GI steel sheet GI steel sheet GI steel sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

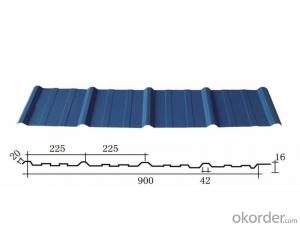

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC | Thickness: | 0.12~1.5mm |

| Place of Origin: |

| Brand Name: |

| Model Number: | 0.12-1.2mm*1250mm or under |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Galvanized |

| Application: | build/appliance/car | Special Use: | Wear Resistant Steel | Width: | 1000mm, 1200mm, 1219mm, 1250mm. |

| Length: | 200~1000m/ton | Base metal: | hot dipped galvanized steel | Coil ID: | 508mm/610mm |

| Feature: | anti-erosion |

Packaging & Delivery

| Packaging Detail: | 4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection |

| Delivery Detail: | after payment for 30days |

Specifications

1. Entity factory

2. Galvanization or hot dip

3. (0.12-1.5)*1250mm or under

4.SGCC/JIS/G3302/DX51D

5.A competitive price

Galvanized Steel

| Company | |

| Product | Hot dipped galvanized steel coil |

| Standard | ASTM A653/JIS G3302/GB/T2518-2004 |

| Grade | SGCC,SPCC,DX51D,SGCH |

| Thickness | 0.17mm-0.80mm |

| Width | 914/1000/1219/1220/1250mm or as your requirement |

| Technique | Cold rolled,hot dipped galvanized,chromated,unoiled, TENSION LEVELLERT SKIN PASS |

| Applaication | Structure use,roofing,profile,commercial use,household appliance,industry,etc. |

| Type | Steel coil |

| Zinc coating | 40-180g/m2 |

| Coil weight | 4-8metric tons |

| Coil ID | 508/610mm |

| FOB price | US$700-900/metric ton |

| Port | Qingdao/Tianjin,China |

| MOQ | 25metric tons |

| Supply ability | 17,000metric tons per month or more |

| Payment terms | T/T,L/C |

| Delivery time | Within 20days upon receipt of payment |

| Packing detail | Wrapped by plastic film and waterproof paper,then fastened on wooden pallet.Shipped by 20'GP containers. |

- Q: Do the steel sheets come in different finishes?

- Indeed, steel sheets are available in various finishes. Among the most frequently used finishes for steel sheets are brushed, polished, matte, satin, and textured. These finishes are attained through diverse methods, including grinding, sanding, or applying chemical treatments. The preferred finish is contingent upon the desired visual appeal, functionality, and intended purpose of the steel sheet. Diverse finishes can offer distinct degrees of luster, sleekness, or texture, thereby enabling customization and adaptability across a range of applications, including architectural, automotive, and industrial sectors.

- Q: What are the standard dimensions for steel sheets?

- The standard dimensions for steel sheets vary depending on the specific type and grade of steel, but commonly used dimensions include 4 feet by 8 feet, 4 feet by 10 feet, and 5 feet by 10 feet.

- Q: What is the average thickness tolerance for steel sheets?

- The average thickness tolerance for steel sheets varies depending on the specific type of steel and the industry standards. However, in general, the average thickness tolerance for steel sheets is typically around +/- 0.005 to 0.010 inches.

- Q: What is the maximum temperature resistance of steel sheets?

- The maximum temperature resistance of steel sheets is dependent on the specific type of steel and its composition. Stainless steel, in general, exhibits good heat resistance and can endure temperatures up to approximately 1200 degrees Celsius (2200 degrees Fahrenheit) while maintaining its strength and structural integrity. Conversely, high carbon steels can tolerate temperatures up to around 900 degrees Celsius (1650 degrees Fahrenheit) before experiencing a decline in their mechanical properties. It should be noted that these temperature limits are approximate and subject to variation based on factors such as exposure duration, the presence of other elements or impurities in the steel, and the specific application of the steel sheets. Consequently, it is always prudent to refer to the manufacturer's specifications or conduct further research to ascertain the precise maximum temperature resistance of a specific type of steel sheet.

- Q: Can steel sheets be perforated?

- Yes, steel sheets can be perforated. Perforation is the process of creating small holes or patterns in a material, and steel sheets can be perforated to enhance their functionality or aesthetics.

- Q: What are the bending and forming capabilities of steel sheets?

- Steel sheets have excellent bending and forming capabilities due to their inherent strength and malleability. They can be easily shaped into various forms, such as curves, angles, and complex geometries, through processes like bending, rolling, and stamping. This versatility makes steel sheets widely used in industries such as construction, automotive, and manufacturing.

- Q: How do you calculate the yield strength of a steel sheet?

- In order to determine the yield strength of a steel sheet, it is necessary to carry out a tensile test, which involves subjecting a sample of the steel sheet to stretching until it fractures. During this test, the stress and strain applied to the sample are measured. The yield strength denotes the point at which the material starts to deform plastically, meaning that it no longer returns to its original shape after the stress is removed. This mechanical property is of great importance as it indicates the maximum stress that the material can endure without undergoing permanent deformation. Throughout the tensile test, the stress applied to the steel sheet is measured as the strain on the sample is gradually increased. Stress is determined by dividing the force exerted on the sample by its initial cross-sectional area. Strain is calculated by dividing the change in length of the sample by its original length. The yield strength is defined as the stress at which a specific amount of permanent deformation occurs, typically 0.2% strain or 0.2% offset. In other words, the yield strength is the stress required to initiate a 0.2% alteration in the length of the sample. Once the stress-strain data is obtained from the tensile test, it is possible to plot a stress-strain curve. By locating the point on the curve where the stress corresponding to the specified amount of strain is reached, the yield strength can be determined. To summarize, to calculate the yield strength of a steel sheet, it is necessary to conduct a tensile test and measure the stress and strain applied to the sample. The yield strength is then determined by identifying the point on the stress-strain curve where a specific amount of permanent deformation occurs, indicating the maximum stress the steel sheet can withstand.

- Q: What are the driving methods for steel sheet piles?

- The construction of steel sheet pile mainly consists of mechanical hand, crawler crane, vibratory hammer and static pile driving machine.

- Q: What are the different grades of steel sheets?

- There are several different grades of steel sheets, which are classified based on their chemical composition, strength, and other properties. Some common grades include mild steel, stainless steel, high-strength low-alloy (HSLA) steel, and galvanized steel. Each grade has specific characteristics that make it suitable for different applications and industries.

- Q: Can steel sheets be used for manufacturing industrial equipment?

- Indeed, the utilization of steel sheets for the production of industrial equipment is possible. Due to its robustness, longevity, and resistance to deterioration, steel is a multifaceted and extensively employed substance in various industries. When it comes to the manufacturing of industrial equipment, steel sheets can be effortlessly shaped, cut, and formed into diverse components. These components are essential for the creation of machinery, tools, storage tanks, conveyors, and structural supports. Furthermore, steel sheets possess exceptional load-bearing capacity, rendering them suitable for demanding applications in sectors like construction, automotive, aerospace, energy, and manufacturing. Moreover, steel sheets can be subjected to treatments or coatings to augment their properties, such as enhancing their resistance to heat, chemicals, or wear. In conclusion, due to their durability, adaptability, and dependability, steel sheets are an immensely popular choice for the manufacturing of industrial equipment.

Send your message to us

GI steel sheet GI steel sheet GI steel sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords