Q235 Stainless high quality steel round bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Q235 Stainless high quality steel round bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Q235 Stainless high quality steel round bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Q235 Stainless high quality steel round bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

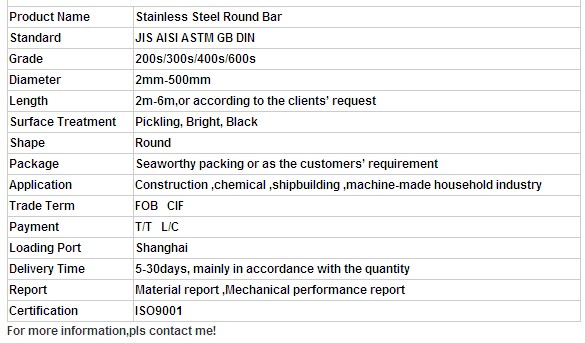

Product Specifications:

stainless steel round bar

1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: Are steel round bars suitable for use in the automotive industry?

- Yes, steel round bars are suitable for use in the automotive industry. Steel round bars offer several advantages that make them ideal for automotive applications. Firstly, steel round bars provide excellent strength and durability, which are crucial for automotive components that need to withstand high levels of stress and impact. The high tensile strength of steel ensures that these components can handle the demanding conditions of the automotive industry, such as heavy loads and harsh environments. Secondly, steel round bars have good machinability, allowing them to be easily shaped and fabricated into various automotive parts. This versatility is essential for creating components with complex geometries, such as crankshafts, axles, and suspension components. Furthermore, steel round bars offer superior dimensional stability, ensuring that automotive parts maintain their shape and performance over time. This is particularly important for critical components that need to meet precise specifications and tolerances. Additionally, steel round bars have excellent heat resistance, making them suitable for applications that involve high temperatures, such as engine components and exhaust systems. The thermal stability of steel ensures that these parts can operate efficiently and reliably under extreme heat conditions. Moreover, steel is readily available and cost-effective compared to other materials, making it an attractive choice for the automotive industry. The abundance of steel resources and the well-established manufacturing processes contribute to its affordability, making it a practical option for mass production. In conclusion, steel round bars are highly suitable for use in the automotive industry due to their strength, durability, machinability, dimensional stability, heat resistance, and cost-effectiveness. These qualities make steel round bars an excellent choice for various automotive components, contributing to the overall performance, safety, and longevity of vehicles.

- Q: What are the advantages of using wear-resistant steel round bars?

- The advantages of using wear-resistant steel round bars are that they provide increased durability, extended service life, and enhanced performance in high-wear applications. These bars are specifically designed to withstand abrasion, impact, and other forms of wear, making them ideal for industries such as mining, construction, and manufacturing. By using wear-resistant steel round bars, companies can reduce maintenance costs, minimize downtime, and improve overall operational efficiency.

- Q: What are the factors to consider when selecting a steel round bar for a specific application?

- When selecting a steel round bar for a specific application, there are several important factors to consider. 1. Material Grade: The first factor to consider is the material grade of the steel round bar. Different grades of steel have varying properties, such as strength, hardness, and corrosion resistance. It is crucial to choose a material grade that is suitable for the specific application's requirements. 2. Mechanical Properties: The mechanical properties of the steel round bar, such as tensile strength, yield strength, and elongation, need to be evaluated. These properties determine the bar's ability to withstand forces and deformations under load. The selected steel round bar should have mechanical properties that match the demands of the application. 3. Size and Dimensions: The size and dimensions of the steel round bar are crucial considerations. This includes the diameter, length, and tolerance requirements. The dimensions should be chosen based on the application's structural requirements and the intended load-bearing capacity of the bar. 4. Surface Finish: The surface finish of the steel round bar is significant, especially for applications involving aesthetics or contact with other components. Considerations such as smoothness, roughness, and the presence of any coatings or treatments should be taken into account. 5. Corrosion Resistance: Depending on the application's environment, it is essential to select a steel round bar with adequate corrosion resistance. Factors such as exposure to moisture, chemicals, or extreme temperatures can affect the bar's longevity and performance. Stainless steel or corrosion-resistant coatings can be chosen to enhance the bar's resistance to corrosion. 6. Machinability: If the steel round bar needs to be machined or fabricated into a specific shape, its machinability must be considered. Some steel grades are easier to machine, while others may require more advanced tools or techniques. The machinability of the selected bar should align with the desired manufacturing processes. 7. Cost: Finally, the cost of the steel round bar should be considered. Different material grades and specifications come with varying price points. It is important to balance the required properties and performance with the project's budget constraints. Overall, selecting a steel round bar for a specific application requires careful evaluation of the material grade, mechanical properties, size, surface finish, corrosion resistance, machinability, and cost. By considering these factors, one can ensure that the chosen steel round bar will meet the application's requirements and deliver optimal performance.

- Q: Can steel round bars be coated or plated?

- Steel round bars can indeed be coated or plated, which is a prevalent method employed to augment the functionality and visual appeal of steel products. Numerous choices exist for coating and plating, including zinc plating, chrome plating, nickel plating, and powder coating. These procedures offer added defense against corrosion, enhance durability, and create the desired aesthetics for the steel. The selection of the appropriate coating or plating technique hinges upon the particular application and specifications of the steel round bars.

- Q: What is the difference between a bright and a precision ground steel round bar?

- A bright steel round bar and a precision ground steel round bar are two different types of steel bars with distinct characteristics and manufacturing processes. The main difference between a bright steel round bar and a precision ground steel round bar lies in their surface finish and manufacturing tolerances. A bright steel round bar, also known as a bright mild steel bar or a bright mild steel round bar, undergoes a process called bright drawing. This process involves pulling the steel bar through a die to achieve a smooth and shiny surface finish. As a result, bright steel round bars have a highly polished appearance and a clean, smooth texture. They are commonly used in decorative applications, such as in the manufacturing of furniture, automotive accessories, and architectural elements. On the other hand, a precision ground steel round bar is manufactured with tight dimensional tolerances and precise surface finishes. These bars are typically made through the process of precision grinding, where the steel bar is machined to achieve a specific diameter and surface finish. Precision ground steel round bars are known for their accuracy and consistency in size, making them suitable for applications that require close tolerance and high precision, such as in the manufacturing of bearings, shafts, and hydraulic cylinders. In summary, the key difference between a bright steel round bar and a precision ground steel round bar lies in their surface finish and manufacturing tolerances. A bright steel bar has a polished appearance and is used primarily for decorative purposes, while a precision ground steel bar is machined to precise dimensions and is suitable for applications that require high precision and close tolerances.

- Q: What are the advantages of using nickel-molybdenum-vanadium alloy steel round bars?

- Nickel-molybdenum-vanadium alloy steel round bars offer several benefits due to their unique properties. Firstly, they possess remarkable strength and durability, making them suitable for applications that demand structural integrity. Industries such as construction, automotive, and aerospace can benefit from this alloy's ability to withstand heavy loads and resist deformation. Additionally, these round bars exhibit excellent resistance to corrosion. The inclusion of nickel and vanadium in the alloy enhances its oxidation and corrosion resistance, even in harsh environmental conditions. Therefore, it becomes a preferred choice for applications that involve exposure to moisture, chemicals, or corrosive substances. Moreover, nickel-molybdenum-vanadium alloy steel round bars possess high heat resistance, making them suitable for use in high-temperature applications. The presence of molybdenum in the alloy enhances its ability to withstand thermal stress, ensuring structural stability even at elevated temperatures. Industries such as oil and gas, power generation, and heat exchangers can benefit from this property. The versatility of these round bars is another advantage. They can be easily forged, machined, and welded, allowing for a wide range of manufacturing processes. This versatility makes them suitable for applications that require complex shapes and designs, such as shafts, gears, and valves. Despite their numerous advantages, nickel-molybdenum-vanadium alloy steel round bars are relatively cost-effective compared to other high-performance alloys. Their excellent combination of properties results in a longer lifespan, reduced maintenance requirements, and improved performance, leading to cost savings over time. In conclusion, the use of nickel-molybdenum-vanadium alloy steel round bars offers high strength and durability, corrosion resistance, heat resistance, versatility, and cost-effectiveness. These properties make them a preferred choice for various industries and applications.

- Q: What are the different types of steel round bar alloys for improved corrosion resistance?

- There are several different types of steel round bar alloys that offer improved corrosion resistance. Some common examples include stainless steel alloys such as 304, 316, and 410, which contain chromium and nickel to create a protective layer against corrosion. Additionally, weathering steel alloys like ASTM A588 and A709 are known for their ability to develop a rust-like appearance that acts as a protective barrier. Other options include duplex stainless steels, which combine the benefits of austenitic and ferritic alloys, and high-alloy steels like Inconel and Hastelloy, which are highly resistant to corrosion in extreme environments.

- Q: How are steel round bars made?

- Hot rolling is the method used to produce steel round bars. It starts by heating a large rectangular steel billet until it becomes malleable. Then, the heated billet is fed through a series of rolling stands that gradually decrease its thickness and give it a round shape. To begin the hot rolling process, the billet is placed in a furnace and subjected to extremely high temperatures, typically ranging from 1200 to 1300 degrees Celsius. This high heat makes the steel more pliable and easier to manipulate. Once the billet is heated, it is introduced into a rolling mill. This mill consists of rollers that progressively reduce the thickness and elongate the billet. Each set of rollers squeezes and stretches the billet, gradually forming it into a round shape. The number of passes through the rolling mill depends on the desired final size and shape of the round bar. While the rolling process takes place, the steel bar is also cooled to prevent overheating and ensure proper metallurgical properties. This cooling can be achieved through the use of a water spray or air cooling system. After the bar has been shaped and cooled, it is cut into the desired lengths. The cut bars then undergo further processes, including straightening, surface treatment, and quality testing. These additional steps guarantee that the steel round bars meet the required specifications and standards. In conclusion, the production of steel round bars involves heating a steel billet, passing it through a series of rolling stands to shape it into a round bar, cooling it, and cutting it into the desired lengths. This process enables the creation of robust and long-lasting round bars that serve various applications in industries like construction, manufacturing, and engineering.

- Q: What are the advantages of using steel round bars compared to other materials?

- Steel round bars offer several advantages over other materials. Firstly, steel is known for its exceptional strength and durability. With its high tensile strength, steel can withstand heavy loads and pressure without deforming or breaking. This makes steel round bars perfect for applications that require structural support or load-bearing capabilities. Furthermore, steel is a highly versatile material that can be easily shaped and molded into various forms, including round bars. This flexibility in design makes steel round bars suitable for a wide range of applications, whether it be in construction, manufacturing, or the automotive industry. They can be customized to meet specific requirements. In addition to its strength and versatility, steel is also corrosion-resistant. It naturally resists rust and other forms of corrosion, making it ideal for both indoor and outdoor use. Steel round bars can withstand exposure to moisture, chemicals, and harsh environmental conditions, ensuring their longevity. Another advantage of steel round bars is their cost-effectiveness. Although the initial cost of steel may be higher than that of other materials, its long-term benefits and durability make it a cost-effective choice. Steel round bars require minimal maintenance and can last for decades without the need for replacement or repair, resulting in significant cost savings over time. Moreover, steel is a sustainable material. It is 100% recyclable and can be reused multiple times without losing its properties or quality. By choosing steel round bars, one contributes to reducing waste and conserving resources, making it an environmentally friendly choice. In conclusion, the strengths of steel round bars compared to other materials lie in their strength, versatility, corrosion resistance, cost-effectiveness, and sustainability. These qualities make steel round bars the preferred choice for various applications, guaranteeing long-lasting and reliable performance.

- Q: How do you store and handle steel round bars?

- Steel round bars should be stored in a dry and covered area to protect them from moisture and corrosion. They should be stacked horizontally on a flat surface, with spacers in between each layer to prevent deformation. When handling steel round bars, it is important to wear appropriate protective gear such as gloves and safety shoes. They should be lifted using proper lifting equipment, ensuring that the load is evenly distributed. Additionally, bars should not be dragged or rolled on the ground to avoid scratches or damage.

Send your message to us

Q235 Stainless high quality steel round bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords