a specific purpose and offering unique advantages. Some of the most commonly used treatments include: 1. Galvanizing: A layer of zinc is applied to the surface of the carbon steel round bar. This treatment provides exceptional corrosion resistance and significantly prolongs the steel's lifespan. 2. Black oxide coating: Also called blackening, this treatment creates a uniform, dark finish on the surface of the carbon steel round bar. Black oxide coatings offer mild corrosion resistance, improved lubricity, and a decorative appearance. 3. Chromium plating: By depositing a layer of chromium onto the carbon steel round bar's surface, typically through electroplating, this treatment enhances corrosion resistance, wear resistance, and provides a polished appearance. 4. Nitriding: Nitriding is a heat treatment process that diffuses nitrogen into the surface of the carbon steel round bar, resulting in a hard and wear-resistant layer. This treatment improves the steel's hardness and fatigue strength, making it suitable for applications requiring enhanced durability. 5. Phosphating: Phosphating is a chemical treatment that converts the surface of the carbon steel round bar into a layer of phosphate crystals. This treatment offers excellent corrosion resistance and enhances the adhesion of applied coatings or paints. 6. Powder coating: This treatment involves applying a dry powder to the surface of the carbon steel round bar, which is then cured under heat to form a protective coating. Powder coatings provide exceptional corrosion resistance, durability, and can be customized in various colors and finishes. These examples represent only a few of the available surface treatments for carbon steel round bars. The choice of treatment depends on the specific requirements of the application, such as corrosion resistance, wear resistance, aesthetics, and cost-effectiveness.

- Q: Are steel round bars suitable for machining operations?

- Yes, steel round bars are suitable for machining operations. Steel is known for its high strength and durability, making it an excellent material for various machining processes. Steel round bars can be easily shaped, cut, drilled, and turned to create precise components or parts. Machining operations such as milling, drilling, and turning can be efficiently performed on steel round bars to achieve the desired shape, size, and finish. Additionally, steel round bars offer good dimensional stability and excellent mechanical properties, allowing for accurate and consistent machining results. Overall, steel round bars are a reliable choice for machining operations in various industries including automotive, aerospace, construction, and manufacturing.

- Q: How do steel round bars contribute to sustainable construction?

- Steel round bars contribute to sustainable construction in several ways. Firstly, steel is a highly durable and long-lasting material, which means that structures built using steel round bars have a longer lifespan and require less maintenance and repairs over time. This reduces the need for frequent replacement, thereby conserving resources and reducing waste. Secondly, steel is a recyclable material, and steel round bars can be easily recycled and reused in other construction projects. By promoting the use of recycled steel, we can reduce the demand for raw materials and minimize the environmental impact associated with steel production. Additionally, steel round bars offer excellent structural strength and flexibility, allowing for more efficient designs and optimized use of materials. This results in lighter and more sustainable structures that require fewer resources to construct. Lastly, steel round bars are often used in reinforced concrete structures, which can enhance the durability and seismic resistance of buildings. By utilizing steel reinforcement, we can ensure the longevity and safety of structures, reducing the need for reconstruction and enhancing the resilience of our built environment. Overall, steel round bars contribute to sustainable construction by promoting durability, recyclability, resource efficiency, and improved structural performance in buildings and infrastructure projects.

- Q: What are the typical price ranges for steel round bars?

- The typical price ranges for steel round bars can vary depending on various factors such as the type of steel, the diameter, length, and the quantity being purchased. Generally, steel round bars can range in price from $1 to $5 per foot for common carbon steel grades. However, specialty and high-grade steel round bars can be priced higher, ranging from $5 to $20 per foot or even more. Additionally, larger diameter or longer length steel round bars may also be priced higher due to increased material and manufacturing costs. It is important to note that these price ranges are approximate and can vary based on market conditions, supplier pricing, and other factors. To get an accurate price range, it is recommended to contact steel suppliers or distributors for specific quotes based on your requirements.

- Q: Can steel round bars be used in the manufacturing of bicycles?

- Yes, steel round bars can be used in the manufacturing of bicycles. Steel is a commonly used material in bicycle manufacturing due to its strength, durability, and affordability. Steel round bars can be shaped, welded, and manipulated to form the frame, handlebars, and other components of a bicycle.

Send your message to us

Hot Rolled GB Standard Round Steel Bar Q235, SAE1020

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords