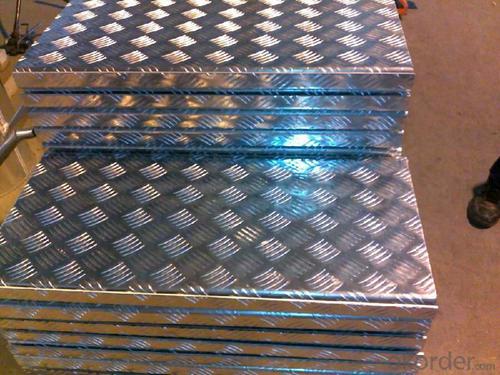

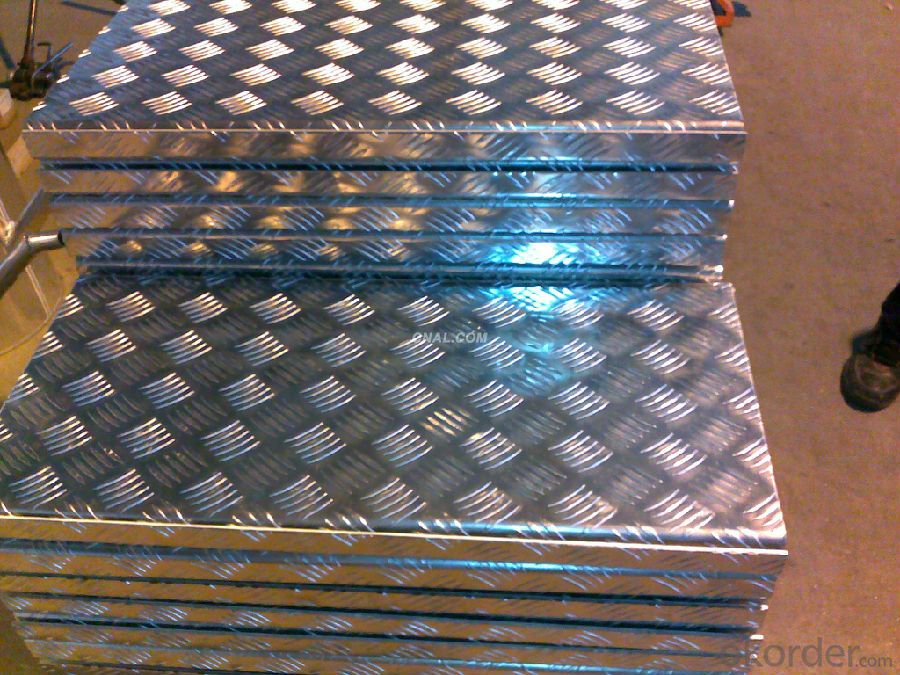

Sheets Aluminum Flooring Anti-Slip Checker Embossed Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

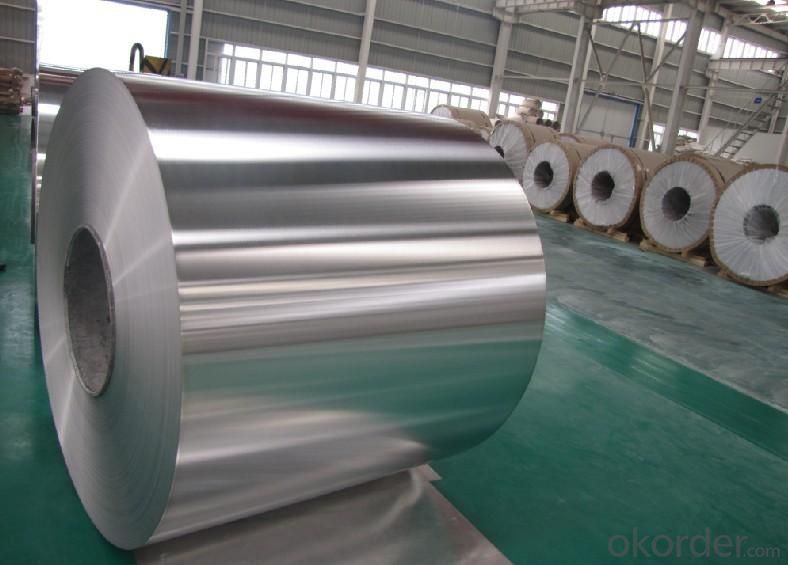

Aluminum Flooring Anti-slip Checker Embossed Sheet Plate

Description

Aluminium Sheet | ||||||

Alloy | Thickness(mm) | Width(mm) | Length(mm) | Temper | DC or CC | |

1050,1060,1070,1100,1235 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

4.0-150 | 1000-1900 | H112,H111 | DC | |||

3003,3004,3105 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

4.0-150 | 1000-1900 | H112,H111 | DC | |||

5052,5083,5754 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC | |

4.0-150 | 1000-1900 | H112, H111 | DC | |||

8011 | 0.08-0.20 | 400-1500 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC | |

Packing | Export standard wooden packing | |||||

Application | Mainly in Construction , decoration, PCB materials, cover material, piping, refrigeration, air conditioner, automobile, etc. | |||||

MOQ | 5MT | |||||

Kind attention | Specifications can be customized as the customer’s requirements. | |||||

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: Can someone please explained what aluminum reacts slowly with dilute acided?Thank you!

- Aluminum metal is not very reactive because of the passivating layer of aluminum oxide, Al2O3, on the surface of the metal. The oxide coating can be dissolved by solutions which are either very acidic or very basic. ======== Follow up ======== Whoa, Nellie. Back the boat up. The oxide coating on aluminum comes from oxygen in the air and covers the surface of the aluminum long before it landed in the acid solution. The dissolved oxygen in the acid solution is NOT the reason for oxygen combining with aluminum. The pH of the solution has little influence on the amount of dissolved oxygen. The partial pressure of O2 above the water and the temperature of the water are much more important to the amount of dissolved oxygen.

- Q: What are the different surface finishes for aluminum sheets in the construction industry?

- In the construction industry, there are several different surface finishes that can be applied to aluminum sheets. These finishes are designed to enhance the appearance and durability of the aluminum, making it suitable for various construction applications. One common surface finish for aluminum sheets is mill finish. This finish is the raw, untreated surface of the aluminum, which may have some minor imperfections or scratches. Mill finish is often used in applications where appearance is not a major concern, such as structural components or industrial projects. Another popular surface finish is anodized finish. Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum, making it more resistant to corrosion and wear. Anodized finishes can come in a variety of colors, allowing for greater design flexibility in construction projects. This finish is commonly used for architectural elements, such as window frames, facades, and decorative panels. Painted finishes are also commonly used in the construction industry. Aluminum sheets can be coated with a layer of paint, which provides both aesthetic appeal and additional protection against corrosion. Painted finishes can be customized to match specific design requirements, making them suitable for a wide range of construction applications. Additionally, brushed finishes are often used in the construction industry. Brushing is a mechanical process that creates a textured surface on the aluminum, resulting in a distinctive, matte appearance. This finish is commonly used for decorative purposes, such as interior wall panels or furniture in commercial spaces. In summary, the construction industry offers a variety of surface finishes for aluminum sheets. These finishes include mill finish, anodized finish, painted finish, and brushed finish. Each finish has its own unique properties and benefits, allowing for greater versatility and customization in construction projects.

- Q: What is the width and length of the aluminum sheets?

- Depending on the specific product or manufacturer, the aluminum sheets' width and length may differ. To obtain accurate measurements, it is advisable to consult the product specifications or get in touch with the manufacturer.

- Q: Is it possible to utilize doors constructed from recycled materials for a project?

- <p>Yes, you can use doors made from recycled materials in your project. These doors are not only environmentally friendly but also help reduce waste. They can be made from a variety of recycled materials, including plastic, metal, or wood. Ensure that the recycled doors meet the necessary safety and quality standards for your project. It's also important to consider the durability and performance of these doors, as they should be able to withstand regular use and maintain their integrity over time.</p>

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces. Aluminum is known for its high reflectivity, making it a popular choice for various applications that require reflective surfaces. Aluminum sheets can be polished to a high shine, allowing them to reflect light and create a mirrored effect. This makes them ideal for uses such as reflectors in lighting fixtures, solar panels, mirrors, and decorative purposes. Additionally, aluminum's reflective properties make it suitable for applications where heat reflection is required, such as in thermal insulation or roofing materials. Overall, aluminum sheets are a versatile and effective option for creating reflective surfaces.

- Q: aluminum is 2.82x10^-8 ohm-m

- Aluminum with the same resistance as 50 meters of copper. (Resistance) = (Resistivity)(Length/Area) So if the resistivity changes by (2.82/1.72), then the length changes by (1.72/2.82). So the length of aluminum would be 50m(1.72/2.82) Length of aluminum would be 30.5 meters

- Q: Is it possible to use aluminum sheets in extreme weather conditions, including very hot and very cold temperatures?

- <p>Yes, aluminum sheets can be used in harsh environments, including hot and cold climates. Aluminum is known for its excellent corrosion resistance and durability, making it suitable for various weather conditions. It does not rust and maintains its strength in both low and high temperatures. However, it's important to consider the specific alloy and protective coatings used, as these can affect performance in extreme conditions. Properly treated and coated aluminum can withstand significant temperature fluctuations without significant degradation.</p>

- Q: Can aluminum sheets be etched or engraved?

- Yes, aluminum sheets can be etched or engraved.

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties, making it a popular choice for marine applications. It forms a protective oxide layer that prevents further corrosion, making it durable and long-lasting in saltwater environments.

- Q: What oil does the aluminum plate stretch with?

- There are professional tensile oil, you can ask to pull the rice cooker liner manufacturers know, if not a lot of production, you can use peanut oil first try, the effect barely enough!

Send your message to us

Sheets Aluminum Flooring Anti-Slip Checker Embossed Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords