Fiberglass Mat Tissue Woven Roving Combo Mat 900gsm,1600/2400

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Process

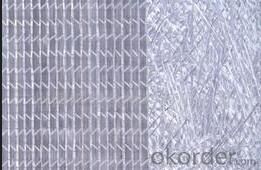

Fiberglass stitch combo mat is the mat combining the woven roving and a even layer of chopped strand mat with polyester yarn.

Properties

• Fiber level unfolded without cross, high density, high utilizing rate.

• Multi-layer finished one time, decrease layer and enhance efficiency.

• Providing the product with multi-directional mechanical strength.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Specifications

specifications | Fibre type | Wover roving | Chopped strand | Overall weight | Width |

(g/㎡) | (g/㎡) | (g/㎡) | (mm) | ||

EMK 600/300 | E-Glass | 600 | 300 | 900 | 1600/2400 |

EMK 600/380 | E-Glass | 600 | 380 | 980 | 1600/2400 |

EMK 600/450 | E-Glass | 600 | 450 | 1050 | 1600/2400 |

EMK 800/300 | E-Glass | 800 | 300 | 1100 | 1600/2400 |

EMK 800/380 | E-Glass | 800 | 380 | 1180 | 1600/2400 |

EMK 800/450 | E-Glass | 800 | 450 | 1250 | 1600/2400 |

Packaging: Wrapped in PVC and placed within a cardboard carton. | |||||

- Q: Can fiberglass mat tissue be used for pipe insulation?

- Yes, fiberglass mat tissue can be used for pipe insulation. It provides thermal insulation and can help prevent heat loss or gain in pipes. Additionally, it offers excellent resistance to moisture and corrosion, making it suitable for various pipe insulation applications.

- Q: Can fiberglass mat tissue be used for making lightweight panels?

- Yes, fiberglass mat tissue can be used for making lightweight panels. It is often used as a reinforcement material in composite panels, providing strength and durability while keeping the overall weight of the panels low.

- Q: What is the expected lifespan of fiberglass mat tissue?

- The expected lifespan of fiberglass mat tissue can vary depending on various factors such as the quality of the material, the environment it is exposed to, and how well it is maintained. However, on average, fiberglass mat tissue can have a lifespan of around 20 to 30 years.

- Q: Can fiberglass mat tissue be used for ceiling insulation?

- Ceiling insulation requires specific materials that are more suitable and effective, such as fiberglass batts, cellulose, or foam insulation. These materials are designed to provide thermal resistance and reduce heat transfer between the interior and exterior of a building. Using fiberglass mat tissue for ceiling insulation is not recommended as it is not designed for insulation purposes. It is commonly used in construction applications like reinforcing plaster or other building materials, but it lacks the necessary thickness to effectively insulate ceilings. In addition, fiberglass insulation materials can pose safety risks as they release airborne particles and fibers that can be harmful if inhaled. Therefore, it is crucial to use insulation materials specifically engineered for ceiling insulation to ensure energy efficiency, comfort, and safety in your home or building.

- Q: How is fiberglass mat tissue used in the production of composite panels?

- Fiberglass mat tissue is commonly used in the production of composite panels due to its unique properties and versatility. It serves as a reinforcement material that helps enhance the strength, durability, and overall performance of the composite panels. In the production process, fiberglass mat tissue is typically sandwiched between layers of resin to create a composite structure. The tissue acts as a reinforcing layer, providing additional strength and stability to the panels. It helps distribute the stress applied to the panel evenly, reducing the risk of cracks or fractures. One of the key advantages of using fiberglass mat tissue is its ability to improve the impact resistance of composite panels. The tissue absorbs and disperses energy when subjected to external forces, minimizing the risk of damage or breakage. This makes it an ideal choice for applications that require high impact resistance, such as automotive parts, boat hulls, or aircraft components. Fiberglass mat tissue also offers excellent corrosion resistance, making it suitable for use in environments with high humidity or exposure to chemicals. It acts as a barrier that protects the composite panels from moisture and corrosive substances, extending their lifespan and ensuring their long-term performance. Additionally, fiberglass mat tissue is highly moldable, allowing for the creation of complex shapes and designs. It can be easily molded into various forms, providing flexibility in the production process and enabling the creation of customized composite panels for specific applications. Overall, fiberglass mat tissue plays a crucial role in the production of composite panels by reinforcing the structure, enhancing impact resistance, improving corrosion resistance, and enabling flexibility in design. Its unique properties make it a popular choice in industries such as construction, transportation, aerospace, and marine, where high-performance and durable composite panels are required.

- Q: Can fiberglass mat tissue be used for repairing fiberglass boats?

- Yes, fiberglass mat tissue can be used for repairing fiberglass boats. Fiberglass mat tissue is a versatile material that is commonly used in repairing and reinforcing fiberglass structures, including boats. It is designed to provide strength and durability, making it an ideal choice for patching holes, cracks, or damaged areas in fiberglass boat hulls. The mat tissue is typically layered with resin to form a solid and stable repair, ensuring that the boat remains structurally sound. Additionally, fiberglass mat tissue is easy to work with and can be cut to the desired size and shape, making it suitable for various repair applications on fiberglass boats.

- Q: Does fiberglass mat tissue require any special precautions during transportation?

- Yes, fiberglass mat tissue does require special precautions during transportation. Fiberglass mat tissue is a delicate material that can easily get damaged if not handled properly. Therefore, it is important to take certain precautions to ensure its safe transportation. Firstly, the fiberglass mat tissue should be packed in a sturdy and durable packaging material that can protect it from any external impacts or vibrations. This can be achieved by using heavy-duty cardboard boxes or wooden crates that provide adequate cushioning and support. Additionally, it is crucial to label the packaging clearly as "Fragile" or "Handle with Care" to alert the handlers about the delicate nature of the product. This will help prevent any mishandling or rough treatment during transportation. Furthermore, fiberglass mat tissue should be stored and transported in an upright position to minimize the risk of any bending or folding that could potentially damage the material. It is also important to avoid stacking heavy objects on top of the fiberglass mat tissue to prevent any unnecessary pressure or crushing. Lastly, it is advisable to use secure and reliable transportation services that have experience in handling delicate materials like fiberglass mat tissue. This ensures that the product is transported with utmost care and attention, reducing the chances of any damage during transit. By following these special precautions, the risk of damage to the fiberglass mat tissue during transportation can be significantly minimized, ensuring that it reaches its destination in perfect condition.

- Q: What are the recommended storage and handling practices for fiberglass mat tissue?

- To ensure the integrity and longevity of fiberglass mat tissue, it is necessary to adhere to a few recommended practices. 1. Storage: Fiberglass mat tissue should be stored in a clean, dry environment to prevent damage from moisture or dirt. Ideally, it should be kept indoors, away from direct sunlight and extreme temperatures. 2. Handling: Proper handling is crucial to avoid damaging the delicate material. It is advisable to wear protective gloves and safety glasses to prevent injuries. Care should be taken to handle it gently, avoiding any tears or creases that may compromise its performance. 3. Transportation: During transportation, it is essential to pack fiberglass mat tissue securely to minimize the risk of damage. Adequate protection should be provided to prevent impact or vibration. If possible, it is preferable to transport it in a dedicated vehicle or container for added safety. 4. Avoid chemical contact: Fiberglass mat tissue should not come into contact with chemicals such as acids, alkalis, or solvents. These substances can degrade and weaken the material. Clean hands should be used when handling, and contact with harmful substances should be avoided. 5. Follow manufacturer's guidelines: It is advisable to adhere to the specific recommendations provided by the manufacturer regarding storage and handling. Different manufacturers may have slightly different requirements, and following them ensures optimal performance and longevity. By adhering to these recommended practices for storage and handling, the integrity of fiberglass mat tissue can be maintained, guaranteeing its readiness for its intended use.

- Q: What is the expected lifespan of fiberglass mat tissue in cleanroom applications?

- Several factors can influence the expected lifespan of fiberglass mat tissue in cleanroom applications. The durability and long-lasting properties of fiberglass mat tissue are well-known in cleanrooms. However, variables such as contamination level, cleaning procedures, maintenance practices, and overall cleanroom conditions can impact its lifespan. By providing proper care and regular maintenance, fiberglass mat tissue can typically endure for several years in cleanroom applications. Extending its lifespan can be achieved through frequent cleaning and replacing any damaged or contaminated sections. Following the manufacturer's guidelines and recommendations for cleaning and maintenance is crucial to ensure optimal performance and longevity. Furthermore, the expected lifespan of fiberglass mat tissue can also be influenced by its quality and grade. Higher-quality materials exhibit greater resilience and can withstand environmental stressors better than lower-grade options. Therefore, investing in high-quality fiberglass mat tissue can contribute to a longer lifespan in cleanroom applications. To summarize, there is no definitive answer regarding the exact expected lifespan of fiberglass mat tissue in cleanroom applications. However, regular maintenance, proper care, and the use of high-quality materials can significantly increase its longevity.

- Q: How does the fiber content of fiberglass mat tissue affect its strength?

- The strength of fiberglass mat tissue is directly influenced by its fiber content. As the fiber content increases, the strength of the tissue also increases. This is because the fibers provide the necessary structural integrity and reinforcement to the material. When the fiber content is raised, it results in a greater concentration of fibers, thereby boosting the overall strength of the tissue. Fiberglass mat tissue is comprised of randomly oriented glass fibers that are bound together with a resin binder. These fibers are responsible for carrying the load and resisting any external forces or stresses applied to the material. Consequently, the more fibers present in the tissue, the higher the load-carrying capacity and strength of the material. Moreover, a higher fiber content enhances the stiffness of the fiberglass mat tissue. Stiffness refers to the material's ability to resist deformation or bending under applied loads. With a larger quantity of fibers, the tissue becomes stiffer, making it less susceptible to bending or flexing. This increased stiffness contributes significantly to the overall strength of the material. It is important to note that while a higher fiber content improves the strength of fiberglass mat tissue, there is an optimal range where the benefits of additional fibers are maximized. Beyond this range, increasing the fiber content may not result in a substantial improvement in strength, and it may begin to have diminishing returns. Therefore, striking the right balance between fiber content and strength is crucial for specific applications. In conclusion, the strength of fiberglass mat tissue is directly affected by its fiber content. Increasing the fiber content leads to a higher concentration of fibers, thereby enhancing the material's load-carrying capacity and stiffness. Finding the optimal fiber content is essential for maximizing the strength of the tissue in specific applications.

Send your message to us

Fiberglass Mat Tissue Woven Roving Combo Mat 900gsm,1600/2400

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords