High Quality Fiberglass Mat Tissue - Good Sell Glass Wool Insulation at Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

With excellent rebound property, our glass wool, when reachs the destination, will rebound almost to the original level in 24 hours after been unpacked.

CNBM is one of the largest glass wool manufacturers in China. we produce glass wool with excellent quality. Various color and sizes are available.

Our glass wool is made of pure non-colour glass flat board as raw material, which come directly from flat glass factories, we do not use cycled glass wool it used for thermal insulation for partition walls, wall interior partitions, train compartment , steal structures and sound absorption for buildings.

2.Main features of Glass Wool Blanket:

1.Economical insulating material

2.Light and easy to install

3.Heat and cold insulation

3.Sound absorption material

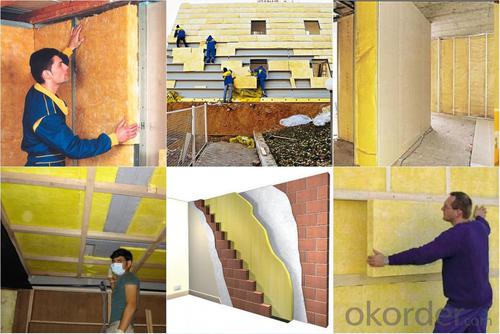

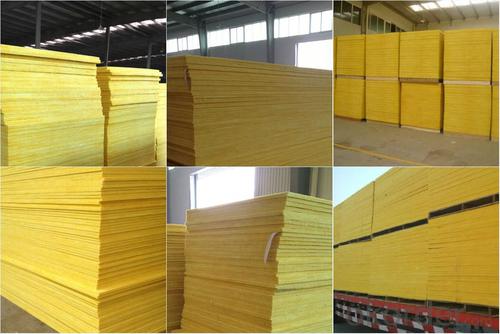

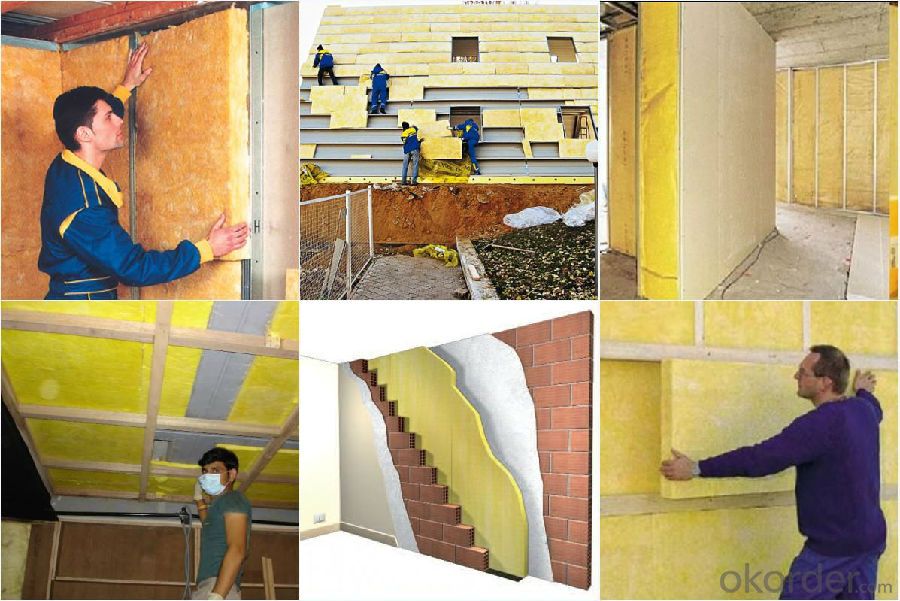

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue suitable for outdoor applications?

- Yes, fiberglass mat tissue is suitable for outdoor applications. It is highly durable, weather-resistant, and can withstand exposure to harsh environmental conditions such as sunlight, rain, and extreme temperatures. Additionally, it provides excellent strength and insulation properties, making it a reliable choice for various outdoor applications, including construction, roofing, and insulation.

- Q: How long does fiberglass mat tissue last?

- The lifespan of fiberglass mat tissue varies depending on various factors such as the quality of the material, environmental conditions, and maintenance. However, on average, fiberglass mat tissue can last for several decades if properly installed and cared for.

- Q: Is fiberglass mat tissue suitable for architectural applications?

- Fiberglass mat tissue is indeed appropriate for architectural purposes. It is a lightweight and adaptable material frequently employed in construction and architectural undertakings. Its exceptional strength and durability make it well-suited for a variety of architectural applications, including wall cladding, roofing, insulation, and decorative panels. Moreover, fiberglass mat tissue possesses resistance to water, chemicals, and fire, further augmenting its appropriateness for architectural utilization. Given its versatility, it can be easily molded into diverse shapes and sizes, granting architects significant design flexibility. In conclusion, fiberglass mat tissue is a dependable and efficient material that can be effectively employed in architectural applications.

- Q: Does fiberglass mat tissue provide any moisture insulation?

- Fiberglass mat tissue indeed offers a certain degree of moisture insulation. Renowned for its water-resistant attributes, fiberglass, when transformed into mat tissue, bolsters this quality even more. By serving as a protective shield, it thwarts the infiltration of moisture, averting potential harm to underlying substances. Nevertheless, it is crucial to recognize that fiberglass mat tissue does not possess absolute waterproofing abilities and might permit some moisture penetration over prolonged periods. Consequently, it is advisable to incorporate supplementary moisture insulation materials in scenarios demanding comprehensive waterproofing.

- Q: What is the specific gravity of fiberglass mat tissue?

- The specific gravity of fiberglass mat tissue typically ranges between 1.5 and 2.0.

- Q: Can fiberglass mat tissue be used for insulating windows?

- Certainly! Insulating windows is possible with the utilization of fiberglass mat tissue. This lightweight and adaptable material is frequently employed for insulation objectives. With its commendable thermal resistance, it effectively diminishes the escape or entry of heat through windows. By simply affixing a layer of fiberglass mat tissue onto the window surface, it greatly enhances the window's insulation capabilities, thereby reducing drafts and heat transfer. Moreover, this multifunctional fiberglass mat tissue also effectively minimizes noise transmission, rendering it a versatile choice for both thermal and acoustic insulation purposes.

- Q: How does fiberglass mat tissue compare to polystyrene insulation?

- Fiberglass mat tissue and polystyrene insulation are two different materials used for insulation purposes, and they have their own distinct characteristics and benefits. Fiberglass mat tissue is made from thin strands of glass fibers that are woven together to form a mat. It is commonly used in applications where heat and sound insulation is required. Fiberglass mat tissue is known for its excellent thermal insulation properties, as it can effectively resist heat transfer, making it suitable for both hot and cold environments. Additionally, it is resistant to moisture and does not promote the growth of mold or mildew. On the other hand, polystyrene insulation is a foam material made from expanded polystyrene beads. It is widely used in the construction industry as it provides good thermal insulation and can be easily shaped or cut to fit various spaces. Polystyrene insulation is known for its high compressive strength, making it ideal for load-bearing applications. It is also moisture-resistant, lightweight, and has excellent resistance to aging and degradation. When comparing fiberglass mat tissue to polystyrene insulation, there are a few key differences to consider. Fiberglass mat tissue is generally more flexible and can be easier to install in irregular or curved surfaces. It is also more resistant to fire, as it does not burn or release toxic gases when exposed to flames. However, fiberglass mat tissue can be more expensive than polystyrene insulation and may require additional protective measures, such as wearing gloves and masks during installation, due to its potential for skin and respiratory irritation. Polystyrene insulation, on the other hand, is less expensive and easier to handle and install compared to fiberglass mat tissue. It also has better moisture resistance, which makes it suitable for applications in areas with high humidity or potential water exposure. However, polystyrene insulation is more flammable than fiberglass mat tissue and can release toxic gases when burned. In conclusion, the choice between fiberglass mat tissue and polystyrene insulation depends on the specific requirements of the insulation project. Fiberglass mat tissue is well-suited for its excellent thermal insulation properties, fire resistance, and resistance to moisture and mold. Polystyrene insulation, on the other hand, offers good thermal insulation, ease of installation, and high compressive strength. Ultimately, it is important to consider factors such as cost, installation requirements, fire resistance, and moisture resistance when deciding between fiberglass mat tissue and polystyrene insulation.

- Q: Can fiberglass mat tissue be used for repairing fiberglass fenders?

- Fiberglass fenders can be repaired using fiberglass mat tissue. This versatile material is commonly employed in fiberglass repair tasks, serving as a reinforcement layer to enhance strength and durability in the repaired region. To mend damaged or cracked areas of fiberglass fenders, one can apply a resin layer and then lay the fiberglass mat tissue on top. By saturating the mat tissue with additional resin, a strong bond is formed, ensuring a smooth finish. This restorative process not only revitalizes the fender's structural integrity but also delivers a seamless repair. It is worth noting, however, that the extent of the damage and the expertise of the repairer ultimately determine the success of the repair.

- Q: Can fiberglass mat tissue be used for making insulation boards?

- Yes, fiberglass mat tissue can be used for making insulation boards. The tissue provides strength, stability, and reinforcement to the insulation material, making it an effective choice for insulation board manufacturing.

- Q: Can fiberglass mat tissue be used for repairing automotive parts?

- Certainly, automotive parts can be repaired using fiberglass mat tissue. This versatile material is commonly employed to reinforce and repair various surfaces, including automotive components. It proves particularly valuable when restoring fiberglass parts such as car bodies and panels. Fiberglass mat tissue possesses a thin and flexible composition, comprised of randomly arranged fiberglass strands. This design enables easy molding and shaping to match the contours of the damaged automotive part. Typically, the mat tissue is applied alongside a resin like polyester or epoxy, which binds the fibers together, yielding a robust and enduring repair. When utilized for automotive repairs, fiberglass mat tissue offers numerous advantages. Firstly, its lightweight nature is crucial for maintaining the overall weight and balance of the vehicle. Furthermore, it exhibits resistance to corrosion and can withstand exposure to diverse weather conditions, rendering it suitable for all automotive repair applications. Moreover, fiberglass mat tissue is renowned for its high tensile strength, enabling it to endure the stresses and strains encountered during normal use of automotive parts. As a result, it becomes an ideal choice for fixing damaged or weakened areas, such as cracks, holes, or dents in car bodies or panels. In conclusion, fiberglass mat tissue is a highly effective option for repairing automotive parts, especially those constructed from fiberglass. Its versatility, lightweight composition, corrosion resistance, and high tensile strength make it an exceptional choice for restoring the structural integrity and appearance of damaged automotive components.

Send your message to us

High Quality Fiberglass Mat Tissue - Good Sell Glass Wool Insulation at Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords