CMAX 1060B-II Series Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX Series Hydraulic Static Pile Driver for Sale

ZYJ series hydraulic static pile driver is the product for building pile foundation construction under the independent research and development of our company and with more than 10 national patented technologies. It is a novel environmentally friendly construction equipment characterized by no pollution, no noise, no vibration, fast pressing of pile as well as high pile quality, and represents the development direction of piling machinery. Since mass production, its domestic market share has been firmly first, and our company has become a professional enterprise with research and development, production and sales of domestic pile machine taking the lead. The product won the second prize of the State Scientific and Technological Progress Award in 2003, becoming the famous-brand product of Hunan. Our company participated in drafting the Hydraulic Pile Driver industrial standard (JB/T11674 2013), which greatly promotes the development and progress of technology of static pile driver and pipe pile industry in China. Our company completed the upgrading of product design in 2013 to comprehensively improve the configuration, performance and quality, and the products are well welcomed and praised by the customers since it was put on the market.

Feature:

1. High-efficiency and energy-saving piling system with quasi constant power

2. Humanized driver cab and concise and clear control console

3. Piling oil cylinder and motor pump set with scientific and reasonable matching

4. Patented technology - fast return of piling oil cylinder

5. Clear and simple hydraulic piping layout

6. Patented technology - multipoint pressure-equalizing gripper mechanism

7. Unique "side piling and angle piling" device

8. Steel H-shaped pile can be pressed into the trapezoidal and triangular piles according to customer requirements.

9. Simple structure and easy transport

10. New hydraulic walking chassis

11. New patent – side piling device

| Parameter | ZYJ1060B-II | |

|---|---|---|

| Dimension | Length mm | 16440 |

| Width mm | 9160 | |

| Height mm | 3010(3220含吊机) | |

| tf Max.piling force | 1060 | |

| m/min Max.piling speed | 7.6 | |

| Travel Capacity | Lengthwise m | 3.6 |

| Widthwise m | 0.7 | |

| Angel ° | 5° | |

| Standard crane model | QY25C | |

| Grounding Pressure | (Kpa)Long ship | 154 |

| (Kpa)Short ship | 215 | |

| Side pile distance mm | 995 | |

| Comer pile distance mm | 2500 | |

| Max round pile mm | 800 | |

| Max square pile mm | 600 | |

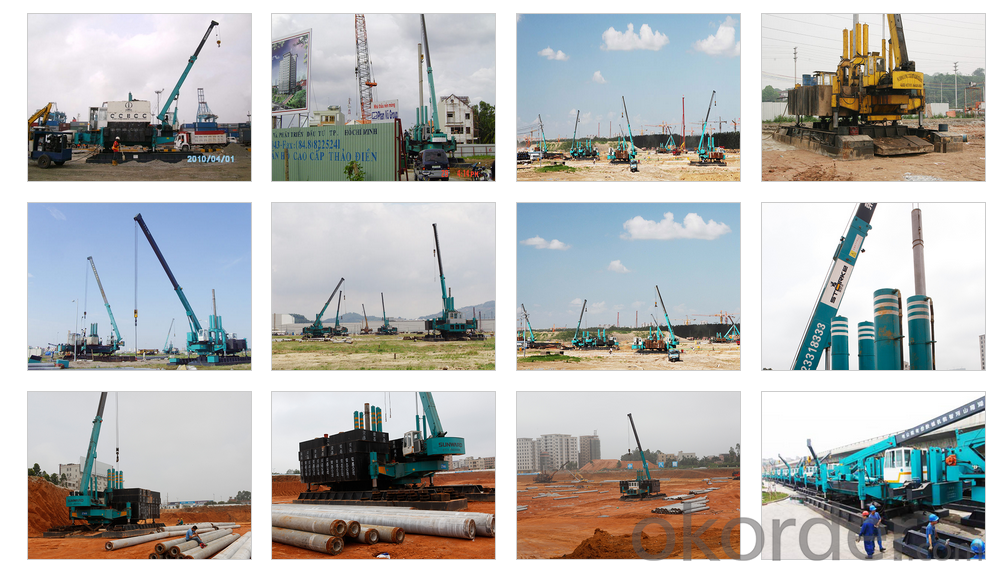

Cases

Cases

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

Driver by pile hammer, and accessory equipment, etc.Pile hammer attached on the front of pile frame, between two parallel vertical guide rod lifting hook to lift.Pile frame for a steel structure tower, hoist are set in the back, to lifting pile and pile hammer.Pile frame consists of two guide bar in front of the guide frame, used to control the driving direction, make the pile penetration formation in accordance with the design orientation accurately.Driver is the basic technical parameters of the shock part weight, kinetic energy and impact frequency.Pile hammer according to the movement of the power source can be divided into the drop hammer, hammer, diesel hammer, hydraulic hammer, etc.Using impact to the pile penetration formation of pile driving machinery.Driver operating personnel must be familiar with the mechanical structure, performance, operating essentials and security considerations, after having obtained the certificate of approval, the examination and can separate operation.After pile driver to stop working, should immediately cut off the power supply, inspection, maintenance and the driver and motor.The driver stopped for a long period of time, warehouse storage, motor should be moistureproof protect, instrument on the control panel, should remove the packing.

- Q: What does "driving pile" mean based on dynamic compaction?

- The dynamic compaction method can improve the strength of the foundation soil, reduce the compressibility, collapsibility and improve the ability of anti liquefaction and elimination of soil, suitable for processing the gravel soil, sand, silt, clay, and miscellaneous fill soil foundation, is often used for treatment of liquefiable sand soil and collapsible loess the foundation.

- Q: How many meters can a small pile driver reach?

- 1.2 meters in diameter, wylong machinery had sold a small machine

- Q: There are also some related costs. Originally wanted to buy a pile driver, the budget of 100-200. I hope my friends will give me some advice.. Thank you

- Depends on what project you do, if there is no noise requirements, diesel hammer piling machine is better, a price at about 500000, back to Ben faster. The hydrostatic press is a bit heavy.

- Q: How many prestressed concrete pipe piles can a pile driver hit in a day?

- The degree of proficiency of your worker has something to do with geology. Normally, it's about 400 meters a day.

- Q: But in a few days, wait for the water to ease up, and plug it directly with earth rockIs there no way directly to seal the breach?

- The width of 340 meters, so excited water, so a wide breach, the water is so deep, the boat stopped, so how long pile up? Where is the man standing? People have no place to stand. How can the pile driver be put into the wooden pile? Under such circumstances, even if there is a pile driver, what's the use? This is the changkai dike breach after there are no reasons for piling piling machine.Answer to your supplementary question:Closure of crevasse is a system engineering, it should include: pile, piling machine, operating platform, platform connection between the anchor pile, etc.. Not only one or two of them can be done.The following is the Liyang Ding Ding Mini piling equipment factory produced dragon dragon brand dam information, hoping to help answer your questions, if you do not see clearly, you can click on the map to see the original picture.First, dragon Ding card dam mapSorry, I'm only level one now. I can't upload pictures. If necessary, go to the website of the new tripod piling equipment factory in LiyangTwo, the Dragon Dingpai dam burst when the working drawing of pluggingThree, dragon card blocking effect after the burst dam closure graphWhen all of the pile are good, can seal the 90% water, finally burst all filled with debris, if there is enough manpower, also can be in front of the pile at the same time, immediately behind the embankment filling. Crevasse sealing is completed, will pull out all the repeated use of pile.

- Q: Why do some people need to dig the foundation and pile it up to dig a hole?

- Digging foundation, piling and digging, piling are twoGenerally after the first pile driving, dig the foundation, you think, I pile is to pile machine back and forth, you dug the pit, how the machine down to pit how to walk, the foundation pit bearing capacity is not enough or the foundation pit is disturbed,

- Q: Safety requirements for diesel hammer pile drivers for diesel hammer pile drivers

- 1, the pile driver walking and slewing, hanging pile, hammer should not be carried out simultaneously. The pile driver shall not turn or walk in full swing after hanging the pile. 2 Side Piling and long distance pulling pile are not allowed in pile driver. When the pile is hoisted in front, the horizontal distance of concrete shall not be greater than 4m, and the steel pile shall not be larger than 7m, and the pile shall be prevented from colliding with the post. 3 when the column is turned into place and the column is locked, the piling frame of the double guiding post can be operated. 4 before the start of the diesel hammer, the pile hammer, the pile cap and the pile should be on the same axis, and shall not be driven by eccentric piling. 5 in soft soil pile driving, should first close the throttle, cold beat, to each attack penetration is less than 100mm, can start the pile hammer. 6 after the start of the diesel hammer, the landing gear should be lifted. The distance between the landing gear and the top of the cylinder of the cylinder hammer shall not be less than 2m during the hammering process. 7 when the diesel hammer is running, the jumping height of the impact part shall be visually observed, and the requirements of the instruction manual shall be strictly enforced. When the required height is reached, the throttle shall be reduced and the stroke of the impact part shall be controlled. 8 during the operation, attention should be paid to the change of the soil layer and the operation of the pile driver, and the necessary measures should be taken in time. 9 diesel hammer appear early ignition, should stop working, according to the instructions for processing. 10 when the piston jumps on the cylinder hammer, the grease should be observed to flow out of the drain hole. The lubricating oil of the lower piston shall be filled according to the instruction manual.

- Q: What safety measures should be taken when assembling a pile driver?

- This thing must have the safety, rules and regulations, but the key is to have this awareness, the following for your reference, I hope to help you.1 、 safety management system of mechanical equipmentLeaders at all levels should strengthen the safety work of mechanical equipment often carry out safety production leadership, ideological education and safety education of workers, the leaders at all levels included in the safety target management schedule, prohibited illegal command, illegal operation, violation of labor discipline and reckless ignorance and other unsafe behavior, leaders should regularly organize relevant personnel go to the scene, the supervision and inspection of mechanical safety work, to correct the problem, promptly eliminate hidden dangers, make the mechanical equipment to achieve safety, high quality, high efficiency and low energy consumption operation, the long-term safe production and take measures to eliminate hidden dangers and prevent accidents of personnel should be commended and rewarded.Urge all kinds of machinery and equipment operators to seriously study safety technical operation procedures, and those who violate safety technical procedures must be stopped, and can be continued before improvement. After the arrival of the new model, there is no safety technical operating procedures, it must be in accordance with the requirements of the instructions, first formulate safety operation procedures and precautions before they can be put into use.

- Q: HD50 cylinder type diesel hammer, HD62 hammer, HD80 hammer, walking pile driver, crawler type pile driver

- HD50 refers to the 5 tons of diesel pile hammer; HD62 refers to the 6.2 tons of diesel pile hammer; HD80 refers to the 8.2 tons of diesel pile hammer; walking pile driver is walking pile frame supporting diesel pile hammer general "walking hammer" or "walking type diesel pile hammer" or "walking type diesel pile hammer";

- Q: Is there an operation certificate for percussive drill driver?

- at the top of the main frame is fixedly connected with the pulley first, the lower part is provided with a steering pulley, the pulley head and a steering pulley connected by wire rope transmission; one end of the wire rope is fixedly connected with the hammer, the other end is connected to a winch Part; the manipulation of PLC electric control box, automatic operation mechanism began to work, you can control the opening and closing part of piling winch clutch, the automatic impact drill piling machine has the advantages of simple structure, low cost, convenient operation, reliable performance.

Send your message to us

CMAX 1060B-II Series Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords