Pile Driver (DPD Tilting Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Pile Driver (DPD Tilting Clamp Type Series)

-360 degrees free rotation & 90 degrees tilting rotation of jaw clamp

-Simple replacement tooth of pile clamp

SHEET PILE DRIVER (TILTING TYPE)

DPD Tilting Series

(PATENT NO.10-0851430)

- 30% better efficiency of construction working site

- 90 degrees Tilting devices

- Easy & Accurate control tilting operation system

- Tested safety through double device

- This leads to greater customer satisfaction!

- The tilting sheet pile driver can be operated alone ; No necessary assistant worker

- As it tilts up to 90 degree, the operation with sheet pile, H beam, tube, pipe, and steel can easily be controlled without the help of another worker. The cost of one worker can be saved

- Maximizes operational performance with its much more enhanced functions

- Best in 35 ton class for impulse and clamping power

- Dramatically reduces costs of transport and assistant worker

- Highly improved sheet piling operation method

- Extended service life using a special bearing designed for high frequency vibration

- Heavy duty Special elastomers (Patent) isolate vibration protecting the excavator from damage

- Making the best use of the excavator, operation in a narrow space is possible

- Easy installation using breaker hydraulic lines of the excavator and electric one control cable device

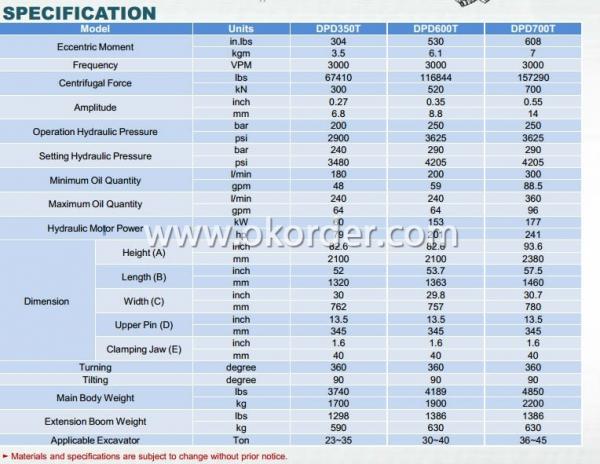

Specification of Pile Driver (DPD Tilting Clamp Type Series)

- Q: Piling machines need to how much money??

- Hello, this is not necessarily, because the configuration is not the same, so the charge is not the same!

- Q: I have learned how to drive a pile driver. I want to know what the salary is. How can I find a job in the future?

- Into the company, there will be no worry about work, such as the construction of the railway these big projects, you need such talent, but it will be very hard, and wages than other drivers of high wages

- Q: Piling of percussive drilling

- 7, the drilling process control should be rigorous, but also do not have to worry about failure, a reasonable choice of treatment methods, generally can be solved, the common, foot blade perforation, hole collapse, partial hole, cross hole, drilling, drilling, drilling buried crane, well preventive measures are generally not in advance, very important duty responsibility. 8, the remaining holes, steel cage decentralization, concrete pouring, sealing and other are more conventional, do not write more. But the bottom of the hole, sediment, sediment, etc. must be recycled clean, otherwise it will be buried in the later works of greater risk. When the concrete is poured, the bottom concrete under the impact of residue inclusion in steel or bond caused by defects in the pile in concrete, on the upper structure of the load transfer to the bottom of the pile, the structure will definitely should produce uneven settlement for residue.

- Q: say no money, the machine is more expensive, but still busy every day do not win, do not know is true or false?

- Certainly money ah, now people are selfish, just want to make money, Matlock machine good, I also encountered such a thing.

- Q: What are the preparations for the piling site?

- 1, the pile position determination: according to the project provided by the construction unit and the pile axis location map of pile location, pile location must be accurate, and in the pile position by a soldering iron drilling, hole depth is 15~20cm, filled with lime, prevent in the process of driving the wrong pile.2. Pile up(1) pile stacking shall be determined by pile driving route and pile driving sequence(2) the site shall be level and level with three passes and one leveling. Remove obstacles in the ground, underground and air in the range of the moving of the pile driver. The wooden posts and the pile rings shall be of the same position, except for the contact between the pile and the pile, and nothing else shall be in contact with the pile so as to prevent cracks in the pile.(3) the strength of reinforced concrete precast piles must be up to 100% before they can be transported and piled3, the selection of pile machineAccording to the design of single pile bearing capacity and pile length, this project intends to use hammer weight 2.5t track type diesel pile driver.

- Q: What kind of industry can use a pile driver?

- The steel pipe pile can be driven into or pulled out according to different configurations or drilled on the subgrade and stabilizing layer before piling.Drop hammer pile driver is a pile tube drop device has simple design, convenient installation and transportation, strike force, stable performance characteristics is a heavy piece of steel, by using the hook lifting winch, after decoupling along the guide frame free fall and piling. All use of electric power, without the purchase of expensive diesel power.Hammer piling machine is composed by hammer hammer and the hammer seat, with steam or compressed air as a driving force, a single action and double action two hammer hammer. With steam or compressed air as a driving force, a single action and double action two hammer hammer. Single acting piston or cylinder as the hammer to hammer, steam driven hammer up, then let the hammer seat along the guide rod fall and piling.

- Q: Why are pile driving boring often deflected?

- What machine? You can not speak this person, piling, Ken positioning, partial hit

- Q: HD50 cylinder type diesel hammer, HD62 hammer, HD80 hammer, walking pile driver, crawler type pile driver

- HD50 refers to the 5 tons of diesel pile hammer; HD62 refers to the 6.2 tons of diesel pile hammer; HD80 refers to the 8.2 tons of diesel pile hammer; walking pile driver is walking pile frame supporting diesel pile hammer general "walking hammer" or "walking type diesel pile hammer" or "walking type diesel pile hammer";Crawler type piling machine is a crawler pile frame supporting tube type diesel hammer general "crawler piling machine" or "Caterpillar diesel hammer" or "Caterpillar diesel hammer"; "HD" should be the product number Guangdong Liyuan cylinder diesel pile hammer

- Q: My family from the building, a three storey, only two and half layer design now, frame structure and prefabricated panels, a total of three half empty, with the inner diameter of the air is piling machine, 30CM in the field, with an average depth of 6 meters, I asked how wide a safe? The master said, "one meter, one. I feel a little too dense."! Ask everybody specially!How many meters can I use if I choose an empty 80CM pile driver? My maximum span is 4 meters, and some are 3 meters and 2 meters. Because the master is how many piles count money, so there is little doubt!

- The spacing of the piles is usually 3-3.5 times the diameter.

- Q: How can I find a pile driver?

- 1, and housing units in charge of the link. Party A has the final say that the foundation works are usually separate from the superstructure.2. Keep in touch with the construction contractor, who will be required to subcontract after work.3, keep in touch with the design unit so that they may design more projects with piles.4, keep in touch with geological prospecting units and collect information.All this has been done and your business can't be done.

1. Manufacturer Overview

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pile Driver (DPD Tilting Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords