ZYC series ZYC400B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

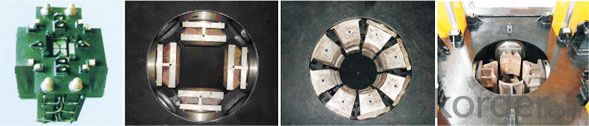

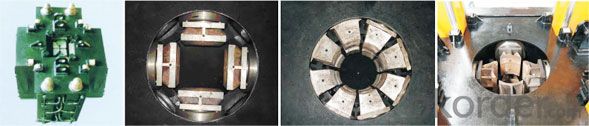

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 400 | suitable pile & specification(mm) | □200-400 ¢300-500 | |

| Max. Piling speed(m/min) | 7.0 | Max. Crane lifting weight(t) | 12 | |

| Piling stroke(m) | 1.8 | Hanging pile length(m) | 14 | |

| Max. Longitudinal pace(m) | 3.6 | Minimum side piling space(mm) | / | |

| Max. Transverse pace(m) | 0.6 | Minimum corner piling space(mm) | / | |

| Max. Rise stroke(m) | 1.0 | Intensity of pressure(tf/m²) | 12.3/13.1 | |

| Max.rotation angle per time(°) | 11° | Weight composition | (t) Machine weight | 133±2 |

| Rated hydraulic system pressure(mpa) | 23(20) | Added water weight(t) | 30 | |

| Hydraulic Pump (Unit × Ml/Turn) | 3×80 + 1×80 | Counter weight(t) | 237 | |

| Motor power (Unit × kw) | 3×37 + 1×30 | Total weight(t) ≥ | 400 | |

FAQ

To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q: Piling machines need to how much money??

- See how many meters you need, there are 13.5 meters to 20 meters, there are 5 meters to 8 meters, the performance is not the same

- Q: Like bored pile machines and precast pile machines, they have no wheels, and they are very bulky. How do they move?Some people say that the demolition and then installed, a construction site three hundred or four hundred piles, it is difficult to dismantle three hundred or four hundred times?

- By hydraulic, the two sides of the foot support on the ground, palm the main body, and then the main sliding distance, and then the main body falls, complete a slide, you can also wisdom vertical 90 degrees in the direction of sliding.

- Q: The difference between diesel pile driver and impact drilling machine

- A diesel pile driver: like a hammer hitting a nail, it is hit by a hammer.

- Q: Why levy piling

- Because the foundation bearing capacity of the building is low, it can not meet the load requirements of the upper building. Piling is to pass the weight of the building to the soil with high bearing capacity of the foundation. Not all buildings are piling, and if the bearing capacity of the foundation meets the requirements, the pile can not be piled completely. Like Beijing, few piles are used because of the good bearing capacity of the foundations.

- Q: I have two pile drivers, followed by engineering piling, what qualifications do you need?

- Hang on it, for qualification trouble. You can contact me if you need to buy piling equipment.

- Q: now to pull out, how can pull out? FiveThe machine can not be used, how to take out in a simple way! Now, how many tons of jacks do I need if I use a jack?

- Is it possible to use a vibratory hammer, or a hydraulic high frequency vibrator?.

- Q: How much is the hydraulic pile driver?

- Between 16-40, 000. Different manufacturers. Different tonnage difference big ah, soft land dozen20 tons will be enoughI hope my answer is useful to you, if satisfied, please take ~!

- Q: The pile driving team has many years of piling experience, to undertake the construction of large and small piles, includingKongguanzhu

- To consider how the site can take back the unearthed excavation method is ABC pile test done to dig a long tight schedule but also increase the test equipment such as AC two AC after completion of the test sequence can also do a ramp to the middle of the excavation

- Q: Can the piling machine be built at night?

- In principle, it is not allowed to work at night, unless it does not affect anyone's life, study and work, and does not constitute noise pollution.

- Q: Does the pile driver belong to special equipment?

- Special equipment is the safety of life, the risk of large boilers, pressure vessels (including gas cylinders, the same below), pressure piping, elevator, crane, passenger ropeway, large recreation facilities and special motor vehicle factory. Piling machine does not belong to special equipment

Send your message to us

ZYC series ZYC400B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords