Suspension Ceiling System, Ceiling T Grid

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

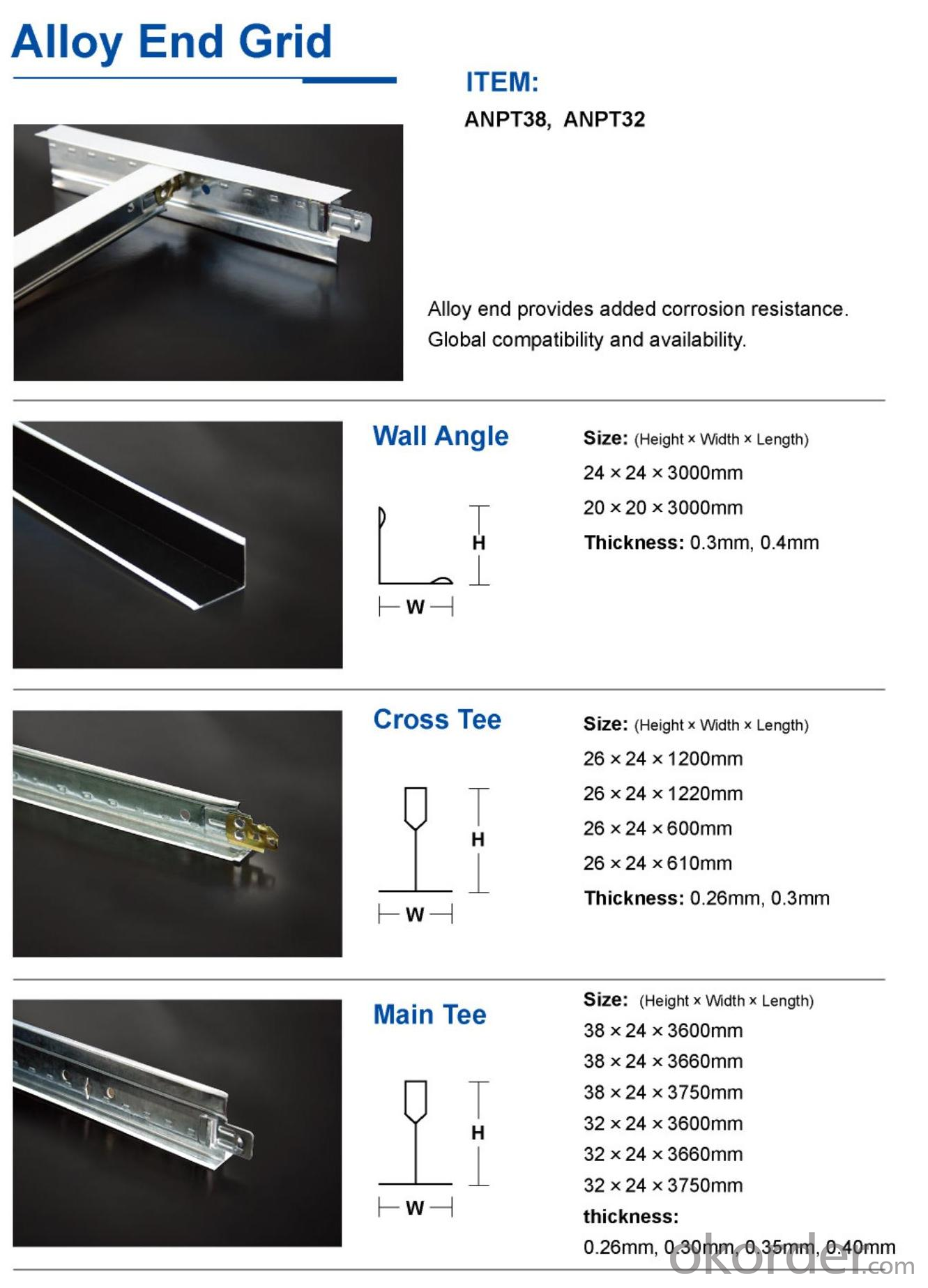

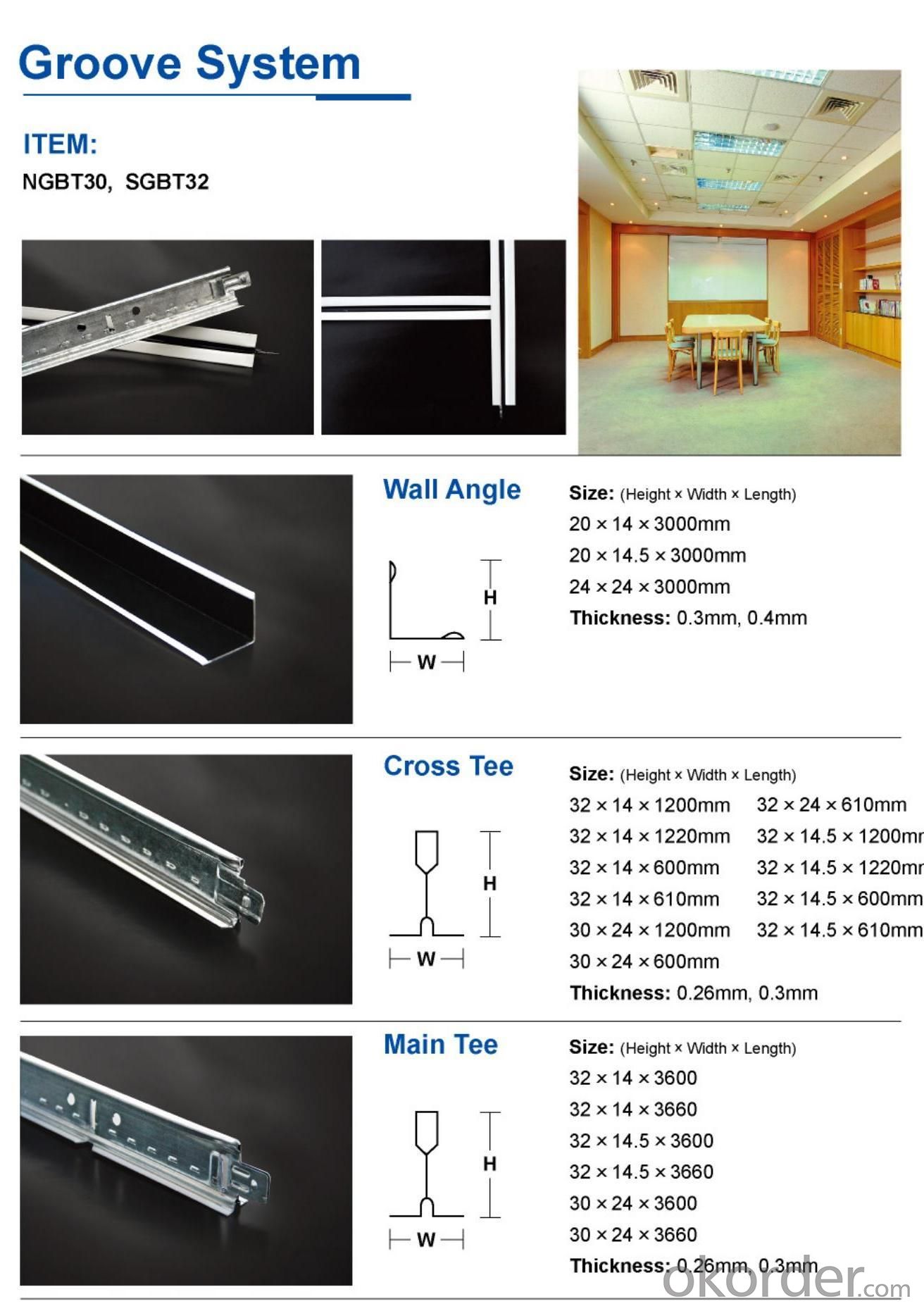

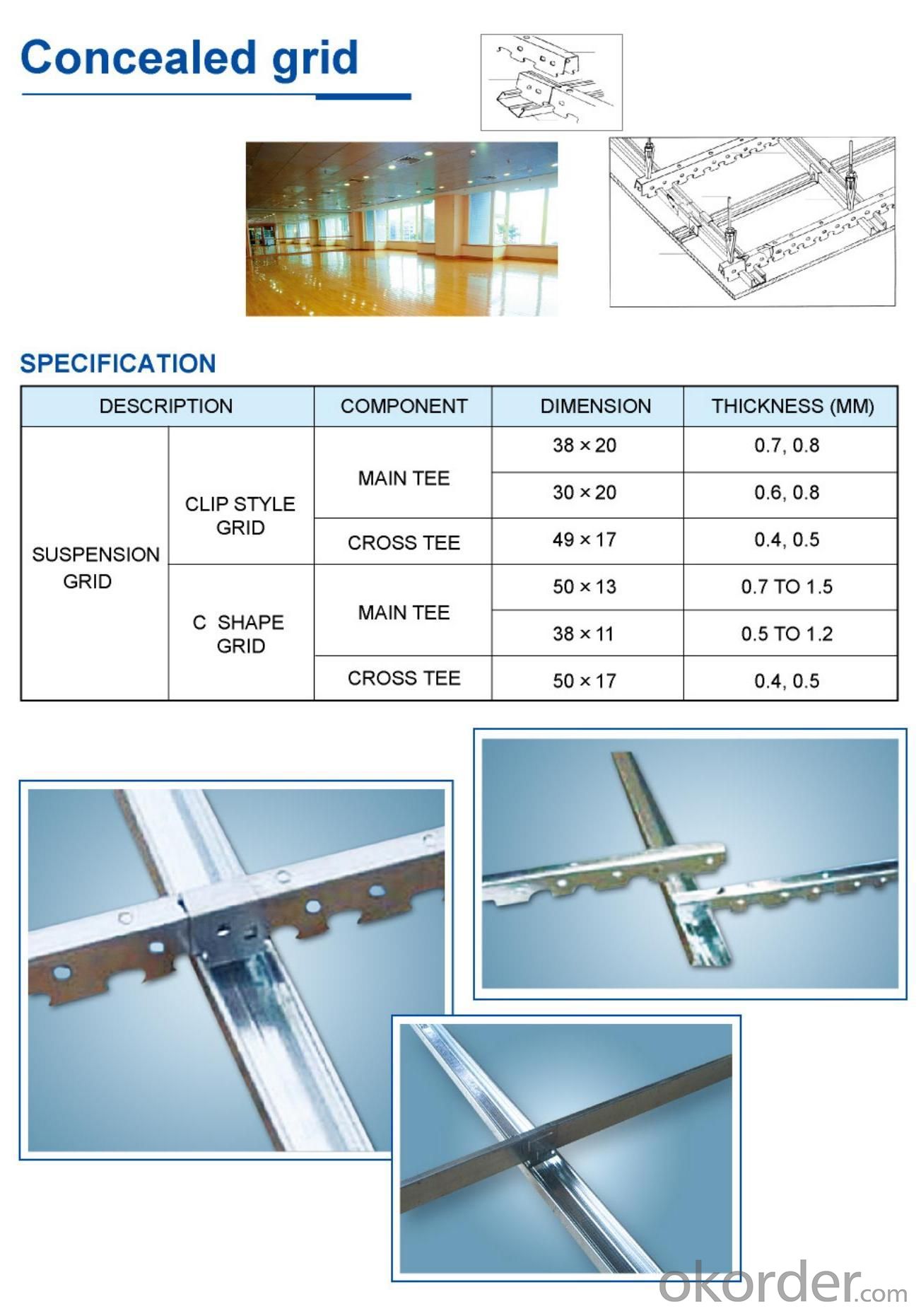

Specification

The grille ceiling system enables open ceiling plane constructions, offering a wide variety of cells and patterns for maximum design freedom. Our panels are created using a proprietary manufacturing process that ensures clean lines and durability. Our products include:

Glass Wool Ceiling

Rock Wool Ceiling

Vinyl Laminated Gypsum Ceiling

Metal Ceiling

Ceiling Grid and Accessories

Product Applications:

Sustainable, accessible, economical, commercial ceiling suspension

Product Advantages:

1. Anti-tiding,shape keeping,and easy to be installed

2. All components can provide a square, level and maintain integrity of systems

3. System is engineered and designed fit and provide a finish to coordinate with all of ingenuity systems

Product Specifications:

Installation Instructions:

1.According to the design drawing,determine the ceiling height. Mark the desired height at each room comer then make a perimeter chalk line,which should be 20mm above your desired ceiling height.

2.Install hangers and fasteners--snap a chalk line for the main tees, attach hangers and wires.

3. Install main tees-pull each hanger wire through the hanger hole in the tee,bend the wire up and wrap it around itself three times.Then continue to insert all other hanger wires.The intervals of two main tees should be1220mm/1200mm.

4.Install cross tees-push cross tee end through the main tee slot until the sound"click".Fasten the cross tees.The intervals of two cross tees should be 610mm/600mm.

5.Lay in the ceiling panels-slightly tilt each panel up through the opening and lower it to rest squarely on all four tees.

6.Important notice:lighting and other fixtures must be supported by the grid,not by the ceiling panels.

FAQ:

Q:How many the warranty years of your products?

A:15 years for indoor used,20 years for ourdoor used.

Q:Can you show me the installation instruction?

A:Yes,our engineering department is in charge of helping your installation.any question,you can let me know.

Images:

- Q: Light steel keel sticking wood finishes is not to block the blockboard?

- Not necessarily Oh, you can also use the European pine board

- Q: Light steel keel what accessories

- Ceiling keel is divided into 50 series and 60 series, wall keel series is generally divided into 75,100 series, you have to ask which one

- Q: How to remodel kitchen with dropped ceiling?

- Depends on what is above the ceiling tile, assuming that you have a grid and tile drop ceiling. If all that is above the drop ceiling is drywall or plaster, I would remove the grid, patch and paint to get the taller ceiling back unless it is ridiculously high.

- Q: each point on the grid. The weight of each 4x4 area is 144# ( square footage is 9# PSF ) which I divide into four seperate areas and come up with a reaction so I know what spring to use at each point. The basic areas are easy to calculate because it's either rectangular or square but some areas are cut up, for example there are areas shaped like an L on the grid with two rectangular sides and I don't know how to get their reaction because there are more than four points. Could someone show me a formula for this?

- Sounds like you will probably need to break up the oddly shaped areas, and consider them as a collection of rectangles. However, my understanding is still a little fuzzy. What's this reaction stuff? I don't have a clear picture of the layout in my head.

- Q: For example, T-keel ah, triangular keel ah, aluminum keel ah, etc., belong to the paint keel it

- There are light steel partition, there are keels, that is the other cross-sectional shape.

- Q: Material used in False Ceiling?

- A false or dropped ceiling can be made of various materials. Most commonly, they are made of ceiling tiles or panels that are suspended from a grid of wires and tracks.

- Q: U-type and C-type light steel keel purposes

- U-shaped keel stone keel, fixed in the walls around;

- Q: I am planning my basement remodel and love the idea of a tongue and groove look for the ceiling. Is it possible to use painted wall panels screwed into the ceiling beams? That way the mechanics of the house can still be accessed but I don't have an ugly drop ceiling.

- Yes, we did this in our basement. I would just caution, to try and find lighter tongue and groove. They also have dropped ceiling tiles now that you can attach directly to the ceiling without the metal grids. I saw one just recently at a hardware store (in Canada) that looked exactly like our tongue and groove wooden ceiling. GOOD LUCK>

- Q: Light steel keel expensive or aluminum alloy keel expensive? What are the characteristics of each

- There is a kind of paint keel is made of iron. Also T-type. But relatively soft. Own grasp.

- Q: Do the ceiling, the general use of what kind of specifications gypsum board and light steel keel?

- Ceiling more use 9.5mm, 12mm, 12.7mm thick gypsum board;

Send your message to us

Suspension Ceiling System, Ceiling T Grid

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords