Z39 BMP Rolled Steel Coil Construction Roofing Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z39 BMP Rolled Steel Coil Construction Roofing Construction

Description of Z39 BMP Rolled Steel Coil Construction Roofing Construction

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling. Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

Main Feature of Z39 BMP Rolled Steel Coil Construction Roofing Construction

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Applications of Z39 BMP Rolled Steel Coil Construction Roofing Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.  Specifications of Z39 BMP Rolled Steel Coil Construction Roofing Construction

Specifications of Z39 BMP Rolled Steel Coil Construction Roofing Construction

| Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

| N/mm2 | Nominal Thickness mm (t) | |||||||

| JIS | Yogic | 0.25-0.4 | 0.4-0.6 | 0.6-1.0 | 1.0-1.6 | |||

| G3312 | specification | |||||||

| CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

| CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

| ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

| A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

| A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

| A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

| A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

| A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

| A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

| A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

| A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ of Z39 BMP Rolled Steel Coil Construction Roofing Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc .

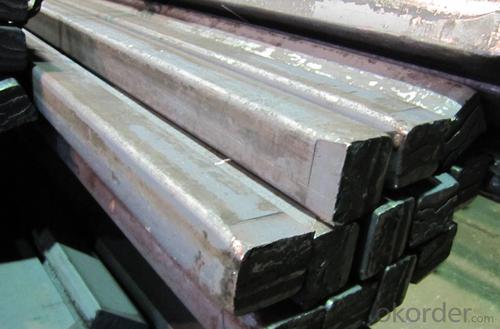

- Q: What are the major steel billet producing countries?

- The major steel billet producing countries are China, India, Russia, Japan, and the United States. China is by far the largest producer of steel billets, accounting for over half of the global production. This is due to the country's massive steel industry, which has experienced significant growth in recent decades. India is the second-largest producer, with a rapidly expanding steel sector as well. Russia is known for its strong steel industry and is the third-largest producer. Japan, although its steel production has declined in recent years, still remains a significant player in the steel billet market. Lastly, the United States is a major producer of steel billets, with a focus on high-quality specialty steel products. These countries play a crucial role in meeting the global demand for steel billets, which are essential raw materials for various industries, including construction, automotive, and infrastructure.

- Q: How are steel billets inspected for internal defects?

- Various non-destructive testing (NDT) techniques are utilized to inspect steel billets for internal defects. Ultrasonic testing (UT) is a common method wherein high-frequency sound waves are employed to detect flaws within the billet. By sending ultrasonic waves into the billet and analyzing the reflected waves, any internal flaws can be identified. UT has the capability to detect defects such as cracks, voids, inclusions, and other irregularities. Another technique used is magnetic particle inspection (MPI), which is particularly effective for identifying surface and near-surface defects in ferromagnetic materials like steel. By applying a magnetic field to the billet and spreading iron particles over its surface, any defects will cause the particles to form visible indications, thereby providing a clear indication of internal flaws. Liquid penetrant testing (PT) is another widely employed method for inspecting steel billets. This process involves applying a liquid dye to the billet's surface and allowing it to penetrate any surface-breaking defects. After a designated time, excess dye is removed and a developer is applied. The developer draws out the penetrant from any defects, making them visible under suitable lighting conditions. Furthermore, radiographic testing (RT) can be utilized to detect internal defects in steel billets. This method utilizes X-rays or gamma rays to capture images of the billet's internal structure. As the radiation passes through the billet, a film or digital detector records the transmitted radiation. Any internal defects will appear as shadows on the image, facilitating their identification. In summary, a combination of these NDT techniques is often employed to ensure a comprehensive inspection of steel billets for internal defects. This aids in maintaining the quality and integrity of the billets, ensuring they meet the necessary specifications and standards.

- Q: How are steel billets packaged for shipment?

- Steel billets are typically packaged for shipment by placing them on wooden pallets or in steel cages. They are then secured using steel strapping or shrink wrap to prevent movement or damage during transportation. Labels are also attached to the packaging to identify the type, quantity, and destination of the billets.

- Q: How do steel billets contribute to the overall recyclability of a product?

- Steel billets contribute to the overall recyclability of a product by being a primary raw material in steel production. When a product made of steel reaches the end of its life cycle, it can be recycled and transformed into new steel products using steel billets. This reduces the need for extracting and refining new raw materials, conserves energy, and minimizes waste, making the overall recycling process more efficient and sustainable.

- Q: How are steel billets used in the production of automotive braking systems?

- Steel billets are used in the production of automotive braking systems as they serve as the raw material for manufacturing brake components such as discs, rotors, calipers, and brake pads. These billets are heated, shaped, and machined to create the necessary brake parts, which are then assembled and integrated into the braking system of vehicles.

- Q: How are steel billets used in the production of mining machinery?

- Due to their unique properties and versatility, steel billets play a crucial role in the production of mining machinery. These semi-finished metal forms are made from raw iron ore and undergo a series of heating, rolling, and cooling processes to achieve their final shape and properties. In the manufacturing of mining machinery, steel billets are the primary raw material for various important components. Heavy-duty structural parts, such as frames, chassis, and support structures, require high strength and durability to withstand the extreme conditions and heavy loads in mining operations. Steel billets also serve as the foundation for critical functional components like gears, shafts, and axles. These components are vital for the proper functioning and control of mining machinery, as they transmit power and facilitate movement. Steel billets offer excellent machinability, allowing them to be easily shaped into the complex geometries required for these components. Moreover, steel billets are used to produce wear-resistant parts and components that can withstand constant abrasion, impact, and wear. Cutting edges, buckets, and crusher liners are examples of such components. Steel billets are often alloyed with elements like manganese or chromium to enhance their hardness, toughness, and resistance to wear. In the production of mining machinery, steel billets are also utilized for hydraulic components and systems. Hydraulic cylinders, valves, and pumps are essential for the operation and control of mining equipment. Steel billets provide the necessary strength and integrity to withstand high-pressure hydraulic systems, ensuring reliable and efficient performance. In summary, steel billets are indispensable in the production of mining machinery. They are used to manufacture various structural, functional, and wear-resistant components that are vital for the reliable and efficient operation of mining equipment. The unique properties of steel billets, including their strength, durability, and machinability, make them an ideal choice for withstanding the demanding conditions encountered in mining operations.

- Q: What are the main surface finishes available for steel billets?

- The main surface finishes available for steel billets include hot rolled, cold rolled, and coated finishes.

- Q: How are steel billets used in the production of agricultural harvesting equipment?

- Due to their strength, durability, and versatility, steel billets are essential in manufacturing agricultural harvesting equipment. These billets are primarily used to construct the frame of various types of machinery, including combine harvesters, threshers, and balers. The frame of agricultural machinery is crucial, as it provides stability and support for all other components. Steel billets are well-suited for this purpose due to their high tensile strength, enabling them to withstand the heavy loads and stresses encountered during harvesting operations. Moreover, steel billets are utilized in manufacturing critical components such as cutting blades, augers, and conveyors. These components are vital for efficient crop harvesting and processing. Steel's excellent wear resistance and toughness make it an ideal material for these parts, as they need to endure the abrasion and impact caused by contact with crops and debris. In addition, steel billets are commonly used in manufacturing hoppers, chutes, and other storage and transportation systems within agricultural machinery. These components are responsible for collecting, sorting, and transferring harvested crops, necessitating robust and reliable materials. Steel billets provide the required strength and rigidity for efficient handling and movement of agricultural products. In conclusion, steel billets are indispensable in the production of agricultural harvesting equipment. Their strength, durability, and versatility enable the creation of sturdy frames, critical components, and efficient storage systems. By using steel billets, manufacturers can ensure the production of reliable and efficient machinery capable of withstanding the demanding conditions of harvesting operations.

- Q: What is the role of steel billets in the construction of bridges?

- The construction of bridges relies heavily on steel billets, which are essential for the production of various structural components. These rectangular bars of steel serve as raw material and are transformed into beams, girders, and reinforcement bars. Beams and girders are fabricated from steel billets and are crucial for providing support and load-bearing capacity to bridges. By heating and rolling the billets into the desired shape, these structural elements are created and then welded or bolted together to form the bridge's framework. In addition, steel billets are used to produce reinforcement bars, also known as rebar, which are vital for giving tensile strength to concrete structures like bridge foundations, piers, and abutments. By reinforcing the concrete with steel billets in the form of rebar, bridges can withstand the forces exerted by heavy traffic, wind, and other external factors. There are several advantages to using steel billets in bridge construction. Firstly, steel is known for its outstanding strength and high strength-to-weight ratio, making it an ideal material for bridges. Steel billets can bear heavy loads and provide the necessary structural integrity, ensuring the longevity and durability of the bridge. Furthermore, steel exhibits excellent resistance to corrosion, which is crucial for bridges exposed to harsh weather conditions and environmental factors. Corrosion can weaken a bridge's structure and compromise its safety and longevity. However, by using steel billets that can be coated or galvanized to enhance corrosion resistance, bridges can maintain their structural integrity over a prolonged period. To summarize, steel billets play a vital role in bridge construction by fabricating beams, girders, and rebar. They provide the necessary strength, support, and durability to withstand heavy loads and external forces. Steel billets contribute significantly to the overall safety, longevity, and functionality of bridges, making them an indispensable component in bridge construction.

- Q: How are steel billets inspected for dimensional accuracy?

- Steel billets are inspected for dimensional accuracy through a series of rigorous processes to ensure that they meet the required specifications. These inspections are crucial as any deviations in the dimensions can have a significant impact on the final product's quality and performance. Firstly, steel billets are visually inspected to identify any surface defects or irregularities. This includes checking for cracks, surface oxidation, or any other visible abnormalities that could affect the dimensions. This visual inspection is often conducted by trained personnel who have an eye for detail and can identify even the smallest imperfections. After the visual inspection, the billets undergo dimensional measurement using various tools and instruments. One commonly used tool is a caliper, which is used to measure the length, width, and height of the billet. The measurements are compared against the specified dimensions to ensure they fall within the acceptable range. Any deviations beyond the tolerance limit are flagged for further investigation. In addition to calipers, other tools such as micrometers, height gauges, and coordinate measuring machines (CMM) may also be used to measure specific dimensions or features of the billet. These instruments provide more accurate and precise measurements, especially for critical dimensions that require a higher level of precision. Furthermore, non-destructive testing techniques are employed to assess the internal quality and dimensional accuracy of the billets. Ultrasonic testing, for instance, uses high-frequency sound waves to detect any internal defects or inconsistencies that may affect the dimensions. This method can identify hidden flaws such as voids, inclusions, or discontinuities, providing a comprehensive assessment of the billet's dimensional accuracy. Overall, steel billets are inspected for dimensional accuracy through a combination of visual inspections, dimensional measurements using various tools, and non-destructive testing techniques. By conducting these inspections, manufacturers ensure that the billets meet the required specifications, leading to high-quality final products.

Send your message to us

Z39 BMP Rolled Steel Coil Construction Roofing Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords