Fiberglass Mat Tissue Glass Wool Heat Insulation, Sound Proof, and Fireproof Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Glass wool sention pipe is a kind of economical insulating material which is light and easy to install. This material has excellent performance of heat and sound insulation under both extremely high and low temperature conditions. Therefore, ventilating ducts, industrial civial heat suppling and all kinds of heating, cooling pipelines.

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property.

2.Main features of Glass Wool Blanket:

1) Heat insulation and heat preservation, sound adsorption and noise reduction

2) Low slag indusion content, thin and long inner fiber

3) Thermal stability, stable and high efficiency for a long time

4) High temperature heat-stability, durability, high temperature shrinkage resistance

5) Damp proof property, with the hydrophobicity are not less than 98%

6) Excellent fire proof performance, European standard non-flammable class A material

7) Non-poison, not contain rock wool and doesn't grow the mould etc.

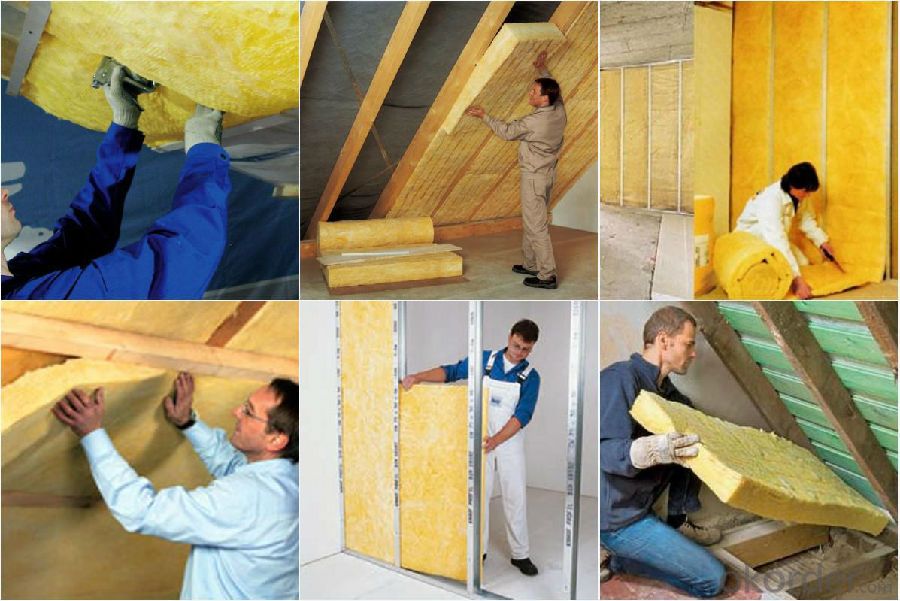

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue suitable for insulation in cold storage facilities?

- Yes, fiberglass mat tissue is suitable for insulation in cold storage facilities. It offers excellent thermal insulation properties and is commonly used in such environments to maintain low temperatures and prevent heat transfer. Additionally, fiberglass is resistant to moisture, which is important in cold storage facilities where condensation can occur.

- Q: How is fiberglass mat tissue used in the construction industry?

- Fiberglass mat tissue is widely used in the construction industry for various applications. This material is made up of thin strands of glass fibers that are bonded together with a resin. It offers several properties that make it suitable for construction purposes. One common use of fiberglass mat tissue is in the production of roofing materials. It is often used as a reinforcement layer in roofing shingles or sheets. The fiberglass mat tissue adds strength and durability to the roof, making it more resistant to weather elements such as wind, rain, and hail. Additionally, it helps to prevent cracking and splitting, prolonging the lifespan of the roofing material. Another application of fiberglass mat tissue in the construction industry is in the production of composite materials. It is commonly used as a reinforcement layer in composite panels and boards. The fiberglass mat tissue enhances the strength and stiffness of the composite material, making it suitable for various structural applications. It is also lightweight, which makes it an ideal choice for building materials that require both strength and reduced weight. Fiberglass mat tissue is also used in the construction of walls and ceilings. It can be applied as a layer between the gypsum board and the insulation material to provide additional strength and resistance to impacts. This helps to prevent cracks and damage to the walls or ceilings, enhancing the overall structural integrity of the building. Furthermore, fiberglass mat tissue finds application in the construction of pipes and tanks. It is used as a reinforcement layer in the manufacturing of fiberglass-reinforced plastic (FRP) pipes and tanks. The fiberglass mat tissue adds strength and rigidity to the FRP structure, making it suitable for various industrial applications, including chemical processing, wastewater treatment, and oil and gas industries. In conclusion, fiberglass mat tissue is widely used in the construction industry for its strength, durability, and lightweight properties. It is utilized in roofing materials, composite panels, walls, ceilings, pipes, and tanks, among other applications. Its versatility and performance make it a preferred choice among construction professionals for enhancing the structural integrity of various building components.

- Q: How is fiberglass mat tissue used in the production of printed circuit boards?

- Fiberglass mat tissue is a commonly utilized reinforcement material in the production of printed circuit boards (PCBs). PCBs, consisting of copper layers, insulating materials, and fiberglass, are typically made in this way. The purpose of the fiberglass mat tissue is to provide structural support and mechanical strength to the PCB. Throughout the manufacturing process, the fiberglass mat tissue is saturated with epoxy resin, which forms a laminate material. This laminate is then combined with copper foils, serving as conductive pathways for the electrical signals on the PCB. The role of the fiberglass mat tissue in the performance and reliability of the PCB is crucial. It establishes a firm foundation for the copper layers, preventing delamination or warping due to mechanical stress or temperature fluctuations. Furthermore, it helps maintain the PCB's dimensional stability, ensuring its flatness and rigidity. Additionally, the fiberglass mat tissue enhances the PCB's resistance to heat and moisture. The epoxy resin used in the laminate provides excellent insulation properties, shielding the copper conductors from short circuits and electrical leakage. Furthermore, the fiberglass mat tissue acts as a barrier against moisture absorption, safeguarding the PCB from damage or malfunctions. In conclusion, fiberglass mat tissue is an indispensable element in the production of printed circuit boards. It offers structural support, improves mechanical strength, ensures dimensional stability, and enhances resistance to heat and moisture. Ultimately, the use of fiberglass mat tissue contributes to the overall reliability and performance of PCBs in various electronic devices.

- Q: Is fiberglass mat tissue suitable for insulation in chemical processing plants?

- Yes, fiberglass mat tissue is suitable for insulation in chemical processing plants. It is highly resistant to corrosion and chemicals, making it an ideal choice for such environments. Additionally, fiberglass mat tissue offers excellent thermal insulation properties, helping to maintain optimal temperature levels in the plant.

- Q: Does fiberglass mat tissue require any special precautions during transportation?

- Yes, fiberglass mat tissue does require special precautions during transportation. It should be handled with care to avoid any damage or breakage as it can easily tear or become compromised. It is advisable to use proper packaging and secure the material to prevent movement or shifting during transportation. Additionally, protective measures such as wearing gloves, masks, and safety glasses should be taken to avoid any potential irritation or respiratory discomfort caused by the fiberglass fibers.

- Q: Does fiberglass mat tissue provide any thermal insulation?

- Indeed, thermal insulation is provided by fiberglass mat tissue. The reason lies in the fact that fiberglass possesses a low heat conductivity, impeding the effortless transfer of heat. As a mat tissue, it successfully captures air within its fibers, thereby generating an insulation layer. This layer serves as a shield against heat transfer via conduction and diminishes the loss of thermal energy. Consequently, fiberglass mat tissue proves to be a viable remedy for achieving thermal insulation in numerous sectors, including construction, automotive, and aerospace industries.

- Q: What is the moisture absorption rate of fiberglass mat tissue?

- The moisture absorption rate of fiberglass mat tissue is relatively low, as fiberglass is known for its water-resistant properties.

- Q: Does fiberglass mat tissue provide any acoustic insulation?

- Fiberglass mat tissue does provide some degree of acoustic insulation. Due to its fibrous structure, it can absorb sound waves and reduce their transmission through walls or other surfaces. However, it is important to note that the level of acoustic insulation provided by fiberglass mat tissue may vary depending on various factors such as thickness, density, and the specific application. In some cases, additional layers or thicker materials may be required to achieve optimal acoustic insulation.

- Q: What is the composition of fiberglass mat tissue?

- Fiberglass mat tissue, also referred to as fiberglass mat or fiberglass veil, comprises a blend of fiberglass fibers and a binder substance. The fiberglass fibers utilized in its formulation are typically derived from silica, a naturally occurring mineral, and are esteemed for their exceptional strength and durability. The specific binder substance used in fiberglass mat tissue can differ, but commonly includes materials like urea-formaldehyde, acrylic, or polyester resins. The binder's function is to secure the fiberglass fibers together and provide the mat with structural integrity. Furthermore, the composition of fiberglass mat tissue may incorporate additional additives. These additives may encompass pigments, fire retardants, or coatings, contingent upon the mat's intended application and desired properties. In conclusion, fiberglass mat tissue is an amalgamation of fiberglass fibers and a binder substance, supplemented by other additives as required. This composition enables the material to possess remarkable strength, flexibility, and resistance to diverse environmental factors, rendering it a versatile substance employed in numerous industries including construction, automotive, aerospace, and marine.

- Q: Can fiberglass mat tissue be used in corrosive environments?

- No, fiberglass mat tissue is not suitable for use in corrosive environments as it is not resistant to corrosion.

Send your message to us

Fiberglass Mat Tissue Glass Wool Heat Insulation, Sound Proof, and Fireproof Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords