4x8 1.0mm 304 Mirror Finished Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

4x8 1.0mm 304 Mirror Finished Stainless Steel Sheet

Product Description

Item Type | 4x8 1.0mm 304 Mirror Finished Blue Color Coated Stainless Steel Sheet |

Material | 201, 304, 410,430, 316 stainless steel coils & sheets & strip |

Standard | ASTM240 AISI GB DIN JIN |

Thickness | 0.15mm-4.0mm or Customized |

Specification | 1m*2m . 4ft*8ft. 4ft*10ft or Customized |

Width | 1000mm, 1219mm or Customized |

Length | 2000mm, 2438mm, 3048mm or Customized |

Surface Polishing | No.1, 2B, BA, Mirror, 8K,10K, BA, Brushed,No.4, Hairline, Grit: #180 #240 #280,#320 |

Surface Finishing | Etched Finish |

Color | Golden, Black Golden, Champagne Gold, Rose Golden, Dusk, Azure, Sapphire, Bronze, Antique Brass, Bronze, Wine Red, Chinese red, Rose red, Tawny, Violet, etc |

Test | Eddy current/hydrostatic, mechanical, chemical composition analysis. |

Packaging | Wooden Box, Steel Box, Standard Seaworthy |

Application | Art Decoration, Partition Screen, Door, Lift Decoration, Wall Decoration, Cover Panel, Table top, and or decorative surface. Used in construction, chemical industry, electricity industry, food service industry, paper-making industry, and so on. |

Delivery time | 15-35 days after order confirmed |

Payment | T/T, L/C, D/A, D/P |

Note | We can provide other sizes, pattern and color by customers’ requirement |

Chemical Composition | ||||

SS304 | SS 316 | SS430 | SS201 | |

Ni(%) | 8.0-10.5 | 10.0-14.0 | -- | 0.8-1.2 |

Cr(%) | 18.0-20 | 16.0-18.0 | 16.0-18.0 | ≤0.15 |

C(%) | ≤0.08 | ≤0.08 | ≤0.12% | ≥40 |

Elong(%) | ≥40 | ≥40 | ≥22 | |

Hardness | HB≤187,HRB≤90, HV≤200 | HB≤187, HRB≤90 HV≤200 | HB≤183, HRB≤88 HV≤200 | HB≤241,HRB≤100, HV≤240 |

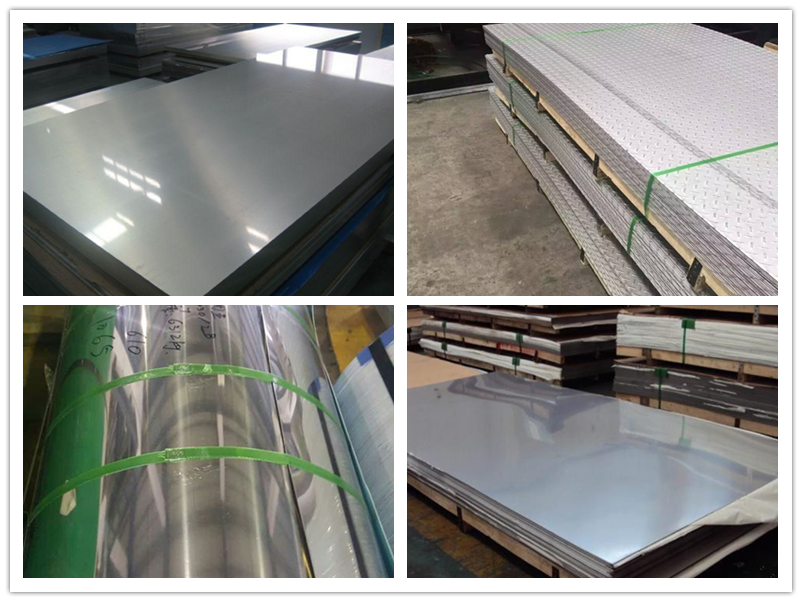

Stainless Steel Sheet Series

Stainless Steel Polished Sheet (8K Mirror, Hairline, Grit 240,320)

Embossed Stainless Steel Sheet

Etched Stainless Steel Sheet,

PVD Colored Stainless Steel Sheet,

Perforated Stainless Steel Plate

Chequered Stainless Steel Sheet

Product Pictures:4x8 1.0mm 304 Mirror Finished Stainless Steel Sheet

Detailed Images

Packaging & Shipping

Application

- Q: Can stainless steel sheets be used for electrical conductivity?

- Yes, stainless steel sheets can be used for electrical conductivity as they have relatively low electrical resistance and are often used in applications where electrical current needs to flow efficiently.

- Q: Can stainless steel sheets be used for outdoor railings?

- Outdoor railings can indeed utilize stainless steel sheets. The reason behind the popularity of stainless steel for outdoor applications is its durability and resistance to corrosion. This material can endure exposure to various weather conditions, including rain, snow, and sunlight, without deteriorating or rusting. In addition to providing a sleek and modern appearance to outdoor spaces, stainless steel railings also offer strength and stability. Furthermore, they are low maintenance and easy to clean, making them an ideal choice for outdoor railings that may accumulate dirt, dust, or other debris. In conclusion, stainless steel sheets are an outstanding option for outdoor railings, as they combine aesthetic appeal with long-lasting performance.

- Q: Are stainless steel sheets good for cryogenic storage?

- Yes, stainless steel sheets are suitable for cryogenic storage due to their excellent resistance to low temperatures and high strength. They can withstand extreme cold without becoming brittle or losing structural integrity, making them a reliable choice for storing materials at cryogenic temperatures.

- Q: Are stainless steel sheets suitable for elevator control panels?

- Yes, stainless steel sheets are suitable for elevator control panels. Stainless steel is a durable and resistant material that can withstand various environmental conditions, including frequent use and exposure to moisture, heat, and chemicals. Elevator control panels often require a material that is easy to clean, resistant to scratches and dents, and aesthetically pleasing. Stainless steel meets all these criteria, making it an ideal choice for elevator control panels. Additionally, stainless steel has a sleek and modern appearance, which can enhance the overall design of the elevator interior.

- Q: What are the cost considerations when purchasing stainless steel sheets?

- There are several cost considerations to bear in mind when buying stainless steel sheets. The cost is greatly influenced by the grade of stainless steel. Stainless steel comes in different grades, each with its own properties and levels of corrosion resistance. Higher grades like 316 or 304 are generally more expensive due to their superior corrosion resistance and durability. The size and thickness of the sheets also impact the cost. Thicker sheets are generally more expensive than thinner ones, and larger sheets are priced higher than smaller ones. It's important to accurately determine the required size and thickness to avoid unnecessary expenses. The surface finish is another factor that can affect the cost. Stainless steel sheets are available in various finishes, including brushed, mirror, or matte. Finishes that require additional processing or polishing usually add to the overall cost. Moreover, the quantity of sheets needed can have an impact on pricing. Bulk purchases often come with discounts or lower per-unit costs compared to buying small quantities. Transportation and delivery costs should also be taken into account. Stainless steel sheets are heavy and can be costly to transport, especially if shipping over long distances. These costs should be factored in to ensure that the overall purchase remains within budget. Finally, it is crucial to consider the reputation and reliability of the supplier. While lower-priced options may be tempting, it's important to ensure that the supplier offers high-quality stainless steel sheets that meet the required specifications. Purchasing from a reputable supplier may come at a slightly higher cost, but it guarantees the quality and reliability of the product. In conclusion, when purchasing stainless steel sheets, it's vital to consider the grade, size, thickness, surface finish, quantity, transportation costs, and the reputation of the supplier. By carefully considering these factors, one can make an informed decision that balances cost-effectiveness with the desired quality and specifications.

- Q: Are stainless steel sheets suitable for medical equipment or devices?

- Yes, stainless steel sheets are commonly used in the manufacturing of medical equipment or devices due to their excellent corrosion resistance, durability, ease of cleaning, and ability to withstand sterilization processes.

- Q: How do I clean and maintain stainless steel sheets?

- To effectively clean and maintain stainless steel sheets, adhere to these straightforward guidelines: 1. Commence by eliminating any loose dirt or debris from the surface. Employ a soft cloth or sponge soaked in warm water. 2. For more stubborn stains or fingerprints, combine a mild detergent with warm water. Administer this mixture to the sheet using a non-abrasive sponge or cloth. Thoroughly scrub the affected area, following the grain's direction. 3. Rinse the sheet meticulously with clean water, ensuring the removal of any detergent residue. 4. To prevent the formation of water spots or streaks, delicately dry the stainless steel sheet with a soft cloth. 5. For sustained shine and future stain protection, apply a small quantity of stainless steel cleaner or polish to a clean, soft cloth. Employ circular motions, avoiding any circular rubbing. 6. Eliminate any surplus cleaner or polish using a separate clean cloth, guaranteeing a uniform finish. 7. In cases of obstinate stains or scratches, a stainless steel cleaner containing mild abrasives may be utilized. However, exercise caution as improper usage may result in surface scratching. 8. Refrain from utilizing abrasive sponges, steel wool, or harsh chemicals, as these substances can inflict damage upon the stainless steel surface. 9. Regularly dust the stainless steel sheets with a soft cloth to deter the accumulation of dirt or dust particles. 10. Lastly, it is essential to consult the manufacturer's instructions for specific cleaning and maintenance recommendations tailored to your particular stainless steel sheet product.

- Q: What is the modulus of elasticity of stainless steel sheets?

- The modulus of elasticity of stainless steel sheets typically ranges from 190 to 220 gigapascals (GPa).

- Q: Can stainless steel sheets be used for signage or lettering?

- Yes, stainless steel sheets can be used for signage or lettering. Stainless steel is a durable and versatile material that is resistant to corrosion, making it suitable for outdoor applications. It can be cut into various shapes and sizes, allowing for customized signage and lettering designs. Additionally, stainless steel can be finished in different ways, such as brushed or polished, to achieve the desired aesthetic.

- Q: Are stainless steel sheets suitable for cryogenic storage containers?

- Indeed, cryogenic storage containers are well-suited for stainless steel sheets. Renowned for its outstanding qualities at low temperatures, stainless steel proves to be an optimal option for cryogenic purposes. Its remarkable resistance to thermal expansion and contraction minimizes the risk of cracking or leaking even in extremely low temperatures. Moreover, stainless steel boasts exceptional durability and corrosion resistance, enabling it to endure the harsh conditions of cryogenic storage and guarantee the safety and integrity of stored materials. Consequently, stainless steel sheets find extensive application in the creation of cryogenic storage containers across diverse industries, including pharmaceuticals, aerospace, and scientific research.

Send your message to us

4x8 1.0mm 304 Mirror Finished Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords