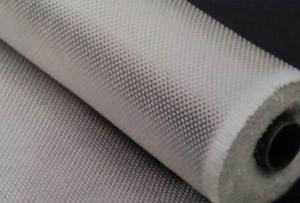

E Glass Woven Roving Fiberglass Mat Tissue

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

E-Glass Woven Rovings are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E-Glass Woven Rovings are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

Characteristics

Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

Densely aligned fibers, resulting in high dimensional stability and making handling easy

Product Specifications

Property | Area Weight | Moisture Content | Size Content | Width |

(%) | (%) | (%) | (mm) | |

Test Method | IS03374 | ISO3344 | ISO1887 | |

EWR200 | ±7.5 | ≤0.15 | 0.4-0.8 | 20-3000 |

EWR270 | ||||

EWR300 | ||||

EWR360 | ||||

EWR400 | ||||

EWR500 | ||||

EWR600 | ||||

EWR800 |

Special specification can be produce according to customer requirements.

FAQ

Packaging:Each woven roving is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 220mm. The woven roving roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Is fiberglass mat tissue suitable for underground applications?

- Fiberglass mat tissue is perfect for use underground. This material is widely utilized in various industries like construction, infrastructure, and plumbing because of its exceptional strength, durability, and ability to resist environmental factors. Underground environments often present difficulties such as moisture, high humidity, and corrosive substances, which can compromise traditional materials. However, fiberglass mat tissue is specifically designed to endure these conditions, making it an excellent choice for underground applications. Moreover, its non-combustible nature and resistance to chemicals ensure it is a dependable option for areas where fire safety is a concern. In conclusion, fiberglass mat tissue is a versatile and reliable material that can effectively endure the challenges of underground environments.

- Q: Does fiberglass mat tissue absorb water?

- Indeed, water can be absorbed by fiberglass mat tissue. Comprised of delicate interwoven and bonded glass fibers, this tissue possesses the capacity to absorb water. Nevertheless, it does not retain the moisture for extended durations. Once fiberglass mat tissue comes into contact with water, the fibers absorb the liquid, resulting in the tissue becoming damp. However, it is important to note that fiberglass as a material is not susceptible to water damage, given that its non-porous fibers do not deteriorate when exposed to moisture.

- Q: How is fiberglass mat tissue used in the production of shower enclosures?

- Fiberglass mat tissue is used in the production of shower enclosures to reinforce the structure and provide added strength. It is typically applied as a layer between the gel coat and the fiberglass resin, creating a durable and rigid surface that can withstand daily use and potential impacts. The fiberglass mat tissue helps prevent cracking and warping, ensuring the shower enclosure maintains its shape and integrity over time.

- Q: What are the different types of resins compatible with fiberglass mat tissue?

- There are several different types of resins that are compatible with fiberglass mat tissue. These resins include polyester resin, epoxy resin, vinyl ester resin, and polyurethane resin. Polyester resin is one of the most commonly used resins in fiberglass mat applications. It is cost-effective and has good mechanical properties, making it suitable for a wide range of applications. Polyester resin is also easy to work with and provides good resistance to water and chemicals. Epoxy resin is another popular choice for fiberglass mat tissue. It offers excellent mechanical properties, high strength, and good resistance to chemicals and moisture. Epoxy resin is often used in applications that require superior strength and durability, such as aerospace and marine industries. Vinyl ester resin is a hybrid between polyester and epoxy resins. It combines the best properties of both resins, offering high strength, good corrosion resistance, and excellent durability. Vinyl ester resin is commonly used in applications where high chemical resistance and superior mechanical properties are required. Polyurethane resin is a versatile resin that can be used with fiberglass mat tissue. It offers excellent flexibility, impact resistance, and adhesion properties. Polyurethane resin is often used in applications that require high flexibility and resistance to abrasion, such as automotive parts and sporting goods. Overall, the choice of resin depends on the specific requirements of the application, including mechanical properties, chemical resistance, flexibility, and cost.

- Q: Can fiberglass mat tissue be used for ballistic protection?

- While fiberglass mat tissue can offer some degree of ballistic protection, it may not provide the same level of safety as materials specifically created for this purpose. Its exceptional strength and resistance to heat make it ideal for insulation, reinforcement, and fire resistance applications. Nevertheless, when it comes to shielding against ballistic threats, there are specialized materials engineered to endure the impact of bullets or projectiles. These materials, such as aramid fibers (like Kevlar) or ultra-high-molecular-weight polyethylene fibers (like Dyneema), are far more effective in delivering superior ballistic protection. Therefore, if the primary concern is ballistic protection, it is advisable to opt for materials designed explicitly for this purpose rather than relying solely on fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for insulation in cleanrooms?

- Yes, fiberglass mat tissue can be used for insulation in cleanrooms. It is a commonly used material due to its excellent thermal insulation properties, low cost, and high resistance to chemicals and moisture. Additionally, fiberglass mat tissue has low particulate emission, making it suitable for cleanroom environments where maintaining a controlled and sterile atmosphere is crucial.

- Q: What is the shear strength of fiberglass mat tissue?

- The shear strength of fiberglass mat tissue depends on various factors such as the thickness of the mat, the type and quality of the fiberglass material used, and the manufacturing process. However, in general, fiberglass mat tissue has a relatively high shear strength compared to other materials. Fiberglass mat tissue is typically composed of multiple layers of glass fibers bonded together with a resin matrix. The combination of these materials results in a strong and durable product. The shear strength of fiberglass mat tissue allows it to withstand significant forces and resist deformation or failure when subjected to shear stress. To determine the specific shear strength of a particular fiberglass mat tissue, it is necessary to refer to the product specifications provided by the manufacturer. These specifications typically include information about the material's shear strength, as well as other mechanical properties. It is important to note that the shear strength of fiberglass mat tissue can vary depending on the specific application and conditions in which it is used. Factors such as temperature, moisture, and exposure to chemicals can influence the material's performance. Therefore, it is always recommended to consult the manufacturer's guidelines and engineering experts to ensure the proper selection and application of fiberglass mat tissue for a particular project.

- Q: Can fiberglass mat tissue be used in corrosive environments?

- Fiberglass mat tissue can be used in corrosive environments to some extent, but its resistance to corrosion depends on the specific composition and quality of the material. Fiberglass mat tissue is typically manufactured using a combination of fiberglass strands and a binder material. While fiberglass itself is generally resistant to corrosion, the binder material used in the mat tissue can vary and affect its resistance to corrosive environments. Some binders may provide better protection against corrosion, while others may be more susceptible to degradation. To enhance the corrosion resistance of fiberglass mat tissue in corrosive environments, additional protective coatings or treatments can be applied. These coatings can provide a barrier against the corrosive elements and extend the lifespan of the material. It is important to consider the specific corrosive environment and consult with experts or manufacturers to determine the suitability of fiberglass mat tissue for a particular application. They can provide guidance on the ideal composition, treatment, and any necessary precautions to ensure optimal performance and durability in corrosive environments.

- Q: Is fiberglass mat tissue resistant to mildew and rot?

- Yes, fiberglass mat tissue is resistant to mildew and rot. Fiberglass is made from fine glass fibers that are woven together to create a strong and durable material. These fibers are non-porous and do not absorb moisture, making fiberglass mat tissue highly resistant to the growth of mildew and the decomposition caused by rot. Additionally, fiberglass is often coated with protective finishes or treated with additives that further enhance its resistance to these types of biological degradation. This makes fiberglass mat tissue an excellent choice for applications where moisture or humidity is a concern, such as in bathrooms, outdoor structures, or areas prone to high humidity.

- Q: Can fiberglass mat tissue be painted over?

- Yes, fiberglass mat tissue can be painted over. However, there are a few considerations that need to be taken into account. First, it is important to ensure that the fiberglass mat tissue is clean and free from any dirt, grease, or other contaminants before painting. This can be achieved by cleaning the surface with a mild detergent and water, followed by thorough rinsing and drying. Secondly, it is recommended to apply a primer before painting to improve adhesion and promote a smoother finish. A high-quality primer specifically designed for use on fiberglass surfaces should be used, following the manufacturer's instructions for application. Finally, when choosing the paint, it is crucial to select one that is compatible with fiberglass materials. Acrylic or epoxy-based paints are often recommended as they provide good adhesion and durability on fiberglass surfaces. By following these steps and using appropriate materials, it is possible to paint over fiberglass mat tissue successfully. However, it is always advisable to consult with a professional or follow the manufacturer's recommendations for optimal results.

Send your message to us

E Glass Woven Roving Fiberglass Mat Tissue

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords