ZYC series ZYC700B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

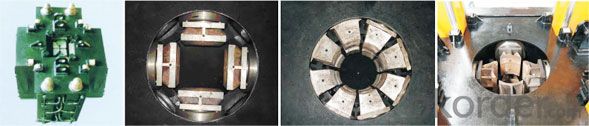

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 700 | suitable pile & specification(mm) | ¢300-800 | |

| Max. Piling speed(m/min) | 5.9 | Max. Crane lifting weight(t) | 16 | |

| Piling stroke(m) | 2.0 | Hanging pile length(m) | 15 | |

| Max. Longitudinal pace(m) | 3.6 | Minimum side piling space(mm) | 1380 | |

| Max. Transverse pace(m) | 0.6 | Minimum corner piling space(mm) | 2800 | |

| Max. Rise stroke(m) | 1.1 | Intensity of pressure(tf/m²) | 14.2/19.4 | |

| Max.rotation angle per time(°) | 11 | Weight composition | (t) Machine weight | 186±3 |

| Rated hydraulic system pressure(mpa) | 25(20) | Added water weight(t) | 48 | |

| Hydraulic Pump (Unit × Ml/Turn) | 3×80 + 1×80 | Counter weight(t) | 466 | |

| Motor power (Unit × kw) | 3×37 + 1×30 | Total weight(t) ≥ | 700 | |

FAQ

1.To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

2. On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

3. After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

4. Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

- Q: AMD pile driver FX-8350 with what motherboard good?

- From the practical point of view, FX-8350 with AMD970 motherboard is enough, as for the brand, it is recommended to choose gigabyte, MSI, ASUS and other brands.Introduce one of the ASUS M5A97 LE R2.0 motherboard parameters:The main chip group: AMD 970;

- Q: What are the preparations for the piling site?

- 1, the pile position determination: according to the project provided by the construction unit and the pile axis location map of pile location, pile location must be accurate, and in the pile position by a soldering iron drilling, hole depth is 15~20cm, filled with lime, prevent in the process of driving the wrong pile.2. Pile up(1) pile stacking shall be determined by pile driving route and pile driving sequence(2) the site shall be level and level with three passes and one leveling. Remove obstacles in the ground, underground and air in the range of the moving of the pile driver. The wooden posts and the pile rings shall be of the same position, except for the contact between the pile and the pile, and nothing else shall be in contact with the pile so as to prevent cracks in the pile.(3) the strength of reinforced concrete precast piles must be up to 100% before they can be transported and piled3, the selection of pile machineAccording to the design of single pile bearing capacity and pile length, this project intends to use hammer weight 2.5t track type diesel pile driver.

- Q: Excavators, pile drivers, how to operate? The master knows,

- Simple, first stop the car, push the right handle forward (big arm down), push the left hand lever (small arm out), handle the right (release bucket), do the above three actions at the same time until the bucket touches the ground. Then, the left handle back down and right arm handle down the left arm when receiving bucket, bucket is full. Then the big arm, left or right rotation and small rotating arm bucket on the line! Got it?! You can also question me!

- Q: How many piles can a small pile driver hit in a day?

- See you hit the big pile, 600 5 meters deep as long as 5 minutes, 1.2 meters high 5 meters deep as long as 20 minutes, without concrete words, you can calculate according to the time

- Q: Pile driver model, which brand is better?

- As for the piling machine brand small piling machine is recommended a Matlock in Hunan, the drilling machine is widely used in city high-rise buildings, railways, highways, bridges, airports, ports and other pile foundation engineering irrigation pile construction, has wide application range, high construction efficiency, stable performance, and thoughtful service, environmental protection and energy saving the advantages of.

- Q: What type of machine is needed for highway foundation piling machine? Price?

- This series of drilling machines is a new type of pile foundation construction machinery, which adopts hydraulic walking, electric control and long auger drilling. Hydraulic drive chassis can achieve 360 degrees of full swing, in place, move, tune, equal action, fast and accurate. The utility model can be used for carrying out the drilling operation, and the steel cage can be lifted by itself and the grouting operation can be carried out by adopting two electric control winches. The output shaft of the power head is hollow, and besides the general long spiral dry method, the deep mixing method can also be applied.

- Q: AMD FX 8350 eight core CPU AM3+ piling machine and tin box what is the difference between the master pointing

- All one to。 Most of the cartons were in 2013. But in 2012, they were all iron boxes. And the radiator of the paper box doesn't have the radiator of the iron box. Although the AMD platform U original box radiator is no use. But I always feel sick. Bought on Jingdong.

- Q: PV pile driver

- The PV pile driver has both wheel and track components. The tracks are divided into generators and full hydraulic ones. Shandong Tengzhou production of this idiot manufacturers have a few, can come to Shandong to look strong, has many years of construction experience in complex terrain. Can prevent landslides and broken stones.

- Q: How much is the average cost of piling a metre?.Construction Engineering piling machine how much money? (can be more than 30) piling generally hit a meter, what is the cost?. How much can I pay for a metre? What's the procedure for piling operators?

- Domestic about 2000000, the best to count Germany and Italy one, at least 500 - about 6000000! About one meter.

- Q: What's the use of a pile driver?

- The pile driver is used for the soft foundation treatment of buildings, high-speed railways and so on. First, drilling and pouring concrete,

Send your message to us

ZYC series ZYC700B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords