Fiberglass Mat Tissue C-Glass Woven Roving for Pultrusion

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

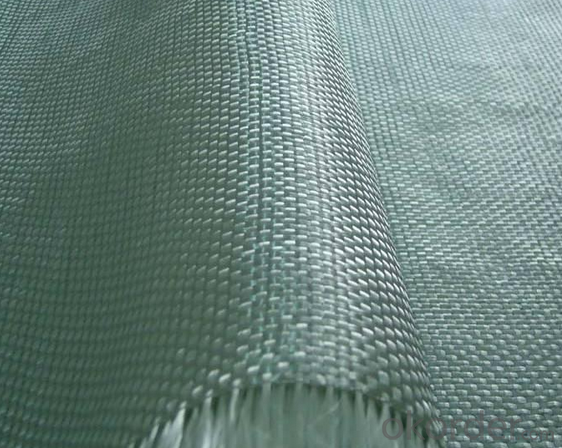

Structure of Woven Roving

1)Low Fuzz

2)Fast Wet-out&Impregnation

3)Easy Lay-up&Air Release

4)Excellent Mechanical Strength

5)Good Wet Strength Retension

6)Good Laminate Transparency

Main Features of Woven Roving

1.CWR400

2.360-380g/m2

3.77.5px or 2250px width

4.plastic woven bag

Application of Woven Roving

Unit | Product No. | Weight(gsm) | Technique | Moisture content | combustible matter content(%) |

M | EWR260 | 264±13 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR270 | 261±13.5 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR360 | 354±18 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR500 | 504±25 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR580 | 576±29 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR600 | 622±30 | Plain | ≤0.15 | 0.40-0.80 |

M | EWR800 | 850±40 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR200 | 200±15 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR400 | 385±30 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR600 | 600±45 | Plain | ≤0.15 | 0.40-0.80 |

M | CWR800 | 810±40 | Plain | ≤0.15 | 0.40-0.80 |

Images:

FAQ of Woven Roving

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Can fiberglass mat tissue be used for insulation in oil refineries?

- Yes, fiberglass mat tissue can be used for insulation in oil refineries. It is commonly used due to its excellent thermal insulation properties, resistance to high temperatures, and resistance to chemical corrosion.

- Q: How is fiberglass mat tissue used in the production of windshields?

- Fiberglass mat tissue is a crucial component in the production of windshields due to its unique properties and functions. When manufacturing windshields, the fiberglass mat tissue is used as a reinforcement material to enhance the strength and durability of the glass. During the production process, a layer of fiberglass mat tissue is inserted between two layers of glass to create a laminated structure. This layer acts as a barrier, preventing the glass from shattering into small dangerous pieces upon impact. It helps to hold the glass together, providing safety to the vehicle occupants. The fiberglass mat tissue serves as a reinforcing material, improving the mechanical properties of the windshield. It enhances the impact resistance, making the windshield less prone to cracks or chips from stones, debris, or other objects that may hit it while driving. This reinforcement also adds structural integrity to the windshield, allowing it to withstand extreme weather conditions and vibrations without compromising its functionality. Furthermore, the fiberglass mat tissue helps to reduce noise transmission and vibrations. It has sound-damping properties, which contribute to a quieter and more comfortable driving experience by reducing external noise from entering the vehicle cabin. Additionally, the use of fiberglass mat tissue allows for the production of curved windshields. The flexibility of the material enables it to conform to different shapes and contours, allowing manufacturers to create windshields with customized designs and improved aerodynamics. In summary, fiberglass mat tissue plays a vital role in the production of windshields. Its reinforcement properties enhance the strength and impact resistance of the glass, providing safety to the vehicle occupants. It also contributes to a quieter driving experience and enables the production of curved windshields with improved aerodynamics.

- Q: Can fiberglass mat tissue be used for architectural facades?

- Indeed, architectural facades can make use of fiberglass mat tissue. This lightweight and flexible material finds wide application in diverse construction projects, including architectural facades. It boasts numerous benefits, ranging from its impressive strength and durability to its exceptional resistance against weather and fire. Moreover, fiberglass mat tissue lends itself easily to molding into various shapes and sizes, thus proving suitable for intricate and distinctive architectural designs. Its adaptability and visual allure render it a favored option among architects and designers when aiming to fashion visually pleasing and practical facades.

- Q: Can fiberglass mat tissue be used for acoustic insulation?

- Yes, fiberglass mat tissue can be used for acoustic insulation. Fiberglass mat tissue is a lightweight material that has excellent sound absorption properties. It can effectively absorb and dampen sound waves, reducing noise and improving the acoustic environment. Fiberglass mat tissue is commonly used in the construction industry for insulating walls, ceilings, and floors to reduce noise transmission. It is also used in automotive applications and other industries where sound insulation is required. Its high porosity and fibrous structure make it an ideal material for absorbing and attenuating sound waves, making it suitable for acoustic insulation.

- Q: Can fiberglass mat tissue be used for making fiberglass molds?

- Yes, fiberglass mat tissue can be used for making fiberglass molds. Fiberglass mat tissue is a lightweight material made from randomly oriented fiberglass strands. It is commonly used in composite manufacturing to provide additional strength and reinforcement to fiberglass laminates. When making fiberglass molds, the mat tissue can be used as a surface layer to create a smooth and durable finish. It helps to prevent air bubbles, improve the overall strength of the mold, and provide a good surface for the application of release agents or gel coats. However, it is important to note that fiberglass mat tissue alone may not be sufficient to create a rigid and durable mold. It is often used in combination with other fiberglass materials, such as chopped strand mat or woven roving, to provide additional strength and thickness to the mold. Overall, fiberglass mat tissue can be a useful component in making fiberglass molds, but it is typically used in conjunction with other materials to achieve the desired properties.

- Q: Can fiberglass mat tissue be used for ceiling insulation?

- Ceiling insulation requires specific materials that are more suitable and effective, such as fiberglass batts, cellulose, or foam insulation. These materials are designed to provide thermal resistance and reduce heat transfer between the interior and exterior of a building. Using fiberglass mat tissue for ceiling insulation is not recommended as it is not designed for insulation purposes. It is commonly used in construction applications like reinforcing plaster or other building materials, but it lacks the necessary thickness to effectively insulate ceilings. In addition, fiberglass insulation materials can pose safety risks as they release airborne particles and fibers that can be harmful if inhaled. Therefore, it is crucial to use insulation materials specifically engineered for ceiling insulation to ensure energy efficiency, comfort, and safety in your home or building.

- Q: Can fiberglass mat tissue be used for insulating windows?

- No, fiberglass mat tissue is not suitable for insulating windows. It is primarily used for reinforcing and strengthening surfaces, such as in the construction industry, and is not designed to provide thermal insulation.

- Q: How is fiberglass mat tissue used in the production of water tanks?

- Fiberglass mat tissue is used in the production of water tanks to provide reinforcement and durability. It is applied as a layer between the inner and outer walls of the tank to enhance its structural integrity and prevent leakage. The fiberglass mat tissue acts as a barrier against corrosion, increases the tank's resistance to external factors such as temperature changes and chemicals, and improves its overall strength.

- Q: Can fiberglass mat tissue be used in wet environments?

- Yes, fiberglass mat tissue can be used in wet environments. It is resistant to water and can withstand exposure to moisture without losing its structural integrity.

- Q: How is fiberglass mat tissue manufactured?

- Fiberglass mat tissue is manufactured through a multi-step process that involves the use of glass fibers and a binder material. The first step in the manufacturing process is the production of glass fibers. This is typically done by melting raw materials such as silica sand, limestone, and soda ash in a furnace. The molten glass is then forced through tiny holes in a spinneret, which creates fine strands of glass fibers. Once the glass fibers are produced, they are pulled together to form a continuous mat. This is achieved by passing the fibers through a series of rollers or air jets that align and compress the fibers into a uniform sheet. At this stage, the mat is still loose and fragile. To give the fiberglass mat tissue its strength and stability, a binder material is added. This binder can be a resin or a combination of resins and additives. The binder is typically sprayed onto the mat, allowing it to penetrate and bond with the glass fibers. This process is known as wet-laid manufacturing. After the binder is applied, the fiberglass mat tissue goes through a curing process. This can involve the use of heat, pressure, or both, depending on the specific requirements of the product. The curing process helps to harden the binder and ensure that it securely holds the glass fibers together, creating a strong and durable mat. Once the curing process is complete, the fiberglass mat tissue is dried to remove any excess moisture. It is then trimmed and cut into the desired dimensions. Depending on the intended application, the mat may undergo additional treatments such as surface coatings or laminations to enhance its performance properties. Overall, the manufacturing process of fiberglass mat tissue involves the production of glass fibers, the formation of a continuous mat, the addition of a binder material, curing, drying, and final processing. This process ensures that the resulting fiberglass mat tissue is strong, flexible, and suitable for a wide range of applications such as insulation, reinforcement in composites, or roofing materials.

Send your message to us

Fiberglass Mat Tissue C-Glass Woven Roving for Pultrusion

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords