HF PRE-PAINTED GALVANIZED Hshaped steel purlin

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 8000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The professional good coordination, improve indoor space elevation

Has good compatibility, the professional can share a hanger; make full use of space, can make each professional bundles can be good coordination.

- force, stable and reliable

Design and construction of atlas and complete, all the stress components -- type steel and fastener (with locking serrations) can realize the assembly components of a rigid mating,connecting without displacement, no order adjustment, accurate positioning. Shock and vibration, enhance the shear resistance capacity of bracket nodes.

And tracking services, real-time guidance, doubts on the construction site

Technical personnel at the scene guidance, FAQ, do mechanics analysis in real-time tomeet in the construction of the special support and hanger, and the coordination of various professional bundle

And fast installation, short construction period

The installation speed is 6~8 times of traditional practices, in reducing the cost ofmanufacture and installation of 1/2. All professions and trades cross operation, improve work efficiency, shorten the construction period.

And long service life, convenient maintenance

The use of the environment, according to special requirements of customers, provide different process materials are electric galvanized (Leng Duxin), hot dip galvanized andgalvanized coating powder (spray)

Quasi - materials budget

Ensure the products for the standardization of semi-finished products, model identificationwith clear, standardized management, materials and the fittings on the waste and loss ofrare.

And excellent quality assurance

With ISO9000, ISO9002 standard, ensure the stability of the whole system integrity andhanger.

Good generality

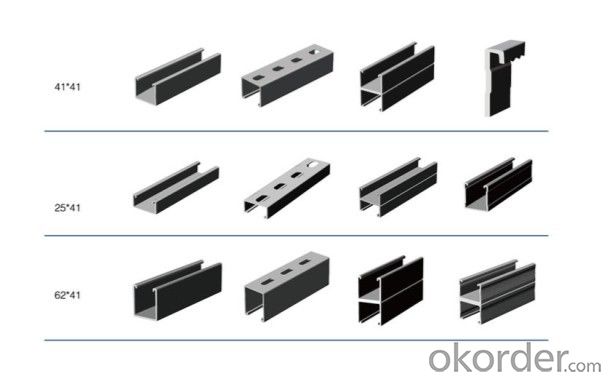

And the combination of standard component types of rich, available options. Ensure all kinds of support under different conditions, simplicity, applicability and flexibility.

And environmental protection

Construction without welding and flame, will not impact on the environment and office.

Our factory has ten fully automatic and semi automatic cold bending production line eight,has its own development team, the independent development of mold design to meet the various needs of customers. Product appearance, size precision, reasonable design,convenient use saves the massive manpower and physical for customers, reducing the cost, the products are widely used in the construction industry, automobile manufacturing,solar power generation, machinery manufacturing, power transmission tower, bridge, shipmilitary aviation industry, railway and highway construction, machine room equipmentcontainer, mineral support etc.. The best-selling products, well received by customers. This is a company won the trust of customers, has broad prospects for development of theenterprise.

Z type steel main points: equilateral Z type steel, galvanized Z type steel, solar stent type Zsteel, the major and medium small type Z steel, Z shaped steel purlin, template supportoverlapped Z type steel Z steel, Z steel, such as automobile profiles, the above specifications for factory main products, such as shape, specifications, drawings can betransfer to my company.

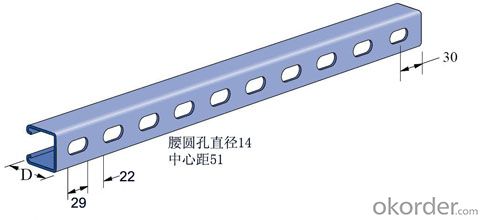

Specifications of Z steel can be used: (26-400) X (25-200) X (9-20) X (0.5-16)

Bottom width X high side X small side wall thickness of X = can be customized

- Q: What is the difference between a steel structure and a steel power plant?

- A steel structure refers to a building or infrastructure that is primarily made of steel as the main structural material. It could be a residential, commercial, or industrial building, a bridge, a stadium, or any other construction where steel is used to provide strength and stability. The primary focus of a steel structure is to provide a safe and reliable framework for the desired purpose, such as housing, offices, or entertainment. On the other hand, a steel power plant specifically refers to a facility that generates electricity using steel components and structures. It is a specialized type of steel structure that is designed and built to house various power generation equipment and systems. Steel power plants are equipped with turbines, generators, boilers, condensers, transformers, and other machinery required for the production of electricity. While both a steel structure and a steel power plant are made of steel, the key difference lies in their purpose and functionality. A steel structure serves as a general construction, providing a durable framework for various types of buildings, while a steel power plant is a specialized facility designed specifically for power generation. The design and construction of a steel power plant are more complex and require specific engineering considerations, such as the integration of power generation equipment, cooling systems, and safety measures. In summary, a steel structure is a generic term for any construction primarily made of steel, serving a wide range of purposes, while a steel power plant is a specific type of steel structure designed solely for the purpose of generating electricity.

- Q: What are some famous steel structures around the world?

- There are several famous steel structures around the world that are recognized for their impressive architectural design, engineering achievements, and cultural significance. Here are a few notable examples: 1. Eiffel Tower, Paris, France: The Eiffel Tower is one of the most recognizable steel structures globally and an iconic symbol of Paris. Designed by Gustave Eiffel, it was completed in 1889 and stood as the tallest man-made structure until the completion of the Chrysler Building in 1930. 2. Empire State Building, New York City, USA: The Empire State Building, completed in 1931, is an iconic skyscraper that showcases the use of steel in its construction. It was the tallest building in the world until the completion of the North Tower of the World Trade Center in 1970. 3. Sydney Opera House, Sydney, Australia: This world-renowned performing arts center is famous for its unique sail-like design and extensive use of steel. Designed by Danish architect Jørn Utzon, it was completed in 1973 and has become an enduring symbol of Australia. 4. Gateway Arch, St. Louis, USA: The Gateway Arch is an architectural marvel and a symbol of the American West. Completed in 1965, it stands as the tallest arch in the world and is made entirely of stainless steel. The arch's elegant design is a testament to the advancements in steel construction. 5. Burj Khalifa, Dubai, United Arab Emirates: The Burj Khalifa is the tallest building in the world, reaching a staggering height of 828 meters. Its construction relied heavily on steel and advanced engineering techniques. Completed in 2010, the Burj Khalifa is a masterpiece of modern architecture and a testament to the versatility and strength of steel. 6. The Bird's Nest Stadium, Beijing, China: Also known as the Beijing National Stadium, this iconic structure was built for the 2008 Summer Olympics. Designed by Swiss architects Herzog & de Meuron, it features a distinctive lattice-like steel structure, making it one of the most unique and visually striking stadiums in the world. These famous steel structures showcase the versatility, strength, and beauty of steel in construction and have become iconic symbols of their respective cities and countries. They stand as testament to human ingenuity and engineering achievements.

- Q: What are the different types of steel coatings used in structures?

- There are several different types of steel coatings used in structures, including galvanized coatings, epoxy coatings, powder coatings, and metallic coatings. Galvanized coatings involve applying a layer of zinc to the steel, providing protection against corrosion. Epoxy coatings are a type of paint that is applied to the steel surface, offering resistance to chemicals, abrasion, and corrosion. Powder coatings involve electrostatically applying a dry powder to the steel, which is then cured under heat to form a hard, durable finish. Metallic coatings, such as aluminum or zinc, are applied to the steel through a process like galvanization, providing both corrosion resistance and aesthetic appeal.

- Q: How are steel structures used in theme parks and water parks?

- Steel structures are widely used in theme parks and water parks due to their strength, durability, and versatility. They are utilized for various purposes, including the construction of roller coasters, water slides, observation towers, and other attractions. Steel provides the necessary structural support and stability required to withstand the dynamic forces and loads experienced in these amusement park environments. Additionally, steel's ability to be fabricated into complex shapes allows for creative and visually stunning designs, enhancing the overall experience for park visitors.

- Q: What are the factors that affect the aesthetics and visual appeal of a steel structure?

- There are several factors that influence the aesthetics and visual appeal of a steel structure. Firstly, the design and architectural elements incorporated into the structure play a significant role. The shape, form, and proportions of the steel components can greatly impact the overall visual appeal. The choice of materials and finishes also contribute to the aesthetics. The type of steel used, its color, texture, and surface treatment can all influence the visual appeal. Additionally, the integration of other materials such as glass, concrete, or wood can enhance the overall aesthetic value. The surrounding environment and context also affect the visual appeal of a steel structure. The relationship between the structure and its surroundings, whether it blends harmoniously or creates a striking contrast, can greatly impact its aesthetics. Furthermore, the quality of craftsmanship and detailing is crucial in determining the attractiveness of a steel structure. Precise fabrication, careful assembly, and attention to small details contribute to the overall visual appeal. Lastly, the lighting and how it interacts with the structure can significantly enhance its aesthetics. Utilizing natural or artificial lighting to highlight specific features or create dramatic effects can further enhance the visual appeal of a steel structure. In summary, the factors that affect the aesthetics and visual appeal of a steel structure include its design, materials and finishes, context, craftsmanship, and lighting.

- Q: What are the considerations when designing steel structures for museums and cultural centers?

- When designing steel structures for museums and cultural centers, several considerations need to be taken into account. First and foremost, the structural integrity and safety of the building must be ensured to protect the valuable artifacts and visitors. The design should accommodate for the weight and size requirements of the exhibits, as well as any specialized storage or display needs. Aesthetics and architectural vision are also crucial considerations. The steel structure should complement the overall design concept of the museum or cultural center, while allowing for flexibility in space utilization and future modifications. The choice of materials, finishes, and detailing should align with the desired aesthetic and cultural context, creating a visually appealing and harmonious environment. Sustainability and energy efficiency should be incorporated into the design to minimize the environmental impact and operational costs. The use of sustainable materials and efficient building systems, such as natural lighting and ventilation, can help reduce energy consumption and promote a greener approach. Moreover, the functionality and accessibility of the space should be carefully planned. The layout and arrangement of the steel structure should facilitate visitor circulation, provide adequate spaces for exhibitions, galleries, and educational areas, and ensure compliance with accessibility standards for people with disabilities. Lastly, considering the specific requirements of museums and cultural centers, the design should account for factors such as climate control, security, and acoustic considerations. Proper temperature and humidity control, advanced security systems, and appropriate acoustic treatments are essential to preserve the exhibits, ensure visitor comfort, and protect the cultural heritage. Overall, a successful design for steel structures in museums and cultural centers requires a holistic approach that balances structural integrity, aesthetics, sustainability, functionality, and the specific needs of preserving and showcasing cultural artifacts.

- Q: How are steel structures used in automotive manufacturing plants?

- Steel structures are widely used in automotive manufacturing plants for various purposes. One of the key applications of steel structures in automotive manufacturing plants is in the construction of the factory buildings and production facilities. Steel, being a versatile and durable material, provides a strong and stable framework for these structures, ensuring the safety and stability of the entire facility. Steel structures are also used in the assembly lines and production equipment of automotive manufacturing plants. These structures provide a solid foundation and support for the heavy machinery and equipment used in the manufacturing process. The high load-bearing capacity of steel allows for the efficient and smooth operation of these machines, contributing to the overall productivity and efficiency of the plant. Moreover, steel structures are also utilized in the storage and logistics areas of automotive manufacturing plants. Steel warehouses and storage facilities are commonly used to store raw materials, components, and finished products. The strength and durability of steel structures ensure the protection of these valuable assets from environmental factors such as weather and theft. In addition, steel structures are used in the construction of maintenance and repair facilities within automotive manufacturing plants. These structures provide the necessary infrastructure for the maintenance and servicing of vehicles and equipment, ensuring that they remain in optimal condition. Overall, steel structures play a crucial role in automotive manufacturing plants by providing the necessary infrastructure and support for various operations. From the construction of buildings and production facilities to the assembly lines and storage areas, steel structures offer strength, durability, and efficiency, making them an essential component in the automotive manufacturing industry.

- Q: How much is one ton of steel structure installed?

- If the pipe truss, or grid, to 2000-3000 tons of installation costs, depending on the complexity of the structure and the amount of steel to be fixed.

- Q: How are steel structures designed to resist seismic loads?

- Seismic loads are resisted by steel structures through the incorporation of several key design principles and techniques. The first and foremost consideration is the inherent ductility and strength of steel as a material. Engineers begin by analyzing the seismic hazard in the region where the structure will be constructed. They assess factors such as earthquake magnitude and frequency, local soil conditions, and site-specific ground motion characteristics. This information is critical for determining the appropriate design parameters and loadings. The structural system is then designed to absorb and dissipate seismic energy. This is achieved by implementing various lateral load-resisting systems, including moment frames, braced frames, or shear walls. These systems are strategically placed throughout the structure to ensure overall stability and resistance to lateral forces. Furthermore, the connections between steel members are designed to be both strong and ductile. Special attention is given to beam-to-column connections, which are typically the most critical elements in resisting seismic loads. Different connection types, such as moment connections or eccentrically braced connections, are utilized to enable the structure to effectively transfer forces and deform in a controlled manner during an earthquake. To enhance seismic performance, engineers incorporate redundancy and robustness into the structural design. Redundancy refers to the provision of multiple load paths within the structure, allowing for force redistribution in case of localized damage. Robustness ensures that the structure can withstand unexpected or extreme loading conditions without catastrophic failure. Detailed seismic analysis and simulations are conducted using sophisticated computer models to verify the adequacy of the design. These analyses consider the structure's response to different ground motions and assess its performance under various earthquake scenarios. In conclusion, the design of steel structures to resist seismic loads involves a comprehensive approach that considers the specific characteristics of the seismic hazard, the structural system, the connections, and the overall behavior of the structure. By incorporating these design principles, steel structures can effectively withstand seismic forces and minimize the risk of damage or collapse during an earthquake.

- Q: What documents do steel installers need to have?

- Steel structure installation work requirements: structure; material, surface roughness, tolerances, surface treatment, straightness (or arc) connection; hole deviation, bolt grade; welding method, welding standard, welding materials; tightness requirements

Send your message to us

HF PRE-PAINTED GALVANIZED Hshaped steel purlin

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 8000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords