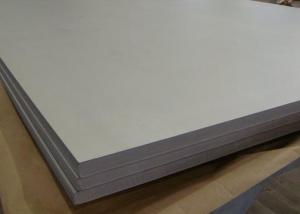

Stainless Steel Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 3500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Can stainless steel strips be painted?

- Yes, stainless steel strips can be painted. However, it is important to properly prepare the surface by cleaning it thoroughly and applying a suitable primer before painting to ensure good adhesion and long-lasting results.

- Q: Are 111 stainless steel strips suitable for heat sinks?

- 111 stainless steel strips are unsuitable for heat sinks. Heat sinks are designed to effectively dissipate heat from electronic components and thus require materials with high thermal conductivity. Although stainless steel has numerous desirable properties, it lacks good thermal conductivity, particularly when compared to other metals like aluminum or copper that are commonly used for heat sinks. Consequently, it is advisable to utilize materials with higher thermal conductivity for heat sinks in order to guarantee efficient heat dissipation.

- Q: What is the thermal expansion coefficient of stainless steel strips?

- The thermal expansion coefficient of stainless steel strips can vary depending on the specific grade of stainless steel being used. However, in general, stainless steel has a relatively low coefficient of thermal expansion compared to other materials. The coefficient of thermal expansion is a measure of how much a material expands or contracts when exposed to changes in temperature. Stainless steel typically has a coefficient of thermal expansion ranging from about 10 to 17 µm/m°C (micrometers per meter per degree Celsius). This means that for every degree Celsius increase in temperature, a stainless steel strip will expand by approximately 10 to 17 micrometers per meter in length. It is important to note that the exact coefficient of thermal expansion may vary depending on the specific alloy composition and heat treatment of the stainless steel. Therefore, it is recommended to consult the manufacturer's specifications or conduct specific testing to determine the precise thermal expansion coefficient of a particular stainless steel strip.

- Q: Are stainless steel strips suitable for outdoor sculptures?

- Yes, stainless steel strips are suitable for outdoor sculptures. Stainless steel is known for its corrosion resistance, which makes it an excellent choice for outdoor applications. It is highly resistant to rust and can withstand harsh environmental conditions such as rain, snow, and direct sunlight. Additionally, stainless steel has a sleek and modern appearance that can enhance the aesthetic appeal of outdoor sculptures. It is also a durable and strong material, which ensures that the sculptures will remain intact and sturdy over time. Overall, stainless steel strips are a great choice for outdoor sculptures due to their corrosion resistance, durability, and aesthetic qualities.

- Q: What are the different types of surface finishes available for stainless steel strips?

- There are several different types of surface finishes available for stainless steel strips, each offering unique properties and aesthetic appeal. Some of the most common types include: 1. No. 1 Finish: This is a hot-rolled, annealed, and pickled finish that exhibits a rough and dull appearance. It is commonly used for applications where a rough texture is desired or for further processing. 2. No. 2B Finish: This finish is achieved by cold-rolling stainless steel strips and subsequently annealing them in a controlled atmosphere. It results in a smooth, reflective surface that is suitable for general applications requiring a bright and uniform appearance. 3. No. 2D Finish: Similar to the No. 2B finish, this surface finish is achieved by cold-rolling stainless steel strips and annealing them in a hydrogen atmosphere. It provides a slightly duller and less reflective surface compared to the No. 2B finish. 4. No. 3 Finish: Also known as a ground finish, it is achieved by mechanically polishing the surface of stainless steel strips using abrasive belts or brushes. This finish creates a semi-reflective appearance with a linear grain pattern. 5. No. 4 Finish: This is a popular finish for decorative applications, achieved through the use of polishing belts or brushes. It produces a brushed appearance with a consistent grain pattern, providing a satin-like finish. 6. No. 6 Finish: This is a high-gloss finish that is obtained through polishing stainless steel strips with successively finer abrasives. It offers a reflective and mirror-like appearance, making it suitable for decorative applications. 7. No. 7 Finish: Similar to the No. 6 finish, this is achieved by polishing stainless steel strips with successively finer abrasives. However, it is then buffed to create a highly reflective finish with enhanced clarity and depth. 8. No. 8 Finish: Often referred to as a mirror finish, this is the highest level of polish available for stainless steel strips. It is achieved through polishing with extremely fine abrasives, resulting in a flawless, highly reflective, and mirror-like surface. 9. Bead Blasting Finish: This finish is achieved by propelling small glass beads or steel shots at the surface of stainless steel strips. It creates a uniform matte appearance with a slightly rough texture. 10. Electropolished Finish: This is a specialized finish that involves the use of an electrolytic bath to remove a controlled amount of metal from the surface of stainless steel strips. It results in a smooth, bright, and clean finish with enhanced corrosion resistance. These various surface finishes offer a range of appearances and functional properties, allowing stainless steel strips to be utilized in a wide array of applications, from architectural and decorative to industrial and sanitary.

- Q: What is the magnetic permeability of stainless steel strips?

- The magnetic permeability of stainless steel strips is typically low, making them less susceptible to magnetism compared to other materials.

- Q: Can stainless steel strips be bent or folded without cracking?

- Yes, stainless steel strips can be bent or folded without cracking, as they possess high ductility and strength.

- Q: What is the hardness of stainless steel band 3/4?

- 1/2 hardness range: HV250 degrees to HV2903/4 hardness range: HV310 to HV370(HV:, Vivtorinox hardness)

- Q: Can stainless steel strips be used in harsh weather conditions?

- Stainless steel strips are capable of withstanding even the harshest weather conditions. Renowned for its outstanding resistance to corrosion, stainless steel is highly impervious to rust and other forms of deterioration caused by exposure to moisture, humidity, and extreme temperatures. Consequently, stainless steel strips prove to be a dependable and long-lasting choice for various applications that experience adverse weather, such as outdoor structures, building facades, roofing, and marine environments. The corrosion resistance of stainless steel can be attributed to the presence of chromium within its composition, which creates a protective layer on the metal's surface, preventing it from reacting with the surrounding environment. Moreover, stainless steel also possesses resistance to UV radiation and can endure strong winds, making it a suitable option for regions prone to storms and hurricanes. In conclusion, stainless steel strips offer an outstanding solution for applications that necessitate strength, durability, and the ability to withstand harsh weather conditions.

- Q: Can 111 stainless steel strips be used in the pulp and paper industry?

- Yes, 111 stainless steel strips can be used in the pulp and paper industry. Stainless steel strips are known for their corrosion resistance, durability, and strength, making them suitable for various industrial applications, including the pulp and paper industry.

Send your message to us

Stainless Steel Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 3500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords