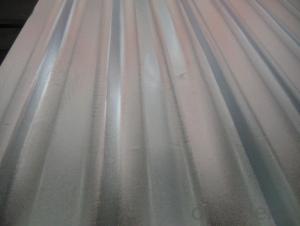

Galvalume Corrugated Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

We specialize in manufacturing galvanized steel coil, galvalume steel coil, prepainted steel coil and galvanized corrugated sheets.

Nowadays our company has grown up to a collectivized company . We are grateful to the cooperation partner who`s grown with us all the way. We hope we could make more friends from all over the world. Under the joint efforts of both sides we believe that we will continue to achieve win-win results based on mutual trust and mutual support.

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Type: | Technique: | Surface Treatment: | |||

| Application: | Special Use: | Width: | |||

| Length: | Based Material: | Material: | |||

| Zinc Coated: | Spangle: | Shape: | |||

| Galvanized Type: | Business: | Payment Terms: | |||

| Packaging: | Delivery Detail: |

Packaging & Delivery

| Packaging Detail: | Fully seaworthy export packing with paper tube Each coil is wrapped in water-proof paper. |

| Delivery Detail: | about 15 days after the deposit if the quantity below 500 ton. |

Specifications

Corrugated gi/gl/ppgi Sheet

1.Thickness: 0.13mm-1.0mm

2.Width:750mm-1250mm

3. z40-z150g/m2

4.ISO 2000,SGS

- Q: Can steel sheets be laminated with other materials?

- Yes, steel sheets can be laminated with other materials. Lamination is a process where multiple layers of materials are bonded together to create a composite structure. Steel sheets can be laminated with various materials such as plastics, polymers, wood, or other metals, depending on the desired properties and application requirements. This lamination process enhances the strength, durability, and overall performance of the steel sheets.

- Q: Are the steel sheets recyclable?

- Indeed, steel sheets possess recyclability. Owing to their remarkable recycling rate and convenient processing, steel stands as one of the extensively recycled materials worldwide. Upon reaching their lifespan's culmination, steel sheets undergo collection, sorting, and transportation to recycling facilities, where they undergo the melting process and are subsequently reshaped into fresh steel commodities. By recycling steel sheets, not only are natural resources conserved and energy consumption reduced, but waste is also diminished, thereby mitigating environmental consequences.

- Q: Why is the water stop steel plate placed in the middle of the wall?

- Of course not. It's in the middle of the perfectly accurate, roughly the middle of the wall. General concrete wall, if there is double layer steel bar, placed in the middle of the two layer of steel bar, when placed with short steel welded fixed on the steel skeleton, pay attention to water stop steel plate, not with the structure steel affixed together.

- Q: What are the common applications of cold-rolled steel sheets?

- Cold-rolled steel sheets are commonly used in various industries for applications such as automotive components, appliances, construction materials, machinery, and electrical equipment.

- Q: Can steel sheets be used for artistic or sculptural projects?

- Yes, steel sheets can be used for artistic or sculptural projects. Steel sheets offer durability, strength, and versatility, making them a popular choice for artists and sculptors. They can be cut, shaped, welded, and manipulated to create various forms and designs, allowing artists to unleash their creativity and bring their visions to life. Additionally, steel sheets can be finished with different coatings or patinas to enhance their aesthetic appeal and protect them from corrosion.

- Q: Can steel sheets be used for construction equipment?

- Yes, steel sheets can be used for construction equipment. Steel is a versatile and durable material that is commonly used in the construction industry for various applications, including equipment fabrication. Steel sheets can be shaped, welded, and formed into different components and structures needed for construction equipment, such as bulldozers, cranes, excavators, and dump trucks. Steel's high strength-to-weight ratio makes it suitable for heavy-duty equipment, providing the necessary strength and stability while keeping the weight manageable. Additionally, steel is resistant to corrosion, which is crucial for construction equipment exposed to harsh environmental conditions. Overall, steel sheets are a popular choice for construction equipment due to their strength, durability, and versatility.

- Q: What is the weight of a standard steel sheet?

- The weight of a standard steel sheet can vary depending on its size and thickness. However, an average steel sheet typically weighs around 30 to 40 pounds per square foot.

- Q: Can steel sheets be used in food-grade applications?

- Yes, steel sheets can be used in food-grade applications. Stainless steel sheets, in particular, are commonly used in food processing and storage as they are resistant to corrosion, easy to clean, and do not react with food.

- Q: How do steel sheets compare to stainless steel sheets in terms of corrosion resistance?

- Steel sheets and stainless steel sheets differ significantly in terms of corrosion resistance. While steel sheets are prone to corrosion due to their high carbon content, stainless steel sheets are specifically designed to resist corrosion. This is achieved by adding chromium to the alloy, which forms a protective oxide layer on the surface, preventing rust and corrosion. Therefore, stainless steel sheets offer superior corrosion resistance compared to regular steel sheets.

- Q: Can steel sheets be used in aerospace applications?

- Yes, steel sheets can be used in aerospace applications. However, their usage is limited due to factors such as weight and strength requirements.

Send your message to us

Galvalume Corrugated Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords