Pre-painted Hot Dipped Galvanized Steel Coil GI Aluzinc Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Hot Dipped Galvanized Steel Coil GI Aluzinc Steel Coils

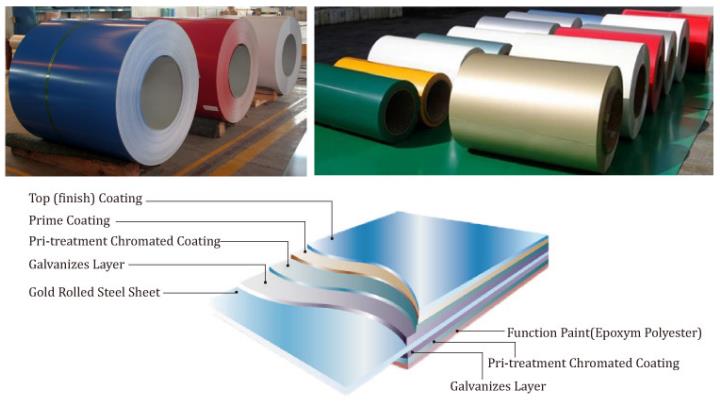

With Gl (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers od color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel.

Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance.

It generally displays superior workability, durability and weather resistance.

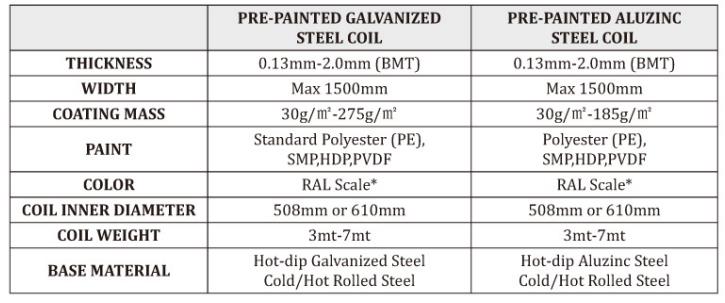

AVAILABLE SPECIFICATION

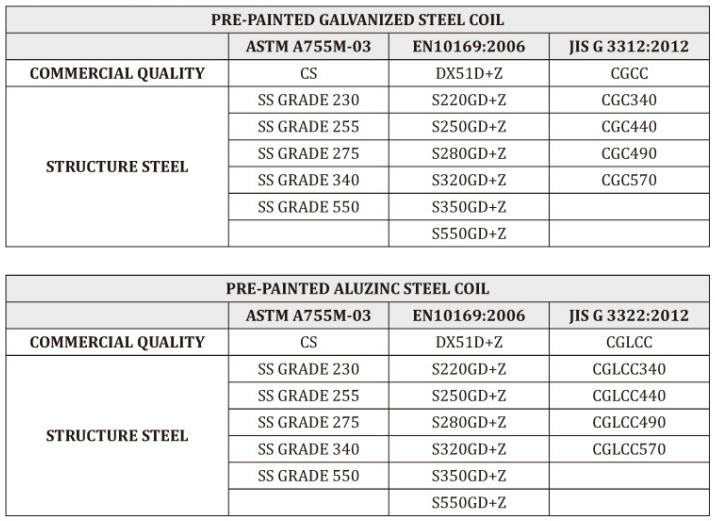

STANDARD & GRADE

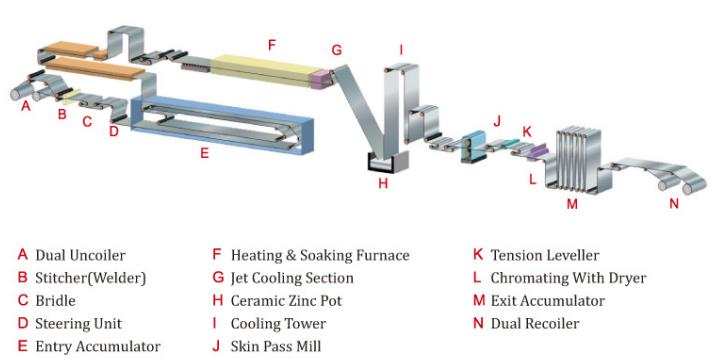

PRODUCTION FLOW

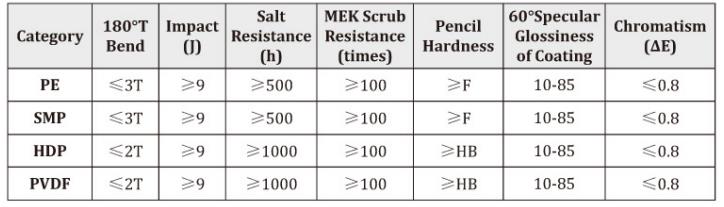

PAINT PROPERTY

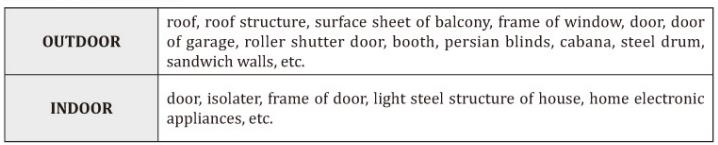

APPLICATION

- Q: I haven't seen Man of Steel yet, but which one do you think was better? (please no spoilers)

- Well, I haven't seen it Man of Steel but I really see it hard to believe that's better than Superman. To me, Superman with Christopher Reeve is the best movie about Superman ever made. When I first saw it I was amazed. Watching Superman flying for the first time, catching Loise and graving that helicopter before it falls... it was awesome! I loved it! The other movies that followed were bad but this one was amazing. I've seen what other actors have made with the character, but I believe Christopher was the best. He was the perfect man, the perfect gentleman and the best superhero ever. I know that this Superman is for the new generations so it will be more 'real' and more 'suffered' or will have more personal issues dealing with his origins and blah blah blah... and I wish him good luck, but honestly? I stick to the original Superman because whenever I see Christopher Reeve flying around the planet as Superman (hanging from wires-no CGI people!) and I hear that characteristic music I just melt and I'm a child once more. So good luck to the new generation, I really hope they like this new guy and new story, but I'm more than fine with the original version, thank you. Hope it helps! ;)

- Q: How are steel coils used in the aerospace industry?

- Steel coils are used in the aerospace industry for various applications such as manufacturing aircraft components, including structural parts, engine components, and landing gear. These coils are often processed and formed into sheets, plates, or other desired shapes to meet the specific requirements of aerospace engineering. The high strength and durability of steel make it an ideal material for withstanding the demanding conditions and stresses experienced by aircraft during flight.

- Q: Is the product of mild steel environmentally friendly? does it produce any emissions?The same question for leather aswell.

- Steel just rusts, it doesn't produce any emissions just sitting there. They even make architectural steel called Corten to rust to a nice patina. If you consider how the steel was made in the first place, a great big NO! Steel making requires massive amounts of electricity plus it gives off some nasty fumes in the liquid state. Leather itself doesn't emit much of anything, but the dyes might. Again though, if you look at how it's made, tanning leather is right up there with steel mills and paper mills for pollution, some of the worst.

- Q: I need help! Please help, I'm in Chemistry, and me and my friend Lucy are making a presentation on steel and iron, so how is steel manufactured? Thank you. :D

- The steel consists of ( Iron ) and another matter... but the popular one is iron+carbon / iron+silver - When iron is smelted from its ore by commercial processes, it contains more carbon than is desirable. To become steel, it must be melted and reprocessed to reduce the carbon to the correct amount, at which point other elements can be added. This liquid is then continuously cast into long slabs or cast into ingots. Approximately 96% of steel is continuously cast, while only 4% is produced as cast steel ingots. The ingots are then heated in a soaking pit and hot rolled into slabs, blooms, or billets. Slabs are hot or cold rolled into sheet metal or plates. Billets are hot or cold rolled into bars, rods, and wire. Blooms are hot or cold rolled into structural steel, such as I-beams and rails. In modern foundries these processes often occur in one assembly line, with ore coming in and finished steel coming out. Sometimes after a steel's final rolling it is heat treated for strength, however this is relatively rare.

- Q: Classify the following in as many ways as possible:stainless steelpureheterogeneous mixturehomogeneous mixturenone of these

- homogeneous mixture

- Q: How do steel coil manufacturers handle product recalls?

- To ensure the safety and satisfaction of their customers, steel coil manufacturers have developed a systematic approach for handling product recalls. The following outlines the steps involved: 1. Identifying the issue: When a potential problem or defect arises in steel coils, manufacturers initiate the recall process. This can be a result of quality control failure, safety concerns, or non-compliance with industry standards. 2. Investigating and evaluating: The manufacturer investigates the root cause of the problem and evaluates its impact on customer safety and satisfaction. They analyze the affected batch or production run to determine the extent of the issue. 3. Notifying customers: Manufacturers promptly inform customers who have purchased the affected steel coils. They utilize various channels, such as direct mail, email, phone calls, or public announcements, to communicate the recall details. This includes specific information about the problem, potential risks, and instructions on how to proceed. 4. Retrieving and replacing: The manufacturer provides instructions on how customers can safely return or dispose of the recalled steel coils. They may offer options for product retrieval, such as direct pick-up or designated drop-off points. In some cases, manufacturers may provide replacement steel coils or reimburse customers for the affected products. 5. Communicating publicly: Steel coil manufacturers issue public statements and notifications to inform the wider market, distributors, and retailers about the recall. This ensures that all stakeholders are aware of the issue and can take appropriate actions. 6. Taking corrective measures: After retrieving the recalled steel coils, manufacturers implement corrective actions to rectify the issue. This may involve improving quality control processes, upgrading manufacturing equipment, or revising product specifications to prevent future recalls. 7. Providing customer support: Throughout the recall process, manufacturers offer customer support to address concerns, questions, or complaints. They establish dedicated hotlines, email addresses, or online portals to assist customers and guide them through the recall process. 8. Ensuring regulatory compliance: Steel coil manufacturers comply with relevant regulatory authorities and standards organizations during the recall process. They work closely with regulatory agencies to provide necessary information, documentation, and updates to meet legal requirements. In conclusion, steel coil manufacturers prioritize customer safety and satisfaction by following a well-defined process for handling product recalls. This includes identifying the issue, investigating, notifying customers, retrieving and replacing products, communicating publicly, implementing corrective actions, providing customer support, and ensuring regulatory compliance. Through these steps, manufacturers aim to rectify the issue, prevent harm, and maintain trust with their customers.

- Q: How do steel coils contribute to the aerospace manufacturing industry?

- The aerospace manufacturing industry heavily relies on steel coils due to their numerous benefits and contributions to overall aircraft production efficiency and quality. To begin with, steel coils are essential in fabricating various structural components of an aircraft, including wings, fuselage, and landing gear. Steel's high strength and durability make it an appropriate material for these critical parts, guaranteeing aircraft safety and reliability. Moreover, steel coils provide the raw material necessary for the precise manufacturing processes required in the aerospace industry, enabling the creation of lightweight yet sturdy structures capable of withstanding the demanding flight conditions. Apart from their structural applications, steel coils also find use in producing smaller aircraft components, such as fasteners, connectors, and brackets that hold different parts of the aircraft together. Steel's exceptional mechanical properties, including resistance to fatigue and corrosion, make it a preferred choice for these components, ensuring their long-term performance and safety. Furthermore, steel coils contribute to the aerospace manufacturing industry by facilitating cost-effective production processes. Steel is widely available in large quantities, making it a cost-efficient material for aircraft manufacturing. Additionally, the ability to produce steel coils in various sizes and thicknesses allows manufacturers to tailor their production to specific aircraft models or design requirements, minimizing waste and optimizing resource allocation. Moreover, steel coils offer inherent recyclability, which aligns with the aerospace industry's increasing focus on sustainability. Recycled steel can be used to produce new coils, reducing the need for raw material extraction and minimizing environmental impact. This circularity in the use of steel coils supports the aerospace industry's efforts towards a more sustainable and environmentally friendly manufacturing process. In conclusion, steel coils play a vital role in the aerospace manufacturing industry by providing the necessary materials for aircraft structures and components. Their strength, durability, cost-effectiveness, and recyclability make them a valuable resource, ensuring the safety, reliability, efficiency, and sustainability of aircraft production.

- Q: How do steel coils impact the overall cost of production?

- Steel coils can have a significant impact on the overall cost of production. The cost of steel coils is a major component in the production process, as they are used as raw materials in various industries such as automotive, construction, and manufacturing. Fluctuations in the price of steel coils can directly affect the cost of production, ultimately influencing the final price of the end product. Additionally, factors such as transportation and storage costs also contribute to the overall impact of steel coils on production costs.

- Q: I plan to buy a bushcraft knife ..The blade made up by damascus steel.My question is ,is damascus steel is very strong ?

- How To Sharpen Damascus Steel

- Q: What are chemical properties of high speed steel? Physical properties?What is high speed steel used for? One interesting fact about high speed steel?

- wikipedia: High speed steel (often abbreviated HSS, sometimes HS) is a material usually used in the manufacture of machine tool bits and other cutters. It is often used in power saw blades and drill bits. It is superior to the older high carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above HRC60) and a high abrasion resistance (generally linked to tungsten content often used in HSS) compared to common carbon and tool steels. see reference for more info .

Send your message to us

Pre-painted Hot Dipped Galvanized Steel Coil GI Aluzinc Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords