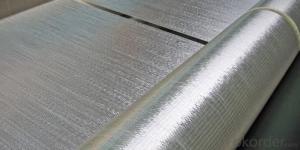

Fiberglass Unidirectional Fabric with Density 1000gsm Width 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Unidirectional Fabric

Description:

Glassfiber unidirectional fabricis an unwoven fabrics consisting of randomly distributed chopped strands held together with Emulsion Binder.Emulsion Binder Chopped Strand Mats are compatible with unsaturated polyester, vinyl ester, phenol and epoxy resins.

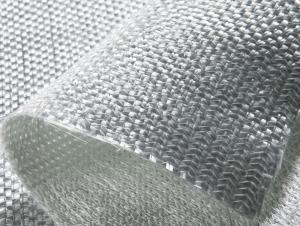

Properties

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Inages:

Properties

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

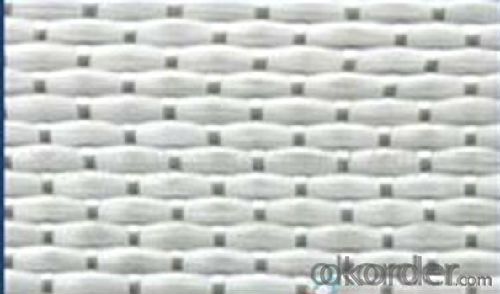

Specifications

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

FAQ

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is 2 pallets.

- Q: Can fiberglass mat tissue be used for lightweight construction?

- Yes, fiberglass mat tissue can be used for lightweight construction. Fiberglass mat tissue is a thin and lightweight material made up of randomly oriented glass fibers bonded together with a binder. It is commonly used as a reinforcement material in composite laminates and is known for its excellent strength-to-weight ratio. In lightweight construction, where weight reduction is a key consideration, fiberglass mat tissue can be an ideal choice. Its low weight adds minimal additional load to the structure while still providing sufficient strength and durability. The random orientation of the fibers in the mat tissue ensures that the load is evenly distributed, further enhancing its strength properties. Additionally, fiberglass mat tissue is easy to handle and can be easily molded into various shapes and forms. This flexibility makes it suitable for applications in lightweight construction, such as in the production of lightweight panels, wall partitions, and roof structures. The material can also be used in combination with other lightweight materials, such as foam cores or honeycomb structures, to further enhance its lightweight properties. Overall, fiberglass mat tissue is a versatile material that can be effectively used for lightweight construction. Its lightweight nature, combined with its strength and durability, make it a suitable choice for various applications where weight reduction is a priority.

- Q: Can fiberglass mat tissue be used for acoustic insulation?

- Yes, fiberglass mat tissue can be used for acoustic insulation. Fiberglass mat tissue is a lightweight material that has excellent sound absorption properties. It can effectively absorb and dampen sound waves, reducing noise and improving the acoustic environment. Fiberglass mat tissue is commonly used in the construction industry for insulating walls, ceilings, and floors to reduce noise transmission. It is also used in automotive applications and other industries where sound insulation is required. Its high porosity and fibrous structure make it an ideal material for absorbing and attenuating sound waves, making it suitable for acoustic insulation.

- Q: Is fiberglass mat tissue suitable for insulation in wastewater treatment plants?

- Yes, fiberglass mat tissue is suitable for insulation in wastewater treatment plants. Wastewater treatment plants often require insulation to prevent heat loss, control temperature, and protect against corrosion. Fiberglass mat tissue is a commonly used material for insulation in these facilities due to its high thermal resistance, excellent chemical resistance, and durability. It can effectively insulate pipes, tanks, and other equipment in wastewater treatment plants, ensuring optimal performance and energy efficiency. Additionally, fiberglass mat tissue is lightweight, easy to install, and cost-effective, making it a practical choice for insulation in these harsh environments.

- Q: Can fiberglass mat tissue be used for waterproofing?

- Indeed, fiberglass mat tissue has the potential to be utilized for waterproofing purposes. This particular material, comprised of fiberglass fibers, takes the form of a thin, non-woven substance. Its primary function lies in the reinforcement and provision of waterproofing attributes within the realm of construction and building applications. When combined with a waterproofing agent or resin, the fiberglass mat tissue can establish an impermeable barrier, effectively impeding the infiltration of water or moisture. Consequently, it proves to be a highly advantageous option for various undertakings such as roofing, basement waterproofing, and the installation of bathrooms or showers. Furthermore, the robustness and enduring nature of fiberglass mat tissue contribute to its resistance against cracks or tears, guaranteeing the longevity of its waterproofing capabilities.

- Q: Is fiberglass mat tissue suitable for insulation in sports facilities?

- Sports facilities can benefit from the use of fiberglass mat tissue for insulation. Fiberglass is a widely utilized material for insulation because of its outstanding thermal properties and fire resistance. It effectively insulates, maintaining a comfortable indoor environment by preventing heat loss or gain. Moreover, fiberglass insulation is lightweight, sturdy, and simple to install, which makes it perfect for sports facilities that require insulation across large areas. It is also resistant to moisture and does not encourage the growth of mold or mildew, guaranteeing a healthy and sanitary atmosphere. All things considered, fiberglass mat tissue is a dependable and effective choice for insulating sports facilities.

- Q: Are there any specific certifications or standards that fiberglass mat tissue must meet?

- Certifications and standards are necessary to guarantee the quality and appropriateness of fiberglass mat tissue for different purposes. The ASTM D 4601 standard is widely recognized and specifies the minimum requirements for glass fiber mats used in roofing and waterproofing systems. It covers various physical properties like weight, thickness, tensile strength, tear resistance, and water resistance. Apart from ASTM D 4601, fiberglass mat tissue may undergo testing based on its intended usage. For example, if it is used in the automotive industry, it may need to meet ISO 9001 or IATF 16949 standards, ensuring quality management systems and product consistency. Furthermore, fiberglass mat tissue used in construction or building materials should adhere to regulations set by organizations like the International Code Council (ICC), the American National Standards Institute (ANSI), or the Underwriters Laboratories (UL). These standards primarily focus on fire resistance, thermal insulation properties, and overall safety. Ultimately, the specific certifications and standards that fiberglass mat tissue must meet depend on its intended application and the industry it is used in. These standards are pivotal in ensuring the quality, performance, and safety of fiberglass mat tissue products.

- Q: Is fiberglass mat tissue resistant to mold and mildew?

- Yes, fiberglass mat tissue is resistant to mold and mildew due to its non-porous and moisture-resistant properties.

- Q: What is the chemical resistance of fiberglass mat tissue?

- The excellent chemical resistance of fiberglass mat tissue stems from the inherent properties of the fiberglass material. Typically, the mat tissue consists of woven or bound glass fibers, forming a protective barrier against a diverse array of chemicals. The glass fibers themselves possess a high resistance to corrosion, rendering fiberglass mat tissue suitable for use in environments where chemical exposure is a concern. The chemical resistance of fiberglass mat tissue can vary based on the specific resin or binder used in the manufacturing process. Various types of resins may offer superior resistance to certain chemicals, while others may be more susceptible to degradation. It is crucial to consider the specific chemicals that will come into contact with the fiberglass mat tissue and choose a compatible resin or binder accordingly. In general, fiberglass mat tissue is renowned for its ability to withstand acids, alkalis, solvents, and other commonly found industrial and commercial chemicals. It can endure exposure to a wide range of corrosive substances, making it a versatile and long-lasting material for various applications. Nevertheless, it is important to note that prolonged exposure to highly concentrated or aggressive chemicals may eventually result in some degradation or deterioration of the fiberglass mat tissue. Therefore, it is imperative to consult the manufacturer's specifications and guidelines to ensure proper chemical compatibility and performance in specific environments.

- Q: Can fiberglass mat tissue be used for making insulation boards?

- Fiberglass mat tissue is indeed a viable option for the production of insulation boards. This lightweight and flexible material is frequently employed in the creation of insulation boards. It boasts exceptional thermal insulation capabilities, as well as the ability to absorb sound and resist fire. The process of layering and compressing the mat tissue is typically employed to manufacture these insulation boards, resulting in a robust and efficient barrier against heat transfer. Furthermore, fiberglass mat tissue is impervious to moisture, mold, and pests, making it a trustworthy choice for insulation purposes. In summary, the insulation performance, durability, and resistance to environmental elements make fiberglass mat tissue a suitable choice for the construction of insulation boards.

- Q: Can fiberglass mat tissue be used for interior decoration?

- Fiberglass mat tissue is an excellent option for interior decoration. This versatile material serves multiple purposes and is commonly utilized as a reinforcement for composite materials like fiberglass reinforced plastic (FRP). These materials are often employed to create decorative elements such as panels, wall coverings, and moldings. The fiberglass mat tissue offers a lightweight and durable solution with exceptional strength and resistance to moisture and chemicals. Moreover, it can be easily molded into various shapes and designs, making it a favored choice for interior decoration projects. Furthermore, the fiberglass mat tissue can be coated or painted to match any desired color or texture, enabling a wide array of creative possibilities in interior design.

Send your message to us

Fiberglass Unidirectional Fabric with Density 1000gsm Width 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords