Fiberglass Mat Tissue Woven Roving Combo Mat 980gsm, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Process

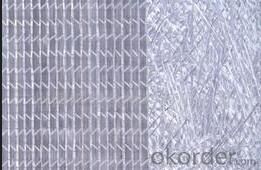

Fiberglass stitch combo mat is the mat combining the woven roving and a even layer of chopped strand mat with polyester yarn.

Properties

• Fiber level unfolded without cross, high density, high utilizing rate.

• Multi-layer finished one time, decrease layer and enhance efficiency.

• Providing the product with multi-directional mechanical strength.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Specifications

specifications | Fibre type | Wover roving | Chopped strand | Overall weight | Width |

(g/㎡) | (g/㎡) | (g/㎡) | (mm) | ||

EMK 600/300 | E-Glass | 600 | 300 | 900 | 1600/2400 |

EMK 600/380 | E-Glass | 600 | 380 | 980 | 1600/2400 |

EMK 600/450 | E-Glass | 600 | 450 | 1050 | 1600/2400 |

EMK 800/300 | E-Glass | 800 | 300 | 1100 | 1600/2400 |

EMK 800/380 | E-Glass | 800 | 380 | 1180 | 1600/2400 |

EMK 800/450 | E-Glass | 800 | 450 | 1250 | 1600/2400 |

Packaging: Wrapped in PVC and placed within a cardboard carton. | |||||

- Q: Can fiberglass mat tissue be used for lightweight construction?

- Fiberglass mat tissue is a fantastic option for lightweight construction. This thin and lightweight material is composed of glass fibers that are randomly arranged and held together with a binder. It is commonly utilized as a reinforcement material in composite laminates and is renowned for its impressive strength-to-weight ratio. When it comes to lightweight construction, where minimizing weight is crucial, fiberglass mat tissue is an excellent selection. Its minimal weight adds little burden to the structure while still providing ample strength and durability. The random arrangement of fibers in the mat tissue guarantees even distribution of the load, further enhancing its strength properties. Furthermore, handling fiberglass mat tissue is a breeze, and it can be effortlessly molded into various shapes and forms. Its flexibility makes it suitable for lightweight construction applications such as creating lightweight panels, wall partitions, and roof structures. The material can also be combined with other lightweight materials like foam cores or honeycomb structures to further elevate its lightweight characteristics. In summary, fiberglass mat tissue is an adaptable material that can be effectively employed in lightweight construction. Its lightweight nature, coupled with its strength and durability, make it a fitting choice for a wide range of applications where weight reduction is a top priority.

- Q: How long does fiberglass mat tissue last?

- The lifespan of fiberglass mat tissue can vary depending on various factors such as its quality, usage, and exposure to external conditions. Generally, fiberglass mat tissue is designed to be highly durable and long-lasting. When properly installed and maintained, it can typically last for several decades. However, it is important to note that fiberglass mat tissue can deteriorate over time due to environmental factors such as UV exposure, moisture, and temperature fluctuations. Continuous exposure to harsh weather conditions, extreme temperatures, or chemicals can accelerate the degradation process. To maximize the lifespan of fiberglass mat tissue, it is crucial to follow the manufacturer's guidelines for installation, maintenance, and periodic inspections. Regular inspections can help identify any signs of wear, damage, or degradation early on, allowing for timely repairs or replacements. It is recommended to consult with a professional or the manufacturer for specific information regarding the expected lifespan of a particular fiberglass mat tissue, as it can vary depending on the specific product and its intended application.

- Q: How does fiberglass mat tissue perform in high temperatures?

- Due to its inherent heat resistance properties, fiberglass mat tissue is highly effective in high temperatures. The mat is crafted from woven glass fibers, creating a durable and sturdy material. These glass fibers possess a high melting point, enabling the fiberglass mat tissue to endure elevated temperatures without distorting or compromising its structural integrity. Unlike other materials, fiberglass mat tissue does not shrink, warp, or become brittle when exposed to high temperatures. It maintains its dimensional stability and mechanical strength, making it suitable for a wide range of applications in industries such as automotive, aerospace, construction, and insulation. Furthermore, fiberglass mat tissue acts as a thermal insulator, providing protection against heat transfer. It effectively resists heat conduction and radiation, assisting in maintaining the desired temperature in a given environment or preventing heat damage to nearby components. Moreover, fiberglass mat tissue is non-combustible, meaning it does not burn or release toxic gases when subjected to fire. This characteristic makes it a dependable choice for applications that necessitate fire resistance, such as fireproofing insulation or protective barriers. In conclusion, fiberglass mat tissue excels in high temperatures. Its heat resistance, dimensional stability, mechanical strength, thermal insulation properties, and non-combustible nature establish it as an outstanding material for demanding environments where elevated temperatures are present.

- Q: How does the roll weight of fiberglass mat tissue affect its transportation?

- The roll weight of fiberglass mat tissue can have a significant impact on its transportation process. The weight of the roll determines the ease of handling and the logistics required for transportation. Firstly, a heavier roll weight can make it more challenging to move and handle the fiberglass mat tissue. If the roll is too heavy, it may require specialized equipment or machinery for loading and unloading, such as forklifts or cranes. This can add complexity and cost to the transportation process. Moreover, the weight of the roll also affects the packaging and storage requirements during transportation. Heavier rolls may require sturdier packaging materials and additional precautions to ensure their stability and prevent any damage during transit. This can include using pallets, strapping, or other securing methods to prevent the roll from shifting or falling during transportation. The weight of the roll also impacts the overall cost of transportation. Heavier rolls can increase shipping costs, as carriers often charge based on weight. Additionally, the weight of the roll can affect the number of rolls that can be transported in a single shipment, which can impact the efficiency and cost-effectiveness of the transportation process. In summary, the roll weight of fiberglass mat tissue plays a crucial role in its transportation. It affects the ease of handling, packaging requirements, and overall cost of transportation. Therefore, it is essential to consider the roll weight when planning and organizing the logistics for transporting fiberglass mat tissue.

- Q: What is the fire rating of fiberglass mat tissue?

- The fire rating of fiberglass mat tissue can vary depending on its specific composition and intended application. However, fiberglass mat tissue typically has a good fire resistance rating due to the inherent properties of fiberglass, such as its high melting point and non-combustible nature. It is often used in fire-rated applications where fire protection is required.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- When considering soundproofing, fiberglass mat tissue offers potential benefits but its effectiveness will vary based on specific needs and desired soundproofing levels. Fiberglass mat tissue is a versatile and lightweight material that effectively absorbs and dampens sound waves. It possesses favorable acoustic properties and can aid in reducing noise transmission, making it a viable choice for soundproofing applications. However, it is important to note that fiberglass mat tissue alone may not deliver adequate soundproofing, particularly in environments with high levels of noise. To achieve optimal results, it is advisable to combine it with other soundproofing materials like acoustic foam panels or mass-loaded vinyl to enhance its soundproofing capabilities. Furthermore, the thickness and density of the fiberglass mat tissue can impact its sound absorption properties. Generally, thicker and denser mats are more effective in attenuating sound waves, but they may also present challenges in terms of flexibility and installation. In summary, while fiberglass mat tissue can contribute to soundproofing endeavors, its suitability depends on specific requirements, desired soundproofing levels, and the incorporation of additional materials. It is advisable to consult a soundproofing expert or conduct comprehensive research on the particular application to determine the most suitable solution for achieving effective soundproofing.

- Q: Can fiberglass mat tissue be used for repairing fiberglass fenders?

- Yes, fiberglass mat tissue can be used for repairing fiberglass fenders. Fiberglass mat tissue is a versatile material that is commonly used in fiberglass repair work. It is often used as a reinforcement layer to add strength and durability to the repaired area. When repairing fiberglass fenders, the damaged or cracked area can be repaired by applying a layer of resin and then laying the fiberglass mat tissue over it. The mat tissue is then saturated with additional resin to create a strong bond and ensure a smooth finish. This process helps to restore the structural integrity of the fender and provide a seamless repair. However, it is important to note that the success of the repair depends on the extent of the damage and the skill of the person performing the repair.

- Q: Is fiberglass mat tissue recyclable?

- Indeed, fiberglass mat tissue can be recycled. It is crafted from a fusion of glass fibers and typically resin, serving as a binding material. Once the material becomes unnecessary or completes its life span, it can undergo recycling by disassembling the glass fibers from the binder material. Subsequently, the glass fibers can be liquefied and utilized in the production of novel fiberglass goods, while the binder material can be processed and repurposed in alternative applications. The act of recycling fiberglass mat tissue aids in waste reduction and the preservation of natural resources, rendering it a sustainable choice.

- Q: Can fiberglass mat tissue be used for insulation in power plants?

- Yes, fiberglass mat tissue can be used for insulation in power plants. Fiberglass mat tissue is a lightweight and flexible material that is known for its excellent thermal insulation properties. It is often used as a thermal barrier to reduce heat transfer in various applications, including power plants. By insulating the equipment and pipes, fiberglass mat tissue helps to prevent heat loss and increase energy efficiency in power plants. Additionally, fiberglass mat tissue is non-combustible, making it a suitable choice for insulation in environments where fire safety is paramount.

- Q: Can fiberglass mat tissue be used in marine applications?

- Yes, fiberglass mat tissue can be used in marine applications. It is commonly used in boat building and repair due to its excellent strength, corrosion resistance, and durability in marine environments.

Send your message to us

Fiberglass Mat Tissue Woven Roving Combo Mat 980gsm, 1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords