ZYC series ZYC180B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

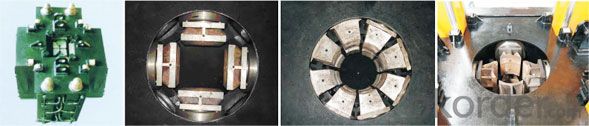

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 180 | suitable pile & specification(mm) | 250-300 ¢300-400 | |

| Max. Piling speed(m/min) | 7.8 | Max. Crane lifting weight(t) | 8 | |

| Piling stroke(m) | 1.6 | Hanging pile length(m) | 12 | |

| Max. Longitudinal pace(m) | 2.4 | Minimum side piling space(mm) | 600 | |

| Max. Transverse pace(m) | 0.5 | Minimum corner piling space(mm) | 1300 | |

| Max. Rise stroke(m) | 1.0 | Hydraulic Pump (Unit × Ml/Turn) | 2×63 + 1×63 | |

| Angle range(°) | 15° | Rated hydraulic system pressure(mpa) | 22.4(16) | |

| Intensity of pressure(tf/m²) | 8.18/12.0 | Weight composition (t) | Machine weight | 80±2 |

| Motor power (Unit × kw) | 2×22 + 1×22 | Angle range(°) Counter weight | 100 | |

| Total weight≥ | 180 | |||

FAQ

To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q: Types of pile drivers

- The market is the piling machine of many kinds, small as you introduced under the following four types: first, drop hammer is a heavy piece of steel, by using the hook lifting winch, after decoupling along the guide frame free fall and piling. Two, hammer hammer by the hammer and the hammer seat, with steam or compressed air as a driving force, a single action and double action two hammer hammer. Single acting piston or cylinder as the hammer to hammer, steam driven hammer up, then let the hammer seat along the guide rod fall and piling. Double acting steam hammer is increased as the plunger cylinder as the hammer to hammer, steam driven hammer up, then drive the downward impact hammer piling. The reciprocating speed is high and the frequency is high, so that the pile can vibrate when penetrating into the stratum, and the friction resistance can be reduced, and the pile driving effect is good. Differential two-way unequal force hammer, the hammer seat light weight, effective impact weight can be relatively stronger and better performance.

- Q: Why levy piling

- Like a chopstick, inserted into the soil is not directly on the ground than in a more stable, the pile is equivalent to the chopsticks into the earth part.

- Q: I've heard that the pile driver's pay is high. I want to study. Also please seniors pointing. Be deeply grateful!

- There's one in the neighborhood. Can find other counterparts to learn, skilled in their own open. However, the piling machine is not stable, but also a team together. And we're going out of town, this month, ten days.

- Q: Mechanical piling machine about how much money?

- Hello, impact pile driver, down fourteen, fifty thousand! I am the engine hand. Contact me if you need me! I can also give you a staff officer for a rig

- Q: I have been using a common type of 260 fence pile driver, I still feel good with the use of, I heard that the loading barrier, pile driver more cattle I'd like to ask if the loader guardrail is practical? What is the daily piling efficiency? What's the fuel consumption? Please let me know when I've got the trouble. I'll try to buy one if I know the right thing.

- Yes, I haven't bought it yet. But I've seen others use it. We used for engineering machinery factory is Sichuan Hongtu buy loading guardrail piling machines, but we are state-owned enterprises, state-owned enterprises as you know the loading driver caitaiqicu nearly 200 000 a buy is five.

- Q: What are the main types of pile drivers?

- In three, diesel hammer hammer x0d is composed of a cylinder body and a plunger piston which is similar to the working principle and the single cylinder two stroke diesel engine into the cylinder combustion under high temperature and high pressure atomized diesel combustion chamber by injection pressure generated by the detonation driven hammer. Diesel hammer according to its structural form, rod and tube type. Guide rod type diesel hammer for hammer pressure in the plunger seat the pile cap, the cylinder for hammer along two guide rods. The lifting pile, the pile hanging in place pile frame in Longmen, then put the diesel hammer at the top of the pile, the hook will lift down the cylinder, and the cylinder sleeve let off hook falling into the plunger, will be closed in the steam The in cylinder air compression cylinder rocker pin until the pressure continues to fall outside the cylinder pushing hammer seat fuel pump, fuel pump will be injected into the cylinder oil mist, oil mist meet high temperature gas burning immediately above, blasting, explosive shock down make the pile sinking, to the top push the cylinder cylinder to be picked up, to fall along the guide rod, and the beginning of the second cycle. The impact of diesel hammer to hammer cylinder as the base, and directly with the lengthened cylinder wall direction, eliminating the two guide rods, the plunger is movable under the hammer in the cylinder. When the pile. The hammer seat at the lower part of the pile cap pressure at the top of the pile, lifting plunger with a hook, and then down from shock compressed in the cylinder in the closed air.

- Q: What is a loading type road pile driver?

- The emergence of the loader pile driver is a breakthrough in the piling machine industry. It not only improves the efficiency of drilling, but also has the ability to work at night as well as the ability to prevent rain and water. It has longer life, better quality and, of course, more expensive prices. But in general, it's good value for money.Traditional road pile driverThe traditional highway pile driver doesn't have the working conditions at night and rainy day, but the punching efficiency is high, but it is not as good as that of the loading type road pile driver. It looks shabby.

- Q: My family from the building, a three storey, only two and half layer design now, frame structure and prefabricated panels, a total of three half empty, with the inner diameter of the air is piling machine, 30CM in the field, with an average depth of 6 meters, I asked how wide a safe? The master said, "one meter, one. I feel a little too dense."! Ask everybody specially!How many meters can I use if I choose an empty 80CM pile driver? My maximum span is 4 meters, and some are 3 meters and 2 meters. Because the master is how many piles count money, so there is little doubt!

- Under normal circumstances, only in the bottom of the structural column to the base of the force transmission area, piling, three layers of self building (small span), each column at the bottom of the general arrangement of 1-3 piles, but the depth of the pile should be determined according to the local geological conditions.

- Q: How much are the pile and Larson piles of a pile driver?

- Would you like to ask the price of the material or the price of the construction?AskMaterial priceChasing the answerI mainly do Larson steel sheet pile products. Domestic 5000 or so, Japan imports 6450.

- Q: Which brand is better for a small pile driver?

- the configuration of the machine and customer service service, selective highest bid is the best policy, piling machine personal feeling of Shandong Lida Company can, the landlord statements of a school for reference!!

Send your message to us

ZYC series ZYC180B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords