Vibro Ripper (DBL Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Sets watt

- Supply Capability:

- 1000 Sets per Month watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Vibro Ripper (DBL Series)

-Innovative, Reliable Original Vibro Ripper in The World!

-Powerful digging force by special vibration structure

VIBRO RIPPER

(DBL Series )

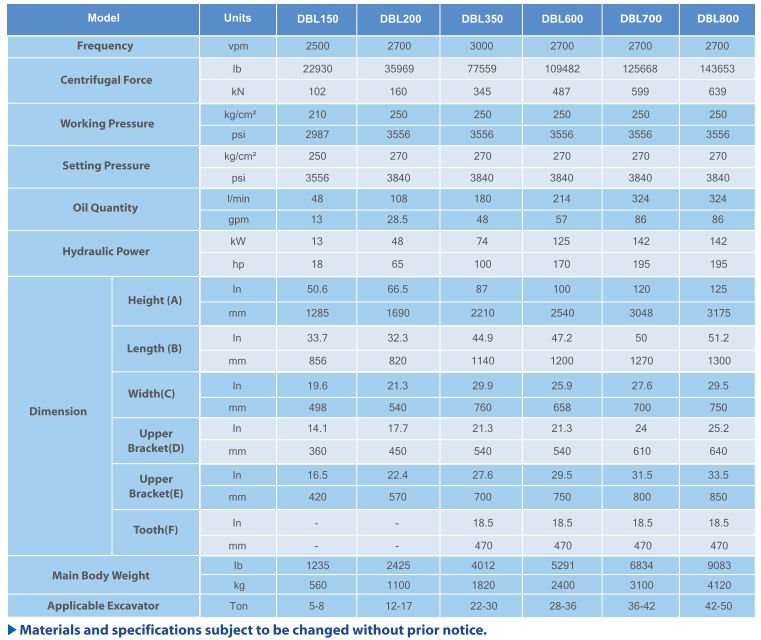

DBL150, DBL200,DBL350,DBL600,DBL700,DBL800

Patent Status

-World Patent PCT No.KR2007/004427

-U.S.A Patent No.12/673,152

-European Patent No.07 808 218 7

-Korea Patent No.10-0755017, No.10-0878296

-Innovative, Reliable Original Vibro Ripper in The World!

-Powerful digging force by special vibration structure

-Noiseless & Eco-friendly Vibrating Ripper

-No scattering of debris during digging operation

-Higher Production & efficiency

-Noiseless and eco friendly equipment (approx. 52~65dB lower than an equivalent hammer)

-Up to double and three times of productivity compared with an equivalent hydraulic hammer

-Easy installation to excavator with breaker hydraulic lines

-Utilizes 2,700rpm of high frequency vibration

-Patented heavy duty of elastomers(cushion elastomer) insolates the excavator from vibration shock

-Mounting and dismounting with 5~40 ton excavator boom at any time easily

-Innovatively designed tooth & pin have improved the durability

-Powerful breaking performance by high frequency motor

-Innovative technology, more powerful vibration and less noise level than ever

-Increased life time for the equipment by applying the oil rotation power system

-Developed with a patented high frequency vibration technology world first, which makes it in 80% of job site more productive than any rock breaker.

-Application area : it can work in tunnels, road extension section, public grievance, downtown, foundations, muddy, wet zone and under water places

Technical Specification of Vibro Ripper (DBL Series)

- Q: I've heard that money is good. Where do you sell better quality?

- Yunnan is red soil, soil viscosity is relatively strong, strong choice, pile driving machine, no artificial shovel soil, as long as there is a live three months can earn the cost of piling machine

- Q: What about the engine power of a hydraulic pile driver?

- The utility model has the advantages of stable performance and reliable use, and can be used for self loading, self unloading and moving transition. During transportation, the upper section of the main frame can be retracted and folded, thereby saving a great deal of expenses and troubles in lifting and dismounting. The pile machine is not only efficient, economical and practical, it is the best choice for customers, but also can adapt to various bad weather and working conditions of the operating environment.

- Q: The piling machine and the appearance are not considered as large machinery import and export fields

- The foundation pile driver is different from the other machines and should be counted

- Q: Is the prestressed pipe pile driven by a diesel pile driver or a static pile driver?

- Hydraulic press-in is a jacked pile. Hydraulic hammer is a hydraulic pile hammer, and also a kind of impact pile. The single acting hydraulic hammer is only the rising driving mode, which is hydraulic and then released. The double acting hydraulic hammer also uses hydraulic acceleration when falling down. The speed is fast, and the lighter hammer core can be used. The impact force is larger than the ordinary one, and the steel pile is usually used

- Q: What kind of industry can use a pile driver?

- Pile driver: economic development, led to the rapid development of the industry, especially in recent years, urban and rural areas and highways, railways, power stations and other construction to accelerate the development of pile machinery. Such as our factory production of this kind of pile machinery, more subdivision, more widely used.?Piling machine basically can be divided into hydraulic piling machine, foundation piling machine, piling machine, photovoltaic power plant hammer piling machine, hammer piling machine and four kinds of diesel hammer piling machine. Each kind of work principle is not the same.

- Q: Is there a construction site for solar powered PV pile drivers?

- There are shallow foundation storage pile foundation, and the foundation is divided into natural foundation and foundation for artificial foundation treatment. Even if your building needs a pile foundation, there are many ways to do it...

- Q: PV pile driver

- Shandong Tengzhou production of this idiot manufacturers have a few, can come to Shandong to look strong, has many years of construction experience in complex terrain. Can prevent landslides and broken stones.

- Q: How much is the average cost of piling a metre?.Construction Engineering piling machine how much money? (can be more than 30) piling generally hit a meter, what is the cost?. How much can I pay for a metre? What's the procedure for piling operators?

- Domestic about 2000000, the best to count Germany and Italy one, at least 500 - about 6000000! About one meter.

- Q: Can a pile driver hit a rock?

- In a spiral track Matlock advantage:1 、 simple operation, one hole forming,2, fast, 3-5 minutes can become holes 5 meters3, the maximum diameter of the hole 800mm, the maximum hole depth of 10m, suitable for housing construction, highway, high-speed rail slope protection and other pile foundation construction4, special, mobile convenient, 360 degrees of free rotation5, firewood and electricity dual-use, reduce cost expensesA Hui Omron caterpillar rotary drilling rig advantage:1, the fastest 20 minutes, you can dig 5-8 meters of earth drilling2, drilling can break strong weathering rock layer3, the well-known brand of the engine, "Yuchai, Weichai, fuel consumption 40-50 yuan per hour.4 、 selection of multi-functional parts, such as: Clay bit, sand fishing drill, bottom drill bit, easy to change, practical.

- Q: What pile driving machine should be used for the 400*400 square pile?

- When in operation, the pile hanging in place pile frame in Longmen, then put the diesel hammer at the top of the pile, the hook will lift down the cylinder, and the cylinder sleeve off hook to the whereabouts of the piston, the cylinder will be closed in the air compression cylinder rocker pin until the pressure continues to fall outside the cylinder pushing hammer on the base of the fuel pump, fuel pump will be injected into the cylinder oil mist, oil mist meet high temperature gas burning immediately above, blasting, explosive shock down pile., to push the cylinder to cylinder to rise, fall along the guide rod, and the beginning of the second impact cycle.

1. Manufacturer Overview

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vibro Ripper (DBL Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Sets watt

- Supply Capability:

- 1000 Sets per Month watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords