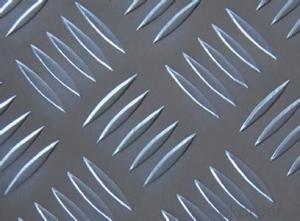

Checkered Plate Set

Checkered Plate Set Related Searches

Diamond Checkered Plate Stainless Checkered Plate Aluminium Checkered Plate Aluminum Checkered Plate Ss Checkered Plate Cheap Checkered Plate Checkered Nail Stamping Plate Polished Aluminum Checker Plate Checker Plate Aluminum Checker Plate Aluminum Sheets A786 Checkered Plate Aluminum Checker Plate Sheet Checkered Plate Standard Sizes Aluminium Checkered Plate Price 1 4 Aluminum Checker Plate Black Aluminum Checker Plate 1/8 Aluminum Checker Plate Cast Iron Plate Aluminum Checker Plate For Sale Diamond Checker Plate Aluminum Decorative Steel Plate Aluminum Seder Plate 1 8 Aluminum Checker Plate 1/4 Checkered Plate Weight Polishing Aluminum Checker Plate Polishing Checker Plate Aluminum Astm A786 Checkered Plate Stainless Steel Dinnerware Set Aluminum Checker Plate Near Me Ceiling Light Mounting PlateCheckered Plate Set Supplier & Manufacturer from China

A Checkered Plate Set is a versatile and essential tool for various industries, including construction, automotive, and manufacturing. This set typically consists of a collection of steel plates with a checkered or serrated surface, designed to provide grip, support, and stability in different applications. The unique pattern on these plates helps prevent slipping and ensures safety in both indoor and outdoor environments.The Checkered Plate Set is widely used in numerous scenarios, such as flooring, ramps, walkways, and platforms, where slip resistance is crucial. It is also commonly employed in workshops, factories, and warehouses to enhance safety and efficiency. Additionally, these plates can be utilized as a protective layer for various surfaces, such as machinery and equipment, to prevent damage and wear.

As a leading wholesale supplier, Okorder.com offers a vast inventory of Checkered Plate Sets to cater to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Checkered Plate Set meets the highest industry standards and is available at competitive prices.

Hot Products