ZYC series ZYC1200B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

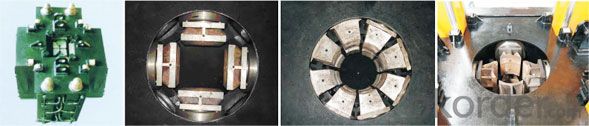

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 1200 | suitable pile & specification(mm) | ¢400-800 | |

| Max. Piling speed(m/min) | 7.5 | Max. Crane lifting weight(t) | 25 | |

| Piling stroke(m) | 1.8 | Hanging pile length(m) | 15 | |

| Max. Longitudinal pace(m) | 3.6 | Minimum side piling space(mm) | 1650 | |

| Max. Transverse pace(m) | 0.52 | Minimum corner piling space(mm) | 3000 | |

| Max. Rise stroke(m) | 1.1 | Intensity of pressure(tf/m²) | 18.8/23.2 | |

| Max.rotation angle per time(°) | 8 | Weight composition | (t) Machine weight | 263±4 |

| Rated hydraulic system pressure(mpa) | 25(20) | Added water weight(t) | 55 | |

| Hydraulic Pump (Unit × Ml/Turn) | 3×125+1×125 | Counter weight(t) | 882 | |

| Motor power (Unit × kw) | 3×37+1×37 | Total weight(t) ≥ | 1200 | |

FAQ

To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q: What kind of pile driver, rotary drilling machine can drill under medium weathering rock layer?

- The Xugong power head, wylong machinery mechanical lock rod rotary drilling rig Yuchai engine and can be weathered rock and sediment layer in the layer below, backfill soil drilling construction

- Q: What is the power of the pile driver?

- Hello, there are many kinds of power in the pile driver. How big do you need?.

- Q: Want to mortgage a hydraulic pile driver?. Excuse me, what brand, what tonnage is more competitive?.Could you introduce the profit, expense, cash flow of piling machine, the more detailed, the better.

- Qingyuan Xin Feng Machinery Factory production of 2 Taiwan good ~ we are the brand ~ I just listen to my father said that the specific amount should be 200 thousand ~ a ~ details of your advice of high manager soldiers accounted for ~ should Baidu can be found in the.

- Q: what kind of VLV cable is needed, how to determine, after the cable from the low-voltage distribution box out, 460m arrived distribution of electricity 100It's best to explain how to calculate, how to determine the current, and the specifications of the cable, thank you very much!630 of the box changed to the distribution box for the cable, 240 of the cable is single core, or 3*240 cable. What kind of cable can be specific about it? Underground directly buried, directly to a cable model, aluminum core cable

- Two way 240 are used together,Pe=75*5=375Kx=1Pjs=pe*kx=375Cos=0.8Ijs=pjs/ue/3/cos=375/220/3/0.8=710Adopt cable specification, 2 way 4*240+1*120 parallel useIn the case of direct buried laying, the selection of outer sheath of cable shall comply with the following provisions:1 when the cable is under greater pressure or has mechanical damage, it should have reinforced layer or steel tape armour.2 in the quicksand, backfill, land and other possible displacement of soil, the cable should be steel wire armored.3 termite serious harm extrusion cable area, should choose higher hardness of the outer protective layer can also be thin in common outer sheath is extruded on the higher hardness of the protective layer, which can be used as the material of nylon or special polyolefin copolymer, also can be made of metal or steel armor.4 the outer layer of polyethylene should be used in areas with high underground water table.5 in addition to the above circumstances, the outer sheath without armour may be used.

- Q: What are the prospects for a small pile driver and a foundation pile driver? Will it make money?

- like Hunan Huilong piling machine is generally divided into: Machine lock rod rotary drilling rig, caterpillar rotary drilling rig, crawler wheel screw drilling machine, rotary drilling rig.

- Q: Safety requirements for diesel hammer pile drivers for diesel hammer pile drivers

- 19, the operation should always check whether the fasteners are loose, the moving parts are flexible. Diesel pile hammer after the operation note 20 after the operation, diesel hammer should be parked in a solid flat ground, diesel hammer should be placed on the ground plate or into underground pile, shutting down the fuel switch, barrel type hammer should be put in the net cooling water, mounted on the cylinder head, exhaust cover, safety screw etc., and mounted on the safety card. The pile holder shall be placed in a stop position, locking the safe and braking position. 21 rail type pile holder should clamp the rail clamp when it is not working. When the 22 pile stand is broken, the brake performance of the hoister shall be checked first, and then operated according to the procedures specified in the instruction manual. 23, long-term disabled, should be unloaded diesel hammer, loaded with safety board, the diesel hammer fuel, lubricating oil and cooling water all out, cleaning the combustion chamber, coated with anti rust oil on the ball bowl, and take rainproof measures.

- Q: Want to buy a small pile driver, I do not know whether it is good track or wheeled good?

- The track is better, the practicability is very wide, not stuck in the mud, and the good wylong machinery!

- Q: How many meters per day can a foundation shovel in Luoyang be 80 centimeters in diameter? Is it easy to damage?

- Look at the geological situation, the day is also a lot of big, how to say this thing, you do more work, certainly the loss of large, simple construction of this machine

- Q: The principle of pile driver

- The principle of a pile driver is the use of impact force to pile into the formation of the pile machinery.Construction of piling machine is composed of pile hammer, pile frame and ancillary equipment etc.. The pile hammer is attached to two parallel vertical guide rods (commonly called Longmen) at the front of the pile support and hoisted with lifting hooks. The pile foundation is a steel structure tower with a windlass at the back of which is used to lift the pile and hammer. A guide frame consisting of two guide rods is used in front of the pile to control the direction of the pile driving so that the pile can be accurately penetrated into the formation in accordance with the design orientation. The tower and the guide frame can be used to batter pile deflection. The guide frame can also be extended downward along the tower and used to fetch water along the embankment or pier. The pile can move and move. The basic technical parameters of a pile driver are impact weight, impact kinetic energy and impact frequency. According to the motion of the pile hammer power source can be divided into hammer, hammer, diesel hammer, hydraulic hammer etc..Piling machine type: piling machine and rotary drilling pile machine, with spiral to the underground digging, then pouring pile.

- Q: Is there an operation certificate for percussive drill driver?

- The following is the introduction of can refer to the utility model relates to an automatic drill piling machine, the piling machine has a movable chassis, the chassis of the upper lateral order device PLC electric control box, automatic operation mechanism, hoisting part and a steering pulley and a main frame; PLC electric control box is provided with a computer program controller.

Send your message to us

ZYC series ZYC1200B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords