Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

OKorder is offeringUnequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

OKorder's Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled are durable, strong, and resist corrosion.

Main Product Features of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

Hot Rolled Steel Unequal Angles

1. Shape:Unequal

2. Standard:ASTM,BS,DIN,GB,JIS

3.Grade:Q195,Q235,Q345,SS400,A36,ST37

May we help you to optimize your products sourcing? | |

1. Strategic location: Our factory is located in the famous steel town of Shengfang. | |

2. Industrial product expertise | |

3. Product reliability, competitive price, and on-time delivery | |

4. Unparalleled service and reliability | |

5. Business philosophy: Credit First, Be Honesty, Mutual Benefit and Customer Supremacy. | |

Detail information: | |

Type | Equal & Unequal |

Thickness Tolerance | +/- 8% |

Packing | export standard packing(bundles, seaworthy package, shipped in container) |

Delivery Port | Tianjin, China |

Lead Time | within 30days after received the original L/C or deposit |

MOQ | 10 Tons per size |

Certificate | SGS Certificate if needed; the cost of inspection for buyer. |

Usage | Construction, communications steel tower, civil or agricultural machine making |

Production Capacity | 5,000MT per month |

Main Market | Europe, America, Africa, Southeast |

Welcome every old and new clients to come to negotiate and telecommunicate with us | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

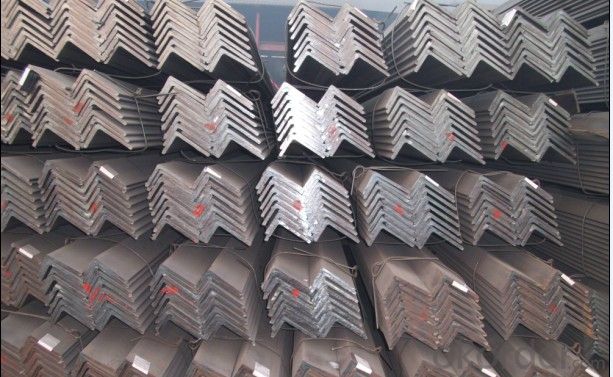

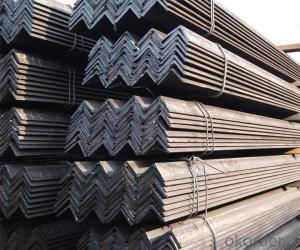

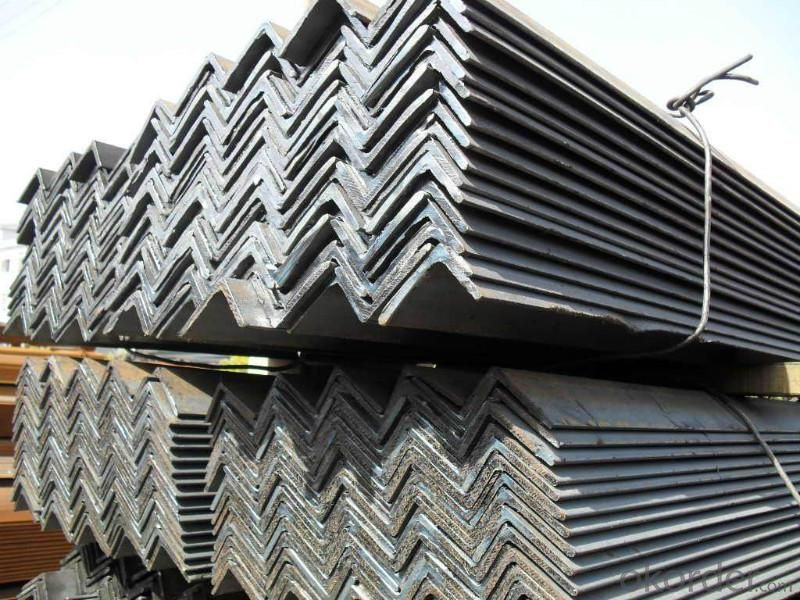

Images of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

- Q: Can steel angles be used for pipe supports or hangers?

- Yes, steel angles can be used for pipe supports or hangers. Steel angles provide structural support and stability, making them suitable for holding and securing pipes in various applications.

- Q: Can steel angles be used as supports for signage or lighting fixtures?

- Yes, steel angles can be used as supports for signage or lighting fixtures. Steel angles are commonly used in construction and can provide strong and sturdy support for various applications, including signage and lighting fixtures.

- Q: What are the different design considerations for steel angles in industrial buildings?

- Some of the key design considerations for steel angles in industrial buildings include the load-bearing capacity of the angles, the overall structural stability, the desired level of durability and resistance to corrosion, and the aesthetic appearance of the angles. Additionally, factors such as the specific application and function of the angles, the environmental conditions, and the available budget also play a role in determining the design considerations for steel angles in industrial buildings.

- Q: What are the different surface finishes for steel angles?

- Steel angles can be given various surface finishes to meet different aesthetic and functional requirements. Some commonly used finishes for steel angles include: 1. Mill Finish: Obtained straight from the mill without any treatment, this finish has a rough and dull appearance with visible imperfections and mill scale. 2. Hot-dip Galvanized: The steel angle is immersed in molten zinc, creating a protective coating that offers excellent corrosion resistance, ideal for outdoor and marine applications. 3. Powder Coated: A dry powder is applied to the steel angle and then cured with heat, resulting in a durable and smooth finish. This finish provides a wide range of color options and offers good corrosion resistance and aesthetics. 4. Painted: Different types of paint, such as enamel, epoxy, or acrylic, can be used to enhance the appearance of steel angles and provide some level of corrosion protection. 5. Stainless Steel: Steel angles made from stainless steel have a natural corrosion-resistant surface finish. They are commonly available in brushed or polished finishes, giving a clean and shiny appearance. 6. Galvannealed: This specialized finish involves galvanizing the steel angle and then heat treating it to create a matte, grayish finish. Galvannealed finish offers good corrosion resistance and paint adhesion, making it suitable for applications that require both. These are just a few examples of the available surface finishes for steel angles. The choice of finish will depend on factors such as the intended use, environment, and desired appearance of the steel angle.

- Q: What is the typical ductility of steel angles?

- The typical ductility of steel angles varies depending on the specific grade of steel used and the manufacturing process. However, in general, steel angles are known to possess excellent ductility. Ductility refers to the ability of a material to deform under tensile stress without fracturing. Steel, including steel angles, is known for its high ductility, which allows it to be easily formed, bent, or twisted without breaking. This characteristic makes steel angles highly versatile and suitable for various applications, such as construction, engineering, and manufacturing.

- Q: What is a steel angle?

- A steel angle, also known as an angle iron or L-shaped bar, is a structural steel product that features two perpendicular legs joined together at a 90-degree angle. It is commonly used in construction and engineering applications as a support or reinforcement for various structures due to its strength and versatility. Steel angles are typically made from carbon steel or stainless steel and come in various dimensions, thicknesses, and lengths to suit different project requirements. They can be easily cut, welded, and bolted, making them a popular choice for framing, bracing, and supporting beams, columns, and other structural elements. Additionally, steel angles are also frequently utilized in the manufacturing of shelves, brackets, frames, and other metalwork applications.

- Q: How do steel angles perform in terms of impact resistance?

- Steel angles are known for their excellent impact resistance due to their structural properties and high tensile strength. They can effectively absorb and distribute the force from impacts, making them highly reliable in applications where impact resistance is crucial.

- Q: Can steel angles be used in seismic zones?

- Yes, steel angles can be used in seismic zones. Steel angles are commonly used in seismic design and construction as they provide structural support and stability. However, it is important to ensure that the steel angles are designed and installed according to the specific building codes and regulations for seismic zones to ensure their effectiveness and safety.

- Q: Can steel angles be used in high-temperature environments?

- Steel angles can be used in high-temperature environments, but their performance depends on the specific grade of steel being used. Some steel angles are specifically designed for high-temperature applications and can withstand extreme heat without significant distortion or structural failure. These high-temperature steel angles are typically made from alloys that have excellent heat resistance properties, such as stainless steel or nickel-based alloys. However, it is important to consider the operating temperature and duration of exposure when selecting steel angles for high-temperature environments. Prolonged exposure to high temperatures can still lead to some degradation of the material, including oxidation, reduction in mechanical properties, or even melting in extreme cases. To ensure the suitability of steel angles in high-temperature environments, it is recommended to consult with experts or engineers who have knowledge of the specific application and can provide guidance on selecting the appropriate grade of steel angle. Additionally, regular inspections and maintenance are crucial to identify any signs of degradation or wear caused by high temperatures.

- Q: Are steel angles resistant to pests or insects?

- Yes, steel angles are resistant to pests or insects as they are made of solid, non-organic material, which does not provide a suitable environment for pests or insects to thrive.

Send your message to us

Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches