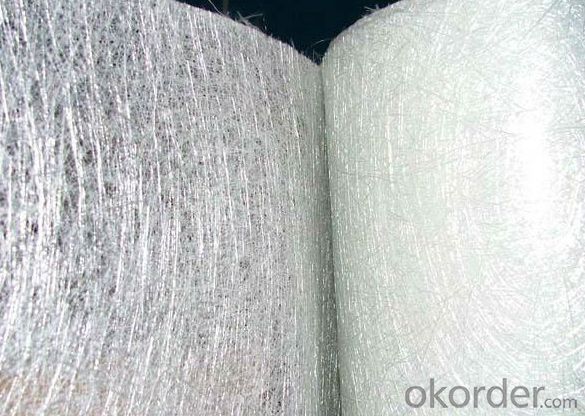

Fiberglass Mat Tissue Chopped Strand Mat 450gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Fiberglass Chopped Strand Mat is an non-woven E- or C-glass fiberglass fabric manufactured by spreading continuous filament rovings of 50mm in length randomly and uniformly in combination with polyester binder in power form (or other binder in emulsion form).

2.Main Features

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moudings, such as, various sheets and penels, boat hulls, boat tubs, cooling towers, corrosion resistand, vehicles, etc.

3.Specifications

Glass type: E-glass and C-glass Chopped Strand Mat.

Bond type: Powder or Emulsion.

Density: 80g/m2-900g/m2.

Normal types : 180g/m2. 225g/m2. 300g/m2 450g/m2. 600m2.

Bond Content: 100g/m2 (10%-15%). 300g/m2.450g/m2.600g/m2 (4%-6%)

Roll Width: 200mm-2600mm.

Normal types :750mm.1040mm.1250mm.1270mm.1450mm.

Roll weight/: 28kgs-55kgs.

Normal types :28kgs.30kgs.35kgs.

4.FAQ

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

Images

- Q: Can fiberglass mat tissue be used for insulating concrete forms (ICFs)?

- Fiberglass mat tissue is indeed suitable for insulating concrete forms (ICFs). By acting as a reinforcement layer, it can be directly applied to the surface of ICFs. Its primary function is to enhance the strength and durability of the concrete, while simultaneously improving the insulation properties of the ICF system. To secure the fiberglass mat tissue to the ICF surface, it is typically embedded in a thin layer of adhesive or mortar. This combination of materials creates a robust and insulated barrier that effectively reduces heat loss and enhances energy efficiency in buildings. Moreover, the lightweight and easy-to-handle nature of fiberglass mat tissue makes it a convenient choice for ICF installations.

- Q: Does fiberglass mat tissue require any special maintenance after installation?

- After the installation of fiberglass mat tissue, it typically does not require any special maintenance. Fiberglass mat tissue is designed to be durable and resistant to wear and tear. It is also highly resistant to moisture, chemicals, and UV radiation, making it suitable for various applications such as roofing, insulation, and wall covering. However, it is recommended to inspect the fiberglass mat tissue periodically to ensure it remains in good condition. This can involve checking for any signs of damage, such as cracks, tears, or delamination. If any issues are found, they should be addressed promptly to prevent further damage. Additionally, it is important to follow the manufacturer's guidelines and recommendations for the specific type of fiberglass mat tissue used. This may include avoiding exposure to certain chemicals or using appropriate cleaning methods if necessary. Overall, while fiberglass mat tissue is generally low-maintenance, regular inspections and adherence to manufacturer's guidelines can help ensure its longevity and optimal performance.

- Q: How long does fiberglass mat tissue typically last?

- The lifespan of fiberglass mat tissue can vary depending on various factors such as the quality of the material, its exposure to environmental conditions, and the level of maintenance. On average, fiberglass mat tissue can last anywhere from 20 to 30 years. However, with proper installation and regular upkeep, it is possible for it to last even longer. It is important to note that regular inspection and maintenance can help identify any signs of wear or damage, allowing for timely repairs or replacements to ensure its longevity.

- Q: Can fiberglass mat tissue be used in high-temperature applications?

- No, fiberglass mat tissue is not suitable for high-temperature applications.

- Q: Can fiberglass mat tissue be used for making furniture?

- No, fiberglass mat tissue is not suitable for making furniture. It is primarily used in composite materials and construction applications, not for furniture manufacturing.

- Q: What is the thermal resistance of fiberglass mat tissue?

- The thermal resistance of fiberglass mat tissue is determined by several factors, including the mat's thickness, fiber density, and the inclusion of additional materials or coatings. In general, fiberglass exhibits low thermal resistance, signifying its excellent heat conductivity. Nevertheless, when employed as insulation, the thickness and density of the fiberglass mat can elevate its thermal resistance, enhancing its ability to reduce heat transfer. It is crucial to acknowledge that precise thermal resistance values may differ based on the product and application, hence it is advisable to consult the manufacturer's specifications for precise information.

- Q: Can fiberglass mat tissue be used for reinforcing swimming pools?

- Yes, fiberglass mat tissue can be used for reinforcing swimming pools. It is commonly used in the construction of pool shells to provide added strength and durability.

- Q: Can fiberglass mat tissue be used for insulation in cleanrooms?

- Yes, fiberglass mat tissue can be used for insulation in cleanrooms. It is a commonly used material due to its excellent thermal insulation properties, low cost, and high resistance to chemicals and moisture. Additionally, fiberglass mat tissue has low particulate emission, making it suitable for cleanroom environments where maintaining a controlled and sterile atmosphere is crucial.

- Q: How is fiberglass mat tissue used in the automotive industry?

- Fiberglass mat tissue is extensively used in the automotive industry for various purposes. It is a versatile material that offers numerous benefits, making it an ideal choice for several applications. One of the primary uses of fiberglass mat tissue in the automotive industry is for reinforcing composite materials. It is commonly used as a reinforcement layer in the manufacturing of parts such as car panels, hoods, roofs, and doors. The fiberglass mat tissue enhances the structural integrity of these components, making them more robust and resistant to impact and external forces. This reinforcement property helps in improving the overall safety of the vehicle. Additionally, fiberglass mat tissue is also used in the automotive industry for sound insulation purposes. The material has excellent sound absorption properties, which helps in reducing noise and vibrations within the vehicle. By installing fiberglass mat tissue in various areas such as the floor, doors, and roof, automakers can significantly enhance the overall acoustic comfort of the vehicle, providing a quieter and more enjoyable driving experience. Furthermore, fiberglass mat tissue is also utilized in the automotive industry for thermal insulation. The material acts as a barrier against heat transfer, helping to regulate the temperature inside the vehicle. By incorporating fiberglass mat tissue in areas such as the engine compartment, exhaust system, and undercarriage, automakers can effectively insulate the vehicle from excessive heat, preventing overheating and ensuring optimal performance. In summary, fiberglass mat tissue is extensively used in the automotive industry for reinforcement, sound insulation, and thermal insulation purposes. Its versatile properties make it an indispensable material in the manufacturing of vehicles, contributing to improved safety, comfort, and performance.

- Q: Can fiberglass mat tissue be used for repairing fiberglass canoes?

- Yes, fiberglass mat tissue can be used for repairing fiberglass canoes. It is commonly used to reinforce and strengthen the damaged areas of the canoe by providing additional structural support.

Send your message to us

Fiberglass Mat Tissue Chopped Strand Mat 450gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords