ZYTF PRE-PAINTED ALUZINC STEEL galvanized H type steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 8000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

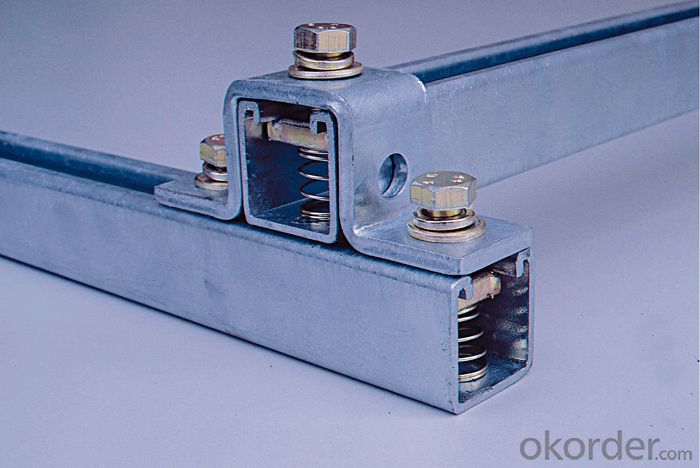

No welding and drilling. Can be conveniently Cagai adjustment, repeated use, wasteminimization.

The professional good coordination, improve indoor space elevation

Has good compatibility, the professional can share a hanger; make full use of space, can make each professional bundles can be good coordination.

- force, stable and reliable

Design and construction of atlas and complete, all the stress components -- type steel and fastener (with locking serrations) can realize the assembly components of a rigid mating,connecting without displacement, no order adjustment, accurate positioning. Shock and vibration, enhance the shear resistance capacity of bracket nodes.

And tracking services, real-time guidance, doubts on the construction site

Technical personnel at the scene guidance, FAQ, do mechanics analysis in real-time tomeet in the construction of the special support and hanger, and the coordination of various professional bundle

And fast installation, short construction period

The installation speed is 6~8 times of traditional practices, in reducing the cost ofmanufacture and installation of 1/2. All professions and trades cross operation, improve work efficiency, shorten the construction period.

And long service life, convenient maintenance

The use of the environment, according to special requirements of customers, provide different process materials are electric galvanized (Leng Duxin), hot dip galvanized andgalvanized coating powder (spray)

Quasi - materials budget

Ensure the products for the standardization of semi-finished products, model identificationwith clear, standardized management, materials and the fittings on the waste and loss ofrare.

And excellent quality assurance

With ISO9000, ISO9002 standard, ensure the stability of the whole system integrity andhanger.

Good generality

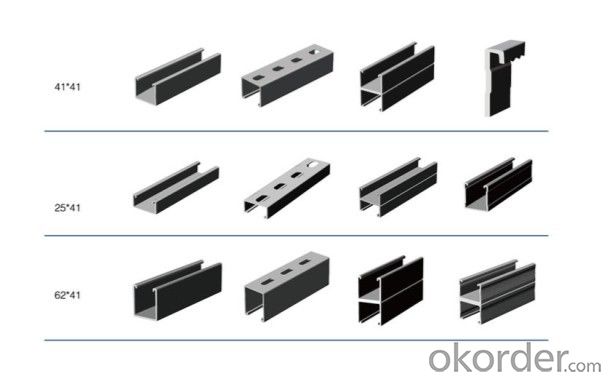

And the combination of standard component types of rich, available options. Ensure all kinds of support under different conditions, simplicity, applicability and flexibility.

And environmental protection

Construction without welding and flame, will not impact on the environment and office.

Our factory has ten fully automatic and semi automatic cold bending production line eight,has its own development team, the independent development of mold design to meet the various needs of customers. Product appearance, size precision, reasonable design,convenient use saves the massive manpower and physical for customers, reducing the cost, the products are widely used in the construction industry, automobile manufacturing,solar power generation, machinery manufacturing, power transmission tower, bridge, shipmilitary aviation industry, railway and highway construction, machine room equipmentcontainer, mineral support etc.. The best-selling products, well received by customers. This is a company won the trust of customers, has broad prospects for development of theenterprise.

Z type steel main points: equilateral Z type steel, galvanized Z type steel, solar stent type Zsteel, the major and medium small type Z steel, Z shaped steel purlin, template supportoverlapped Z type steel Z steel, Z steel, such as automobile profiles, the above specifications for factory main products, such as shape, specifications, drawings can betransfer to my company.

Specifications of Z steel can be used: (26-400) X (25-200) X (9-20) X (0.5-16)

Bottom width X high side X small side wall thickness of X = can be customized

- Q: What are the design considerations for steel research and development centers?

- When it comes to designing steel research and development centers, there are several important factors that must be taken into account in order to ensure optimal functionality and efficiency. These factors include: 1. Flexibility is key. It is essential to design steel research and development centers with a layout that can be easily reconfigured. This is important because research requirements and equipment may change over time. The ability to adapt the layout to accommodate new technologies or research projects is crucial for the long-term success of the center. 2. Safety and security are of utmost importance. Given the nature of steel research, it is essential that the facility meets all necessary safety standards and regulations. This includes implementing fire protection measures, emergency exits, and proper ventilation. Additionally, it is important to have adequate security systems in place to protect valuable research data and equipment. 3. Specialized equipment is a requirement. Steel research and development centers need specialized equipment to carry out various tests and experiments. The design of the center should take into consideration the installation of this equipment, ensuring proper spacing, accessibility, and infrastructure support. It is also important to design the layout in a way that allows for easy maintenance and upgrades of the equipment. 4. Collaboration spaces are essential. Collaboration is a vital aspect of research and development centers. The design should incorporate spaces such as meeting rooms, conference areas, and breakout spaces to encourage interaction and knowledge sharing among researchers, engineers, and other stakeholders. These spaces should be designed to foster creativity, brainstorming, and idea generation. 5. Enhancing workflow is crucial. The design of the center should facilitate a smooth workflow in order to enhance productivity and efficiency. This includes optimizing the flow of materials, minimizing travel distances between different areas, and ensuring the logical sequencing of research processes. A well-planned layout can greatly improve the overall efficiency of the research and development center. 6. Energy efficiency is a must. Considering the energy-intensive nature of steel research, it is crucial to design the center with energy efficiency in mind. This can be achieved by incorporating energy-efficient lighting systems, HVAC systems, and insulation. It may also be worth considering the use of renewable energy sources, such as solar panels, to reduce the environmental impact of the facility. 7. Future expansion should be considered. The design of the steel research and development center should take into account future growth and expansion. The facility should have the potential to accommodate additional research areas, laboratories, or offices without causing significant disruption to ongoing operations. This allows for scalability and ensures that the center can adapt to future research needs. In conclusion, the design considerations for steel research and development centers include flexibility, safety and security, specialized equipment, collaboration spaces, efficient workflow, energy efficiency, and future expansion. By taking these factors into account during the design process, a well-equipped and functional research center can be created to drive innovation and advancements in the steel industry.

- Q: How are steel structures used in the construction of water parks?

- Steel structures are widely used in the construction of water parks due to their strength, durability, and versatility. These structures provide the necessary support for various elements such as water slides, wave pools, and splash pads. Steel beams and columns are used to create the framework of the park, ensuring the stability and safety of the entire structure. Additionally, steel is resistant to corrosion, which is crucial in a water park environment where there is constant exposure to water and chemicals. Overall, steel structures play a vital role in constructing water parks, providing a solid foundation for the thrilling and enjoyable experiences they offer.

- Q: How do steel structures provide efficient use of space?

- Efficient utilization of space is a primary advantage of steel structures, owing to their strength and durability. Steel is renowned for its high strength-to-weight ratio, enabling it to support heavy loads while minimizing material requirements. Consequently, large and tall structures can be constructed without the need for excessive space. Furthermore, steel structures can be designed with extended spans, necessitating fewer columns or supports. This results in open and flexible floor plans, facilitating efficient space utilization. Additionally, steel enables the creation of vast clear spans, eliminating obstructions within the structure and maximizing usable area. Moreover, steel structures can be prefabricated off-site and subsequently assembled on-site. This reduces construction time and minimizes disruption to the surrounding environment. The capacity for prefabricating steel components also ensures precise and accurate construction, guaranteeing effective utilization of every inch of space. Lastly, steel structures possess the advantage of easy modification or expansion. The flexibility of steel allows for seamless integration of additional floors or extensions, accommodating changing needs or requirements. This adaptability ensures efficient long-term space utilization. In conclusion, steel structures offer efficient space utilization through their strength, durability, capacity for extended and clear spans, prefabrication capabilities, and flexibility for future modifications.

- Q: How are steel structures designed for blast-induced vibrations?

- Steel structures are designed for blast-induced vibrations by considering the dynamic response of the structure to the blast load. This involves analyzing the blast loading characteristics, such as the magnitude, duration, and frequency content, and then designing the structure to withstand these loads. Various design techniques, such as dynamic analysis, material selection, and structural detailing, are employed to ensure the steel structure can effectively absorb and dissipate the energy generated by the blast, thus minimizing the impact of vibrations on the structure and its occupants.

- Q: What is the rib of steel structure?

- Strip reinforcement for ensuring local stability of member and transfer of force.Action: a: forces the transverse force on the beam to the web of the beam to make it the shear of the beam;B: passes the shear of the web beam to the support of the beam.What the upstairs says is: support stiffener

- Q: What is the role of welding in steel structure fabrication?

- The role of welding in steel structure fabrication is crucial as it is the primary method used to join individual steel components together, creating a strong and durable structure. Welding ensures the structural integrity of the steel framework, allowing it to withstand various external forces and loads. Additionally, welding allows for the customization and flexibility in design, making it possible to create complex and intricate steel structures. Overall, welding plays a vital role in the fabrication process, ensuring the safety, strength, and functionality of steel structures.

- Q: How does the design of steel structures differ for industrial applications?

- The design of steel structures for industrial applications differs in several key aspects compared to other types of structures. The primary focus is on the strength, durability, and functionality required to meet the specific demands of industrial environments. One of the main differences is the larger scale and heavier loads that industrial structures need to support. Industrial facilities often house heavy machinery, equipment, and materials, which exert significant loads on the structure. Therefore, the design of steel structures for industrial applications must account for these loads and ensure that the structure can withstand them without any compromise in its integrity. Another crucial factor in the design of steel structures for industrial applications is the consideration of dynamic loads and vibrations. Industrial facilities often involve the operation of heavy machinery, which can generate vibrations and dynamic forces that need to be absorbed by the structure. The design must incorporate measures to mitigate these vibrations and ensure the overall stability and safety of the structure. Moreover, the design of steel structures for industrial applications must also address the specific needs of the industry in terms of functionality and practicality. Industrial facilities typically require large open spaces, high ceilings, and wide column spacing to accommodate storage, production lines, and large machinery. The design must provide flexibility for layout changes and expansion, ensuring that the structure can adapt to evolving industrial needs. Additionally, industrial environments often expose steel structures to harsh conditions such as extreme temperatures, corrosive substances, and potential impact from heavy objects. Therefore, the design must incorporate protective measures such as specialized coatings and materials that can withstand these conditions and prevent corrosion or other forms of deterioration. Lastly, the design of steel structures for industrial applications must also consider the economic aspect. Industrial facilities are long-term investments, and the design should optimize material usage, construction costs, and maintenance requirements while ensuring the required structural integrity and functionality. In summary, the design of steel structures for industrial applications differs by focusing on strength, durability, functionality, and practicality. It must account for larger scale and heavier loads, address dynamic loads and vibrations, provide flexibility for layout changes, protect against harsh conditions, and optimize economic considerations.

- Q: What are the acoustic properties of steel structures?

- Steel structures have excellent acoustic properties due to their high density and stiffness. They possess low sound transmission, meaning they effectively block the passage of sound waves from one area to another. Additionally, steel structures have a high sound reflection capability, which allows for better sound clarity and amplification within enclosed spaces.

- Q: What are the considerations for steel structure design in hurricane-prone areas?

- When designing steel structures in hurricane-prone areas, several considerations must be taken into account. Firstly, the structure should be designed to withstand high wind speeds and the associated uplift forces. This can be achieved by incorporating wind-resistant features such as appropriate bracing systems, strong connections, and adequate anchorage to the foundation. Additionally, the design should account for potential debris impact, as hurricanes often involve the flying of objects that can damage the structure. Reinforcing the exterior walls and windows with impact-resistant materials can help mitigate this risk. Furthermore, the structure should be designed to minimize wind-induced vibrations, which can cause discomfort and potential damage. This can be achieved by using appropriate damping techniques and ensuring the structure's natural frequency does not coincide with the dominant wind load frequency. Overall, the design for steel structures in hurricane-prone areas should prioritize robustness, resistance to wind loads, and resilience against potential impacts, ensuring the safety and durability of the structure in the face of extreme weather conditions.

- Q: What is the difference between a steel structure and a steel warehouse?

- A steel structure refers to a construction made entirely or primarily out of steel, which can include buildings, bridges, or other infrastructure. On the other hand, a steel warehouse specifically refers to a building designed and constructed for storing goods or materials, typically made out of steel for its durability and strength. In summary, a steel structure is a broader term encompassing various steel constructions, while a steel warehouse is a specific type of steel structure designed for storage purposes.

Send your message to us

ZYTF PRE-PAINTED ALUZINC STEEL galvanized H type steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 8000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords