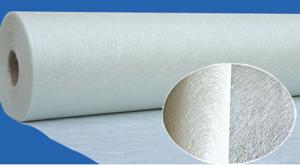

Fiberglass Mat Tissue Fiberglass Woven Roving Combo Mat 1050gsm, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Process

Fiberglass stitch combo mat is the mat combining the woven roving and a even layer of chopped strand mat with polyester yarn.

Properties

• Fiber level unfolded without cross, high density, high utilizing rate.

• Multi-layer finished one time, decrease layer and enhance efficiency.

• Providing the product with multi-directional mechanical strength.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Specifications

specifications | Fibre type | Wover roving | Chopped strand | Overall weight | Width |

(g/㎡) | (g/㎡) | (g/㎡) | (mm) | ||

EMK 600/300 | E-Glass | 600 | 300 | 900 | 1600/2400 |

EMK 600/380 | E-Glass | 600 | 380 | 980 | 1600/2400 |

EMK 600/450 | E-Glass | 600 | 450 | 1050 | 1600/2400 |

EMK 800/300 | E-Glass | 800 | 300 | 1100 | 1600/2400 |

EMK 800/380 | E-Glass | 800 | 380 | 1180 | 1600/2400 |

EMK 800/450 | E-Glass | 800 | 450 | 1250 | 1600/2400 |

Packaging: Wrapped in PVC and placed within a cardboard carton. | |||||

- Q: What is the impact resistance of fiberglass mat tissue at high temperatures?

- The impact resistance of fiberglass mat tissue at high temperatures is generally quite good. The fiberglass material offers excellent strength and durability, allowing it to maintain its structural integrity even when exposed to elevated temperatures. However, it is important to note that the specific impact resistance can vary depending on factors such as the thickness and composition of the fiberglass mat tissue. Overall, fiberglass mat tissue is known for its ability to withstand impacts and maintain its performance even under high temperature conditions.

- Q: How does fiberglass mat tissue compare to other insulation materials?

- Fiberglass mat tissue, as an insulation material, offers numerous advantages over its counterparts. Primarily, it possesses exceptional thermal insulation properties, effectively preventing the transfer of heat and maintaining indoor temperatures at a comfortable level. This quality is particularly significant in extreme climates, where the building envelope may be susceptible to extreme cold or heat. Furthermore, fiberglass mat tissue exhibits resistance to moisture, mold, and mildew, which contributes to its longevity and durability as an insulation option. Its inability to absorb water prevents the growth of mold and the deterioration of the material over time. This attribute proves especially advantageous in areas with high humidity or a propensity for moisture accumulation, such as basements or bathrooms. In addition, fiberglass mat tissue is non-combustible and possesses a high fire resistance rating. Consequently, it serves as a safe choice for insulation, limiting the spread of flames in the event of a fire. It also acts as a barrier, impeding the fire from extending to other sections of the building and granting occupants valuable time for evacuation. Regarding installation, fiberglass mat tissue is relatively easy to handle and install. It can be conveniently cut to fit any desired shape or size, allowing for flexibility during the installation process. Its versatility is further evident in its applicability to walls, floors, ceilings, and roofs. Lastly, fiberglass mat tissue stands as an environmentally friendly option. It is manufactured from recycled glass and sand, reducing waste and conserving precious natural resources. Moreover, it remains recyclable at the conclusion of its lifespan, further minimizing its environmental impact. Overall, the exceptional thermal insulation properties, durability, moisture and fire resistance, ease of installation, and environmental sustainability of fiberglass mat tissue position it as a highly favorable choice in comparison to alternative insulation materials.

- Q: How does fiberglass mat tissue perform in high temperatures?

- Fiberglass mat tissue performs well in high temperatures as it has a high melting point and excellent heat resistance. It retains its strength and structural integrity even when exposed to elevated temperatures, making it suitable for various applications in high-temperature environments.

- Q: What is the moisture vapor transmission rate of fiberglass mat tissue?

- The moisture vapor transmission rate of fiberglass mat tissue can vary depending on its specific composition and manufacturing process. It is typically low, as fiberglass is known for its moisture resistance properties.

- Q: Can fiberglass mat tissue be used for repairing fiberglass kayaks?

- Yes, fiberglass mat tissue can be used for repairing fiberglass kayaks. Fiberglass mat tissue is a lightweight material that is commonly used in the repair and reinforcement of fiberglass products, including kayaks. It is designed to be easily moldable and conform to the shape of the damaged area. By applying the fiberglass mat tissue with an epoxy resin, it can effectively reinforce and bond the damaged sections of a fiberglass kayak, restoring its strength and durability. It is important to ensure that the damaged area is properly prepared and the fiberglass mat tissue is applied correctly to achieve a strong and long-lasting repair.

- Q: Can fiberglass mat tissue be used for making furniture?

- No, fiberglass mat tissue is not typically used for making furniture. Fiberglass mat tissue is a lightweight material that is commonly used in industries such as construction, automotive, and aerospace for its strength and durability. It is often used as a reinforcement material in the production of composite materials, such as fiberglass-reinforced plastic (FRP) or fiberglass-reinforced polymers (FRPs). While fiberglass may offer some advantages in terms of strength and resistance to moisture, it is not a commonly used material in furniture manufacturing. Furniture typically requires materials that are aesthetically pleasing, comfortable, and easy to work with. Fiberglass can be difficult to shape, may not provide the desired texture or visual appeal, and can be uncomfortable to sit or lie on. Instead, furniture manufacturers typically utilize materials such as wood, metal, plastic, upholstery fabrics, and foam for creating furniture pieces. These materials offer a wider range of options in terms of design, comfort, and customization, making them more suitable for furniture production.

- Q: How does fiberglass mat tissue compare to mineral wool insulation?

- Fiberglass mat tissue and mineral wool insulation are two common types of insulation materials used in construction and other industries. While both materials serve the purpose of providing thermal insulation, there are some differences between the two. Fiberglass mat tissue is made from fine glass fibers that are bonded together to form a mat. It is lightweight and flexible, making it easy to handle and install. Fiberglass mat tissue is also resistant to moisture, mold, and pests, making it a durable option for insulation. It has a high R-value, which measures the material's ability to resist heat flow, making it an effective insulator. On the other hand, mineral wool insulation is made from natural minerals such as basalt, diabase, or slag. It is typically denser and heavier than fiberglass mat tissue. Mineral wool insulation is known for its excellent fire resistance properties, as it is non-combustible and can withstand high temperatures. It also provides sound insulation, reducing noise transmission. However, mineral wool insulation can absorb moisture, which can reduce its effectiveness over time. In terms of thermal performance, both materials offer similar levels of insulation. However, fiberglass mat tissue tends to be slightly more efficient due to its higher R-value. Additionally, fiberglass mat tissue is generally more affordable compared to mineral wool insulation. In conclusion, fiberglass mat tissue and mineral wool insulation are both effective insulation materials. The choice between the two will depend on specific project requirements, such as fire resistance, sound insulation, cost, and moisture resistance. It is important to consider these factors and consult with professionals to determine the most suitable insulation material for a particular application.

- Q: Can fiberglass mat tissue be used for insulating ductwork?

- Indeed, insulating ductwork can be accomplished by employing fiberglass mat tissue. This insulation material is characterized by its composition of delicate glass fibers. Its lightweight and pliable nature facilitate effortless installation around ductwork, ensuring optimal thermal insulation. The outstanding insulating qualities of fiberglass mat tissue serve to minimize heat loss or gain within ducts, effectively enhancing energy efficiency. Additionally, it aids in condensation reduction and noise attenuation. Furthermore, its resistance to moisture, fire, and pests renders fiberglass mat tissue a fitting option for insulating ductwork in diverse environments.

- Q: Can fiberglass mat tissue be used for interior decoration?

- Yes, fiberglass mat tissue can be used for interior decoration. Fiberglass mat tissue is a versatile material that can be used for various purposes, including interior decoration. It is commonly used as a reinforcement material for composite materials, such as fiberglass reinforced plastic (FRP), which can be used to create decorative elements like panels, wall coverings, and moldings. Fiberglass mat tissue is lightweight, durable, and has excellent strength and resistance to moisture and chemicals. It can be easily molded into different shapes and designs, making it a popular choice for interior decoration projects. Additionally, fiberglass mat tissue can be coated or painted to match any desired color or texture, allowing for a wide range of creative possibilities in interior design.

- Q: Can fiberglass mat tissue be used for repairing fiberglass truck beds?

- Yes, fiberglass mat tissue can be used for repairing fiberglass truck beds. It is commonly used in such repairs due to its strength, durability, and ability to bond well with the existing fiberglass surface.

Send your message to us

Fiberglass Mat Tissue Fiberglass Woven Roving Combo Mat 1050gsm, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords