ZYC series ZYC120B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

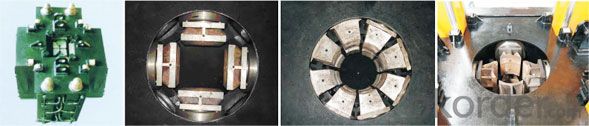

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 120 | Specifications for suitable piles (mm) | 200-300 ¢300 | |

| Max. Piling speed(m/min) | 3.0 | Max.lifting weight of Crane (t) | 5 | |

| Piling stroke(m) | 1.5 | Hanging pile's length (m) | 10 | |

| Max. Longitudinal pace(m) | 1.6 | Min.side piling space(mm) | 450 | |

| Max. Transverse pace(m) | 0.4 | Min.corner piling space (mm) | 1000 | |

| Max. Rise stroke(m) | 0.8 | Hydraulic Pump (Unit × Ml/Turn) | 1×63 + 1×25 | |

| Angle range(°) | 15° | Rated hydraulic system pressure(mpa) | 23(16) | |

| Intensity of pressure(tf/m²) | 8.8/8.3 | Weight composition (t) | Machine weight | 52±1.5 |

| Motor power (Unit × kw) | 1×22 + 1×11 | Angle range(°) Counter weight | 71.4 | |

| Total weight≥ | 120 | |||

FAQ

To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q: What does "driving pile" mean based on dynamic compaction?

- The dynamic compaction method can improve the strength of the foundation soil, reduce the compressibility, collapsibility and improve the ability of anti liquefaction and elimination of soil, suitable for processing the gravel soil, sand, silt, clay, and miscellaneous fill soil foundation, is often used for treatment of liquefiable sand soil and collapsible loess the foundation.

- Q: Is there a pile driver in it?

- However, the piling machine is not stable, but also a team together. And we're going out of town, this month, ten days.

- Q: What's the difference between a track type diesel pile driver and a crawler diesel pile driver?

- 3) apply distinctionIn terms of technology, economy and efficiency, their application has its own emphasisTrack type diesel pile driver: generally used for large piles, deep pile, Caterpillar diesel pile driver: generally used for small piles, shallow piles

- Q: But in a few days, wait for the water to ease up, and plug it directly with earth rockIs there no way directly to seal the breach?

- 18:30 on June 21, 2010, Nadekawa sang Kay dike burst. On the morning of June 22nd, the measured changkai dike burst width of 340 meters. 25 days 12 when monitoring data: diwai water level 36.08 meters, 35.90 meters, the water level was an average depth of 4.06 meters, the water area of 1170 square meters, the average flow of 1280 cubic meters per second, the flow rate of 1.09 meters per second. (excerpt from: Fuzhou Hydrological Bureau Author: Liu Jianming)From 18:30 on June 21st to 25, 12, that is, in 90 hours after the average flow rate of 1.09 meters per second, it is estimated that within 24 hours of the dike burst, the average flow rate should be 5~8 meters per second or higher. And the average depth of 4.06 meters, according to the wooden pile into the water 3 meters, 1 meters above the surface, the length of the stakes should be no less than 8 meters.

- Q: Requirements of waveform guardrail column piling skills training program and training program.

- B, anti blocking blocks, wave beam, end installation(a) after installing the upright column, the bracket (block block) can be installed. The bracket (stop block) is fixed between the wave beam and the upright post through the connecting bolt. The bracket (block) shall be adjusted to make it in place before tightening the connecting bolts.(b) the wave beam is spliced with each other by a splicing bolt and is fixed by a connecting bolt bracket (an anti blocking block), and the direction of the overlap of the roadbed guardrail and the corrugated beam is the key of the installation, and the installation is carried out in strict accordance with the drawing. The direction of overlap shall be consistent with the driving direction. The wave beam should be adjusted continuously during the installation. Therefore, the connecting bolts and the splicing bolts should not be tightened too early so that the long holes in the corrugated beam can be adjusted in time during the installation process so as to form a smooth alignment and avoid local irregularities. When the alignment of the guardrail is considered satisfactory, the bolt can be screwed at last. The connecting bolt between the bracket (stop block) and the wave beam should not be screwed too tight, so that the temperature stress can be adjusted by using a long round hole.(c) the end beam is spliced with standard section guard bars through splicing bolts. The construction method of the end beam is basically the same as that of the wave beam.

- Q: such as bulldozers, pile drivers, cranes and cement mixers?

- (three) market specialization;Market specialization refers to the production of enterprises to meet the needs of a certain type of customer groups, specializing in the production of such consumersVarious types of products, such as an engineering machinery company, supply bulldozers and pile drivers specially to construction users,Mechanical equipment needed for construction, such as cranes, cement mixers, etc.There are many types of products which can effectively disperse the business risks, but because they are concentrated in a certain kind of customers, when such customersFor some reason, demand falls, and firms are at risk of lower earnings

- Q: Several common pile foundations and pile driving techniques

- Sinking into the pile foundation - Hammer Sinking Pile into the pile, the main construction methods are: Hammer Sinking Pile, vibration pile, static pressure pile and immersed pipe pile. The hammer sinking pile is generally applicable to medium density sand soil and cohesive soil. Because the pile driving hammer will sink the pile and hit the pile against the impact energy of the pile hammer, so the general pile diameter can not be too large (not more than 0.6m), and the buried depth is not greater than 50m. Sinking pile foundation pile, cast-in-place pile is the reinforced concrete or steel pipe pile tip with valve pile tip at the bottom of the sleeve, sinking to the required depth by hammering or vibration, the tube placed inside the reinforcement cage, concrete pouring, pull out pipe forming.

- Q: What is a loading type road pile driver?

- The emergence of the loader pile driver is a breakthrough in the piling machine industry. It not only improves the efficiency of drilling, but also has the ability to work at night as well as the ability to prevent rain and water. It has longer life, better quality and, of course, more expensive prices. But in general, it's good value for money.Traditional road pile driverThe traditional highway pile driver doesn't have the working conditions at night and rainy day, but the punching efficiency is high, but it is not as good as that of the loading type road pile driver. It looks shabby.

- Q: What machinery is suitable for a PV pile driver?

- Are you talking about a small hammer pile driver for excavators? If you are playing a photovoltaic pile (hollow pipe pile) below 9 meters, you can use the north Yi Machinery BY-YH250 model of small hammer piling machine, installed on excavators.

- Q: How many small pile drivers are there in Hunan? It's best to have the exact location

- Hunan small piling machine manufacturers or a lot, like Hunan wylong machinery should be more excellent in mechanical industry.

Send your message to us

ZYC series ZYC120B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords