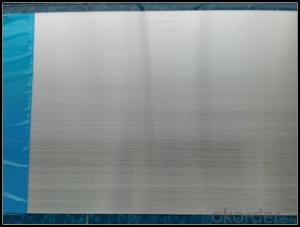

1.8mm Brushed Coated Aluminium Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

2.Our advantage

Our quality best, service best, price better!

3.Specification and application

Alunimiun Sheet

ALLOY: AA1*** (AA1050,AA1060,AA1070,AA1100 etc.)

AA3*** (AA3003,AA3004,AA3005,AA3105 etc.)

AA5*** (AA5052,AA5083,AA5754 etc)

AA8*** (AA8011,AA8006 etc)

TEMPER: H14,H16,H18,H22,H24,H26,H32,O/F

THICKNESS: 0.2mm-100mm

WIDTH: 30mm-1700mm

STANDARD: GB/T 3880-2006

Special specification is available on customer's requirement

SURFACE QUALITY: GOOD APPEARANCE WITH NO-CRACK AND WELL-DISTRIBUTE GRAIN.

BUILD UP: TIGHT SLIT EDGES FREE FROM CRACKS, LAYER TO LAYER SHIFT NOT MORE THAN 2MM.

PROFILE: -0/+1%

FLATNESS: MILL FLATNESS COIL HAVING EDGE WAVINESS RATHER THAN CENTER BUCKLES SHALL BE ACCEPTABLE.

ROLLING PERFORMANCE: RE-ROLLABLE TO THE FINAL DESIRES GAUGES

4.Pictures

5.FAQ

1)Can we supply samples?

Yes, we can!

2)What can you do if you have other quastions?

You can contact us freely at any time!

Construction is one of the three major markets of aluminum sheets, about 20% of the world's total output of aluminum for the construction industry, a number of aluminum constructions in industrial countries, the amount of aluminum accounts for more than 30% of its total production. In recent years, aluminum construction products constantly updated, color aluminum, aluminum composite, composite door window frames, aluminum templates novel application of building products has also increased. China has been used in industrial and civil construction in aluminum alloy roof, walls, doors and windows, and gradually extended to external decoration, construction template, etc., we have achieved good results.

The most important feature of aluminum is light weight and weighs only 1/3 of steel, but the intensity (the ratio of ultimate strength and specific gravity) can reach or exceed the structural steel. Secondly, aluminum easily processed into various shapes, can adapt to a variety of process connections, thus providing favorable conditions for the construction of the structure using the most economic justice sectional form. Therefore, the use of aluminum not only can greatly reduce the weight of the building, saving construction materials, but also reduce transport member, installation work, and speed up the construction progress. This earthquake zone and inaccessible mountainous and remote areas, its economic effect is more obvious. Aluminum luster appearance, corrosion resistance, high reflectance of light and heat, sound absorption performance is good, get a variety of colors by chemical and electrochemical methods. Therefore, aluminum is widely used in industrial and civil construction of the roof, walls, doors, windows, frame, both interior and exterior panels, ceiling, ceiling, handrails, indoor furniture, container and store templates used in construction.

According to their mode of production, aluminum sheet can divided into forged aluminum and wrought aluminum alloy two categories. On the general, deformation of aluminum alloy for rolled sheet, foil, strip, extruded rods, tubes or profiles of complex shape are used in building. Deformation of aluminum alloy their function, for different purposes, divided into rust-proof aluminum, hard aluminum, super-hard aluminum and special aluminum. Buildings generally use rust-proof aluminum and aluminum alloy wrought aluminum.

- Q: What is the difference between aluminium plate 5A05 and 5A06?

- The aluminum plate doesn't have this material. Have you made a mistake?Give you a full one,1, pure aluminum: Material: 1050/1060/1070/1100/ 1200/ thickness: 0.1---20mm width: 800---2200mm2, alloy aluminum: Material: 2A21/3003/5052/5083/6061/6082 /8011 thickness: 0.5---260mm width: 800---2800mm3 curtain wall Kaiping aluminum plate: Material: 1060/1100 thickness 0.95, 1.35, 1.85, 2.35, 2.7, 2.85mm, width 0.8---1.5m

- Q: Are there any health risks associated with using aluminum sheets?

- Yes, there are potential health risks associated with using aluminum sheets. Aluminum is a neurotoxic metal that can accumulate in the body over time. Prolonged exposure to high levels of aluminum has been linked to several health issues, including respiratory problems, bone disorders, and neurodegenerative diseases such as Alzheimer's. Additionally, certain studies suggest a possible link between aluminum exposure and an increased risk of developing breast cancer. It is important to take precautions when working with aluminum sheets and minimize exposure to the metal.

- Q: What does exterior wall imitate aluminium paint have? Imitate aluminium plate paint is fluorocarbon paint?

- The exterior walls are painted with aluminium and plastic panels, and only fluorocarbon metal paint is used. The fluorine content determines the service life;The construction technology of fluorocarbon metal paint is relatively complex, and the price is more expensive, generally including the construction is roughly equivalent to more than half the price point to use aluminum plate;

- Q: Can aluminum sheets be used for heat shields in appliances?

- Yes, aluminum sheets can be used as heat shields in appliances. Aluminum is a good conductor of heat, making it an effective material for dissipating and reflecting heat away from sensitive components in appliances. Additionally, aluminum is lightweight, durable, and has good corrosion resistance, making it a suitable choice for heat shield applications in various appliances.

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into dilute sulphuric acid?

- it firstly etches off the oxide on the surface of aluminum, and then reacts with aluminum, generating bubble.

- Q: What are the different types of alloys used for aluminum sheets?

- There are various types of alloys used for aluminum sheets, including 1xxx, 3xxx, 5xxx, and 6xxx series. Each alloy has unique properties and characteristics, making them suitable for different applications. The 1xxx series alloys are pure aluminum, while the 3xxx series alloys contain manganese and exhibit good formability. The 5xxx series alloys have magnesium as the primary alloying element and offer excellent corrosion resistance. Lastly, the 6xxx series alloys are known for their combination of strength, formability, and weldability, with magnesium and silicon as their main alloying elements.

- Q: What types of aluminum sheets are recommended for outdoor use due to their properties?

- <p>Yes, there are specific types of aluminum sheets designed for exterior applications. These include aluminum sheets with protective coatings such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a PVDF (Polyvinylidene Fluoride) coating, such as Kynar 500, are highly suitable for exterior use due to their excellent durability and resistance to UV rays, chemicals, and scratches. These coatings help maintain the aluminum's appearance and integrity over time, making them ideal for outdoor applications where exposure to the elements is a concern.</p>

- Q: What is the typical yield strength of aluminum sheets?

- The yield strength of aluminum sheets can differ based on the grade and thickness of the sheet. On average, the yield strength of aluminum sheets falls within the range of 30 to 100 MPa (megapascals). It should be noted that this is a broad range, and specific aluminum alloys may exhibit higher or lower yield strengths. Moreover, factors like heat treatment and processing conditions can also impact the yield strength.

- Q: Are aluminum sheets suitable for electronic components?

- Yes, aluminum sheets are suitable for electronic components. Aluminum is commonly used in the production of electronic components due to its excellent conductive properties, lightweight nature, and high thermal conductivity. It is often utilized in circuit boards, heat sinks, and enclosures for electronic devices.

- Q: What are the advantages of using aluminum sheets in the furniture industry?

- Aluminum sheets have numerous benefits when utilized in the furniture industry. To begin with, their lightweight composition makes them easy to transport and install, reducing the overall weight of furniture and simplifying assembly or rearrangement. Moreover, their lightweight nature allows for increased design flexibility, enabling manufacturers to create intricate and distinctive furniture pieces. Additionally, aluminum sheets possess exceptional durability and corrosion resistance. Unlike materials such as wood or steel, aluminum does not rust or deteriorate over time, making it suitable for both indoor and outdoor furniture. This durability ensures that furniture constructed from aluminum sheets has a longer lifespan, reducing the need for frequent replacements. Furthermore, aluminum sheets possess high malleability, facilitating effortless shaping and customization. This design flexibility empowers furniture manufacturers to fabricate pieces with intricate patterns, curves, and contours. Aluminum sheets can be easily molded into various shapes and sizes, providing limitless possibilities for creativity and innovation in furniture design. Moreover, aluminum sheets require minimal maintenance. They are easy to clean and necessitate minimal upkeep, saving time and effort for both manufacturers and consumers. Consequently, aluminum sheets are an ideal choice for furniture in high-traffic areas or public spaces where regular cleaning is necessary. Furthermore, aluminum sheets contribute to environmental sustainability. Aluminum is a highly recyclable material, allowing furniture made from aluminum sheets to be easily recycled at the end of its life cycle. This reduces the environmental impact and promotes sustainability within the furniture industry. Lastly, aluminum sheets possess excellent thermal conductivity. Furniture constructed from aluminum sheets can efficiently absorb and dissipate heat, providing comfort to users. For applications such as outdoor furniture or items exposed to sunlight, aluminum sheets can prevent overheating and maintain a comfortable temperature. In conclusion, the advantages of using aluminum sheets in the furniture industry encompass their lightweight composition, durability, malleability, low maintenance, environmental friendliness, and excellent thermal conductivity. These properties have made aluminum sheets a popular choice among furniture manufacturers, enabling them to produce high-quality, innovative, and long-lasting furniture pieces.

Send your message to us

1.8mm Brushed Coated Aluminium Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords